Vacuum Casting Services

Formioo offers custom polyurethane parts, from prototype design to small batch production. Delivery is as fast as 5 days.

- Get a free instant quote

- Durable, production-grade quality parts

- Tolerance 0.01mm

- An experienced team of casting engineers will guide you through the entire process

Reliable Vacuum Casting Manufacturer from China

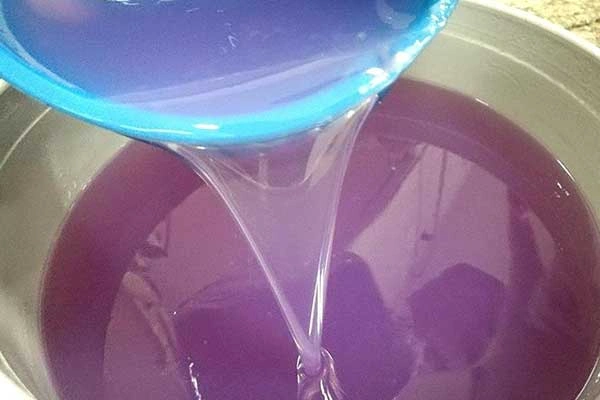

Formioo is a professional injection molding manufacturer in China, offering vacuum casting services for high-quality, low-volume plastic parts with an injection-molded appearance. With dedicated vacuum casting equipment, silicone molding workshops, and precision pattern-making capabilities, we help customers bring functional, presentation-ready parts to life in a matter of days.

Our vacuum casting process is ideal for rapid prototyping, concept verification, and short-run production. It supports fast design iteration, reduces upfront tooling investment, and allows for low minimum order quantities, typically starting from just several units. The process delivers smooth surface finishes, consistent part geometry, and tight visual tolerances, perfect for user testing, demo builds, or early market validation without delay.

With over a decade of manufacturing experience, Formioo produces thousands of vacuum-cast parts each year for clients across the automotive, medical, electronics, robotics, and consumer product sectors. We provide flexible production capacity, short lead times, and stable quality, ensuring every low-volume order receives professional-grade results.

Our Vacuum Casting Services

Formioo offers a full range of vacuum casting services, including rapid prototyping vacuum casting, high-precision vacuum casting, functional vacuum casting, and multi-cavity vacuum casting. These processes are ideal for producing high-quality plastic parts with an injection-molded appearance and tight dimensional consistency. We work with a wide variety of polyurethane casting resins that simulate ABS, PC, PP, PA, rubber-like, and even transparent materials, suitable for both visual models and functional components.

To meet different cosmetic and mechanical needs, we provide post-processing options such as polishing, painting, texture replication, silk screen printing, and color matching. Depending on the material and part complexity, our vacuum casting process can achieve tolerances as tight as ±0. 01 mm. All parts are cast in controlled environments and inspected for accuracy, surface quality, and uniformity, making our service a reliable choice for low-volume, high-fidelity parts.

Well-suited to the prototype, the method creates accurate, cost-effective parts with subtle surface details quickly by vacuum-supported resin casting.

This process provides outstanding dimensional tolerances and surface finish, best suited for functional testing and small-batch production of intricate parts.

Designed for end-product components, this process provides high-strength, high-grade parts with mechanical and aesthetic industry standards.

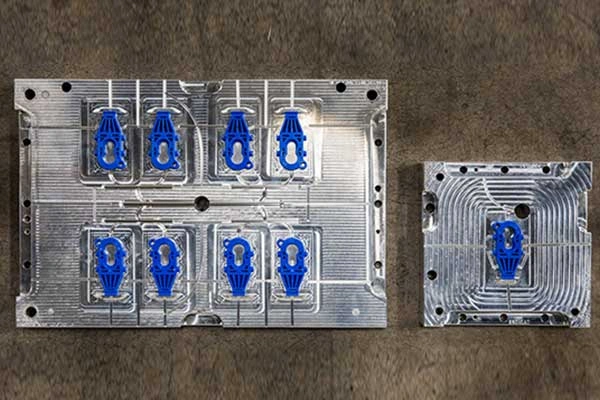

Optimized for mass production, multi-cavity casting uses multiple molds in one cycle to deliver consistent quality in high volumes of parts.

Vacuum Casting Capabilities

Material Compatibility

Our vacuum casting process employs superior materials like polyurethane, epoxy, and silicone to tackle numerous production needs.

Printing Accuracy

Achieves fine details with tolerances around ±0.05mm.

Maximum Build Size

Presents parts up to 500mm × 400mm × 300mm for small to medium series.

Surface Finishing Options

Has polishing, painting, and coating for improved appearance.

Delivery Time

Standard lead time is 5-10 days, with expedited options available.

Massive Network

We work with trusted vacuum casting suppliers.

This is Modal Title

[contact-form-7 id="852" title="Contact Us"]

Explore Our Latest Vacuum Casting Parts We Manufactured

Discover our expertly crafted vacuum cast parts and see the quality for yourself. Click here to view our finished products and experience precision and innovation in every piece.

Vacuum Casting Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Vacuum Cast Parts | +/- 0.2 mm to +/- 0.5 mm |

| Precision Vacuum Cast Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Vacuum Cast Parts | +/- 0.3 mm to +/- 0.8 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Vacuum Casting Materials

Polyester Resin

Quick cure and smooth surface finish, polyester resin is well suited for the production of decorative pieces and intricate models. It is applied in automotive emblems and consumer product model prototypes, finding a balance between cost and performance.

- Mill Lead Time: Up to 5 days

- Color: Translucent or pigmented options

Acrylic Resin

Renowned for its weather resistance and visual attractiveness, acrylic resin is a great choice for making transparent or colored decorative components. Due to its superior finish and clarity, it is used in display models and lighting.

- Mill Lead Time: Up to 4 days

- Color: Clear, colored, and matte finishes

Polyurethane Resin

Low viscosity and extremely fine reproduction of detail make it very suitable for vacuum casting, particularly rapid prototyping and low-volume production. It has wide application in automotive trim and consumer electronics enclosures for thin surface finish as well as resistance.

- Mill Lead Time: Up to 5 days

- Color: Customizable finishes available

Epoxy Resin

Having improved strength and transparency, epoxy resin provides high-performance structural components and optical components. Its excellent adhesion and low shrinkage enable precise, detailed molds for functional models and end-use applications.

- Mill Lead Time: Up to 7 days

- Color: Transparent and tinted options

Urethane Elastomer

With the flexibility of elastomers and the precision of vacuum casting, urethane elastomer is best utilized in flexible parts, soft-touch grips, and seals. Toughness and tear resistance also get extensive applications in car interiors and wearable accessories.

- Mill Lead Time: Up to 6 days

- Color: Neutral tones with custom pigmentation

Silicone Rubber

Very resistant to heat and flexible, silicone rubber is best utilized in the production of touch-sensitive components and delicate molds. It is employed in most applications by medical devices and wearable components with uniform performance under varying conditions.

- Mill Lead Time: Up to 6 days

- Color: Various neutral shades available

Finishing Options for Vacuum Casting

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Painting | Resins, Plastics, Metals | Any color (customizable) | Primer, Base Coat, Clear Coat |

|

Polishing | Resins, Plastics, Metals | Natural material color | Buffing wheels, Polishing compounds |

|

Media Blasting | Resins, Plastics, Metals | Matte finish (natural) | Sand, Glass Beads, Aluminum Oxide |

|

Electroplating | Conductive materials | Chrome, Gold, Nickel, etc. | Conductive coating, Electrolytic bath |

|

Anodizing | Aluminum | Clear, Black, Gold, etc. | Electrolytic process, Dyeing (optional) |

|

Chem Film | Aluminum | Clear, Gold | Media Blasting, Tumbling, Anodizing |

|

Powder Coating | Metals, Some Plastics | Wide range (customizable) | Electrostatic application, Curing oven |

|

Texturing | Resins, Plastics, Metals | Natural material color | Laser etching, Chemical etching |

|

Tumbling | Resins, Plastics, Metals | Natural material color | Abrasive media, Vibratory tumblers |

|

Clear Coating | Resins, Plastics, Metals | Clear, Glossy finish | Spray application, UV curing |

|

Laser Engraving | Resins, Plastics, Metals | Natural material color | Laser marking machines |

|

Vacuum Metallization | Plastics, Resins | Chrome, Gold, Silver, etc. | Vacuum chamber, Metal vapor deposition |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Vacuum Casting Supplier Selection Ultimate Guide

Which vacuum casting supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Vacuum Casting FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What is your standard lead time for vacuum casting?

Typically, our standard lead time is 7-10 days with rush rates by request.

What is the typical tolerance you can provide?

Generally, we would expect ±0.05 mm or so tolerance, depending on part geometry and resin type.

What materials can I select for vacuum casting?

Generally, materials used are polyurethane, epoxy resin, silicone rubber, acrylic resin, and urethane elastomers.

Can you match special colors or textures?

Yes, custom color matching and surface finishes like painting and polishing are achievable.

For how long will the silicone molds remain effective?

Rotor set silicone molds will remain effective for about 15-25 castings before quality is compromised.

Can vacuum-cast parts be functional tested?

Vacuum-cast parts can be easily utilized for functional testing and validation before mass production.mass production.

Vacuum Casting Resource

Are You Looking for Vacuum Casting Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.