Your Trusted Partner from Early Prototyping to Final Production

Trusted for consistent-quality prototypes and end-use parts since 2016.

Convert your design into prototype, get your premium injection molded parts more than expected.

Injection Molding Manufacturer from China

Est.2016, Formioo is one of the most reliable rapid prototyping companies, we can turn your designs and ideas into real parts in just a few days.

- 10+ years industrial experience

- 5000 square meters factory area

- 100,000+ unique parts manufactured annually

- 30k+ plastic part projects delivered in the past 10 years

- Supplier for EPSON, BMW, HONDA, HP, Honeywell, etc.

Our Manufacturing Capabilities

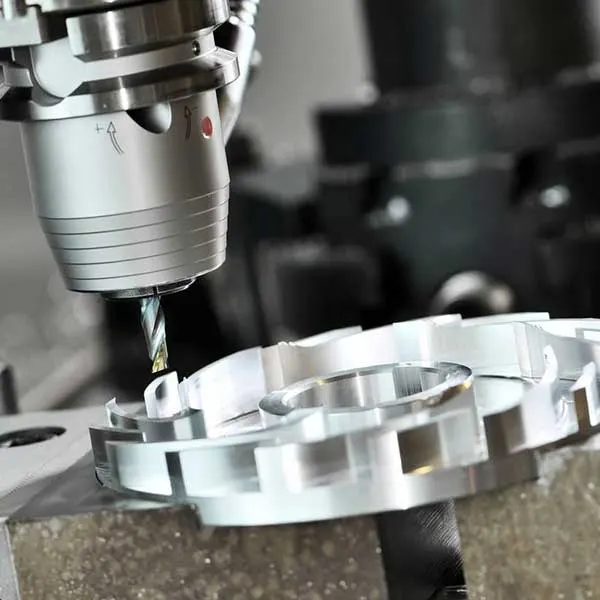

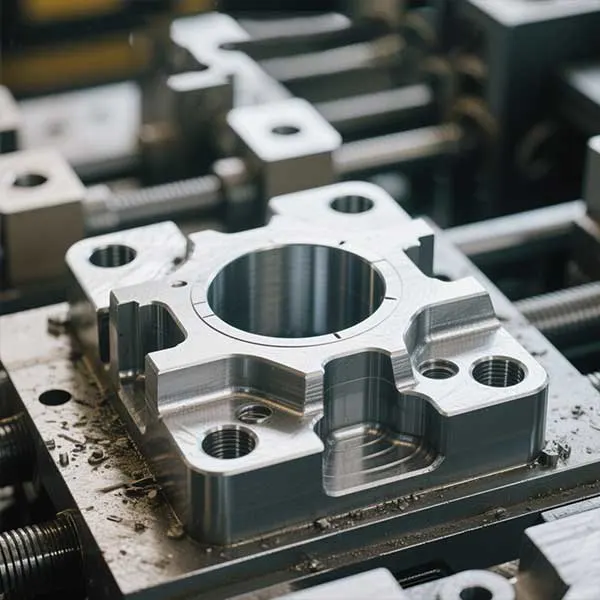

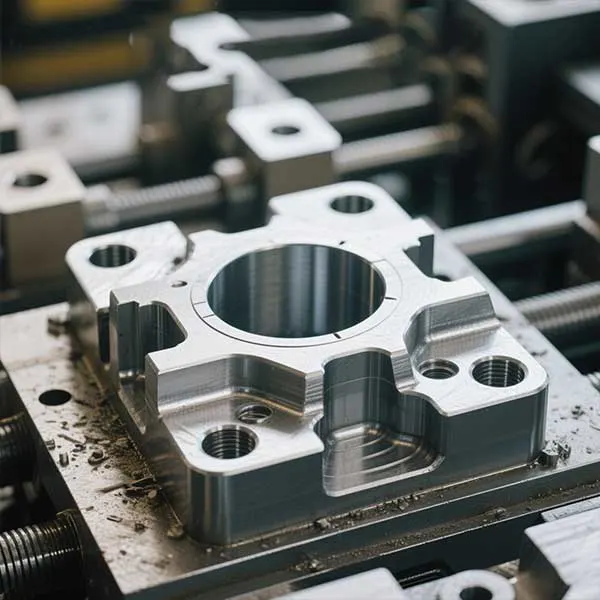

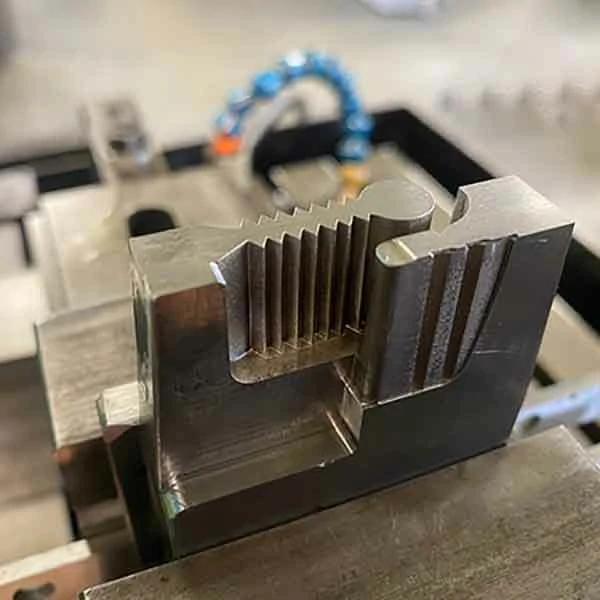

CNC Machining

T1 samples as fast as 10 days with low minimum order quantities.

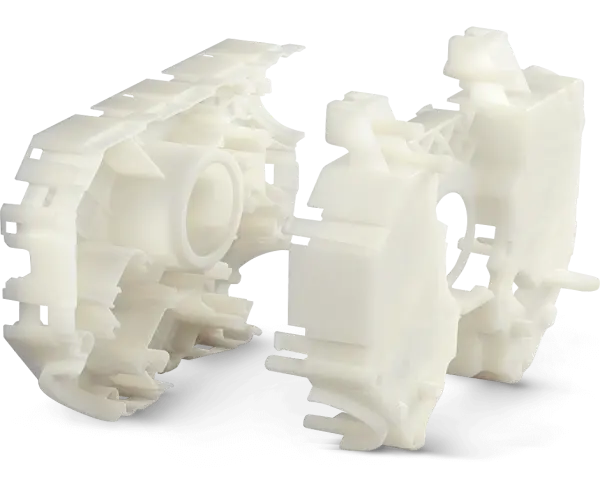

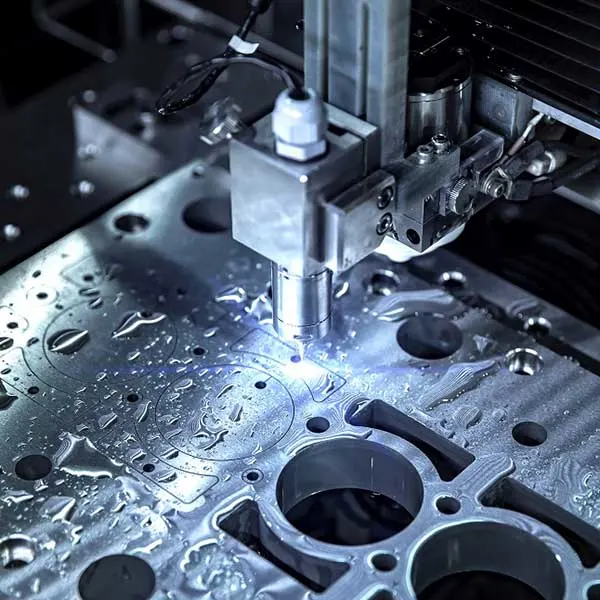

Injection Molding

Tight tolerances and finishing capabilities, as fast as 2 days.

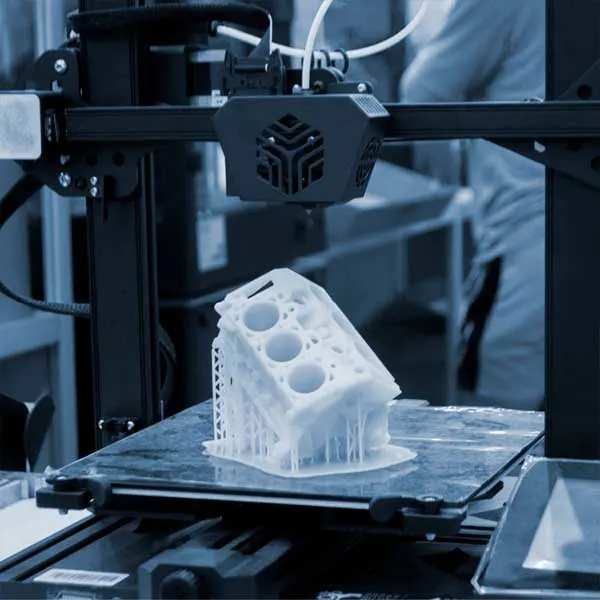

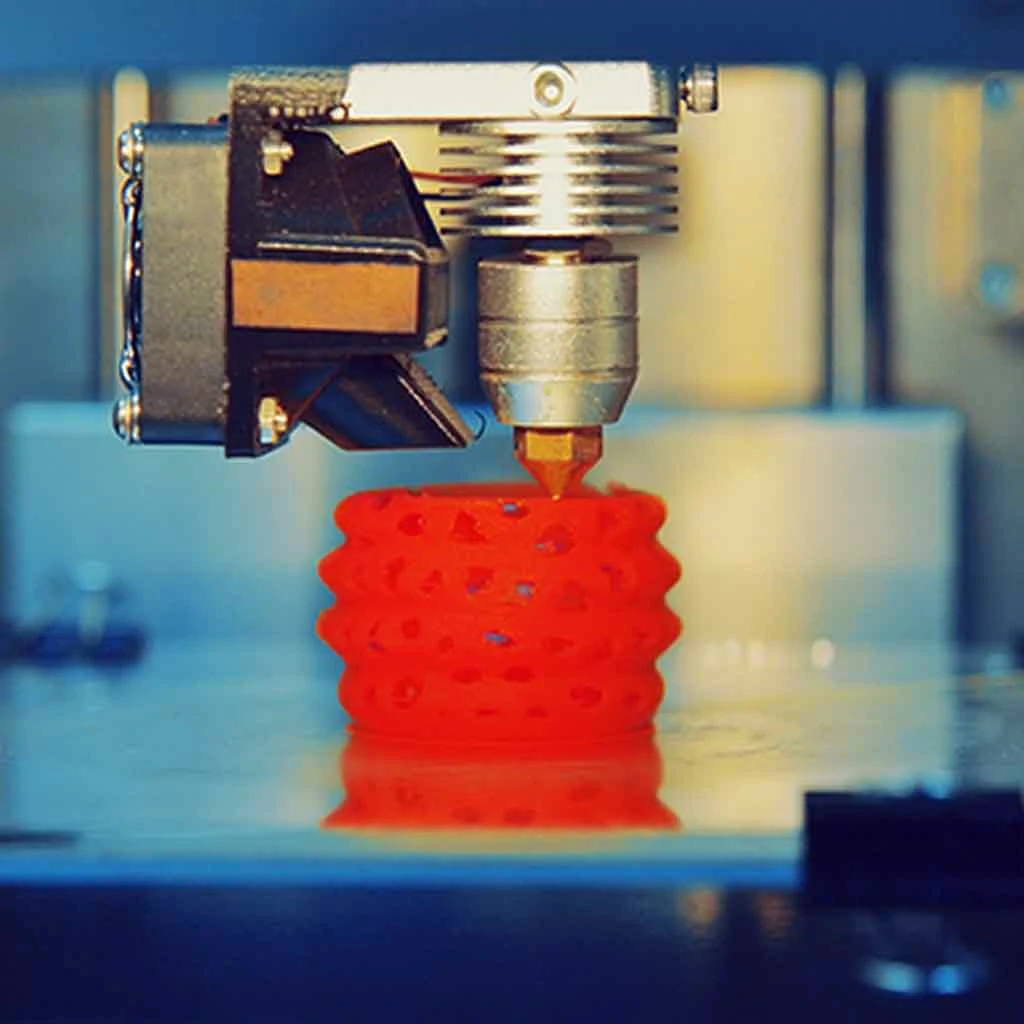

3D Printing

FDM, SLS, SLA, PolyJet, MJF technologies.

Die Casting

Create high quality custom mechanicals with precision and accuracy.

Sheet Metal Fabrication

Experience the versatility & cost efficiency with flexible application options.

Custom Extrusion

Tight tolerances and finishing capabilities, as fast as 2 days.

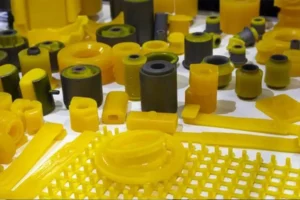

Urethane Casting

Production quality parts without the tooling investment.

Explore Our solutions by industry needs

Get a firsthand look at our fabricated brass valves, pipe fittings, heating system,water system, and much more.

Custom Manufacturing Solutions

Our in-house facilities allow us to get your projects done fast. And thanks to our strong relationship with rapid manufacturing partners, our capacity is not limited.

- 10 trusted rapid manufacturing partners in our manufacturing network

- Our technique was absorbed from Taiwan and Europe

- 30+M Parts manufactured through our network

- 150000+ Hours of monthly machine capacity, on-demand

Contact Us

+86-133 7015 8119

Our Email

info@formioo.com

On-Demand Manufacturing Solutions

Rapid Prototyping

We specialize in fast injection molding for prototypes, with lead times as short as 7–10 working days. Ideal for engineering validation and market testing before mass production.

Low-Volume Manufacturing

Our low-volume production service supports 100 to 5,000 pieces, helping you reduce mold investment while maintaining consistent quality for short-run batches.

Mass Production

For larger orders, we provide stable mold performance with up to 100,000–300,000 shot life, ensuring repeatability, cost-efficiency, and standard ISO quality practices.

Sub-contract offerings

Formioo’s sub-contract services seamlessly integrate with your business, and our skilled team will handle them with precision, ensuring timely delivery and quality.

Production Tooling Service

Our in-house and partner tool shops build steel or aluminum molds with DFM support. Typical mold lead time ranges from 15 to 25 working days, depending on complexity.

Overmolding Service

We support insert molding and 2-shot overmolding for projects requiring dual materials, soft-touch surfaces, or embedded components like metal inserts or PCBs.

Surface Finishing

Available finishing options include light texturing, polishing, painting, pad printing, and laser marking. We ensure aesthetic and functional quality per your requirements.

Assembly Services

We offer basic post-molding assembly like ultrasonic welding, screw fitting, or packaging for small-to-medium runs, helping you receive ready-to-use parts from a single source.

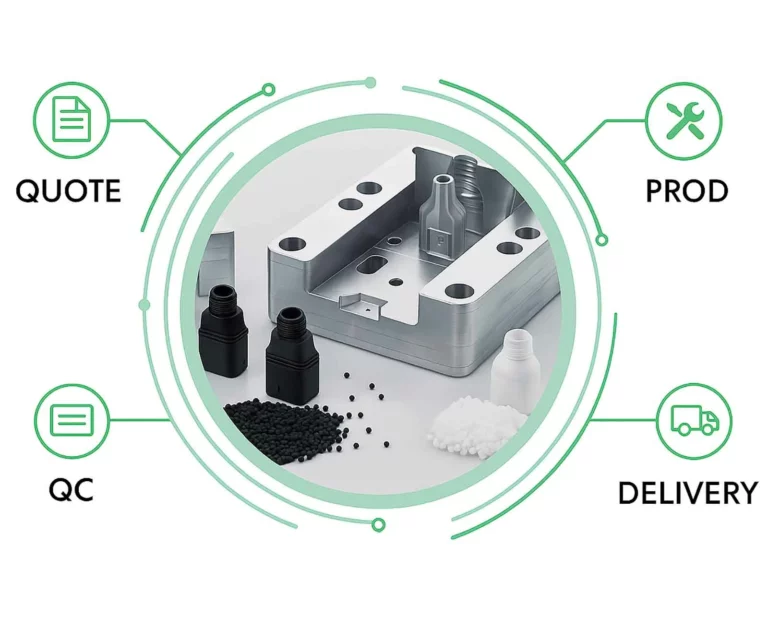

Manufacturing on Demand for the Injection Molding

Ready to turn your design into real parts? Upload your files now and get an instant quote from our expert team.

1. Upload a CAD File

To start, simply select a manufacturing process and upload a 3D CAD file.

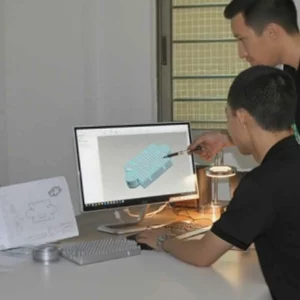

2. Get Quote with DFM

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

3. Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

4. Parts are Shipped!

Our digital manufacturing process allows us to produce parts in as fast as 1 day.

Formioo Solve Your Biggest Sourcing and Manufacturing Challenges

Rich Experience

Having carried out rapid prototyping and rapid manufacturing since 2016, our engineers have built up rich experience. We can handle all types of projects.

Massive Network

Our in-house facilities allow us to get your projects done fast. And thanks to our strong relationship with rapid manufacturing partners, our capacity is not limited.

Expert Engineering Support

We don't just supply a service, but our engineers also provide valuable guidance on manufacturability, material specification, and design optimization to ensure that the production is smooth.

On-Time Delivery Guarantee

We are keen on deadlines. Our seamless workflow and powerful manufacturing relationships guarantee timely delivery of your parts, even on tight timelines.

Formioo Injection Molding Manufacturing FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What are the benefits of working with Formioo?

We provide industrial-grade 3D printing, CNC machining, sheet metal fabrication, and injection molding services to produce parts directly from our customers’ 3D CAD models, minimizing the risk of errors. With proprietary software, we are able to automatically generate tool paths, significantly reducing production time and manufacturing costs.

How do I get a quote?

Send us CAD files (such as STEP format), and tell us the quantity, material, surface finish, color, or other requirements you need, then we will check and evaluate, and give you a suggestion for the part design and quote you.

What CAD type do you accept?

We accept native SolidWorks (.sldprt) and ProE (.prt) files, as well as solid 3D CAD models in IGES (.igs), STEP (.stp), ACIS (.sat), and Parasolid (.x_t or .x_b) formats. .stl files are also supported, but two-dimensional (2D) drawings are not accepted.

Do you provide First Article Inspection (FAI) services?

Yes, we provide First Article Inspection (FAI) services for machined and molded parts.

Does Formioo offer finishing options and secondary operations?

Yes, our services include a variety of enhanced finishing and secondary processing options, including injection molding, CNC machining, 3D printing, and sheet metal processing.

Who owns the mold?

Our customer! Mold belongs to our customer property, it will only be used to produce plastic parts for you, and handled by you.

Can the mold be modified after the first run?

Yes, if you are not satisfied with the T1 samples and want to change some structures, please provide a newly updated CAD file. We will then recheck it and inform you of any necessary mold modification costs.

Can different parts be made in one mold?

Yes, it is called a family mold. If these parts are the same color, material, it is a good way to reduce the mold cost and make these parts in one mold.

What Our Clients Say about Us

Start Your Injection Molding Journey With Formioo

Let’s build something great, together.