Custom Over Molding Services

Formioo provides high-quality custom overmolding services for prototypes and on-demand production parts. We can produce molds in as little as 2 weeks.

- High-precision over molding with tolerances as tight as ±0.01 mm

- 50+ Certified Materials & 15+ Surface Finishing Options

- More than ten years of professional overmolding manufacturing experience

- Rapid DFM review with wall thickness tips within 48 hours

Over Molding Small Batch Production Manufacturer from China

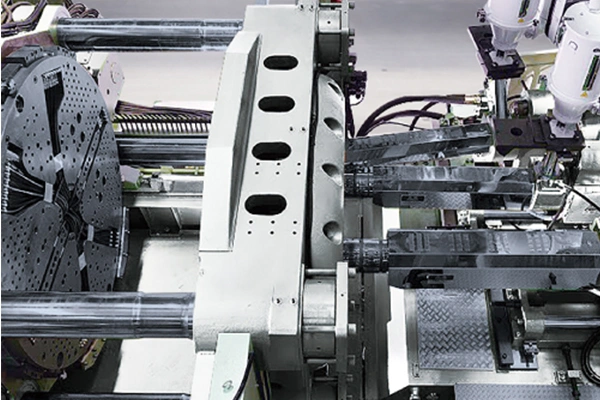

Formioo is a dedicated over molding manufacturer in China, focused on producing multi-material plastic and metal components with speed and precision. With in-house mold making, rapid tooling, and advanced injection equipment, we support quick prototyping and low-to-mid volume production with flexible turnaround times to meet fast-changing customer needs.

Our over molding services allow seamless bonding of two or more materials—such as soft TPE over rigid ABS, or plastic over metal inserts, enabling enhanced ergonomics, better sealing, electrical insulation, and improved product aesthetics. We offer full DFM (Design for Manufacturability) feedback and insert alignment optimization to help customers solve challenges like poor adhesion, misalignment, and material incompatibility. Whether you’re developing a handheld device, connector, or medical component, our process ensures consistent quality and reliable performance.

Backed by a responsive engineering team and a growing production capacity, Formioo supplies over molded parts to clients in the automotive, electronics, consumer product, and medical accessory sectors. Whether you’re developing prototypes or preparing for scaled manufacturing, we’re here to deliver dependable quality with a flexible, customer-first approach.

Our Over Molding Services

Formioo offers a full range of over molding technologies, including Thermoplastic Elastomer (TPE) Over Molding, Insert Molding, and Two-Shot Molding. These processes enable us to combine rigid substrates, such as ABS, PC, Nylon, or even metal inserts, with softer materials like TPE, TPU, or silicone, enhancing grip, vibration resistance, sealing, and product aesthetics. We work with a wide selection of engineering-grade plastics and elastomers to support functional and decorative part designs for various applications.

To ensure the best performance and appearance, we provide a variety of surface finishing options for over molded parts, including texturing, polishing, soft-touch coating, laser etching, and pad printing. Our molding processes typically achieve tolerances of ±0.1 mm, and can reach as tight as ±0.01 mm for critical dimensions, depending on part geometry and material compatibility. All parts undergo thorough visual and dimensional inspection to ensure clean transitions between materials, strong adhesion, and reliable repeatability across production runs.

Injects two materials sequentially in one cycle.

Encases pre-placed inserts with molten material.

Combines materials simultaneously for layered parts.

Bonds soft TPE to rigid substrates.

Over Molding Capabilities

Material Compatibility

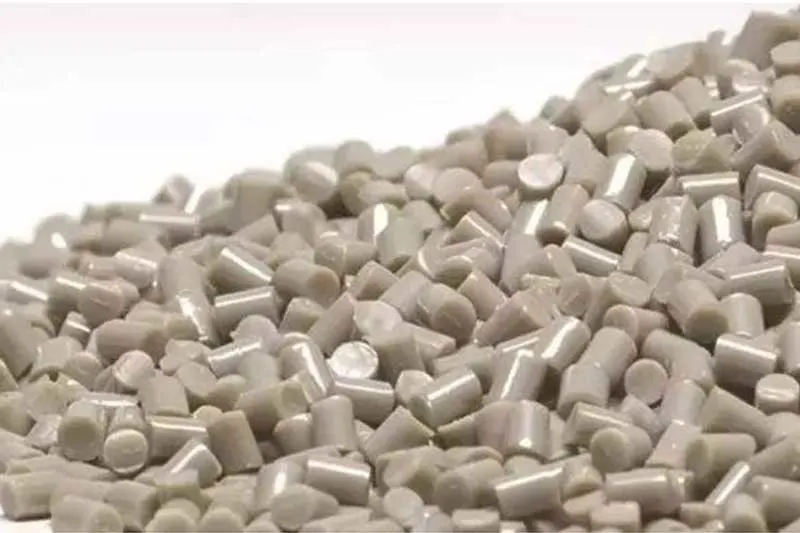

Our capable of molding combinations of materials such as TPE, silicone, rubber, ABS, PC, and other engineering plastics, meeting various industrial and custom production needs.

Printing Accuracy

Our standard tolerance is controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Maximum Build Size

Our maximum molding size is up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Surface Finishing Options

We support polishing, painting, sandblasting, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard over molding lead time is 5-10 days, with rush service available for quick-turn programs.

Massive Network

We work with trusted injection molding suppliers.

This is Modal Title

[contact-form-7 id="852" title="Contact Us"]

Explore Over Molded Products We Manufactured

Our complete over molding service will accompany your over molding project from the prototype construction to the end parts manufacturing.

Over Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Overmolding Parts | +/- 0.3 mm to +/- 0.6 mm |

| Precision Overmolding Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Overmolding Parts | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Over Molding Materials

PP

Polypropylene (PP) finds extensive application for over molding with high chemical resistance, fatigue endurance, and good impact resistance. Its excellent adhesion characteristics enable it to create dual-material parts, e.g., soft-touch handles on a hard substrate or molded-in seals in automotive applications. PP’s versatility is observed through its uses in consumer electronics, household appliances, and industrial products. Elastomer and other polymer compatibility allow the product a long life together with design versatility. Low density also allows cost saving in bulk production without sacrificing high performance in different conditions.

- Mill Lead Time: 3 days

- Color: Natural, with options for vibrant dyes

PE

Polypropylene (PP) finds extensive application in over molding for reasons such as high chemical resistance, fatigue strength, and better impact strength. Its favorable adhesion characteristics qualify it for the construction of dual-material parts, such as soft-touch grips over hard backing or molded-in gaskets in automotive parts. The multifunctionality of PP is seen through its uses in consumer electronics, home appliances, and industrial products. Miscibilities such as elastomer and other polymers provide the product’s toughness as well as design versatility. Low density also aids in cost-cutting in mass production without any loss of high performance under diversified conditions.

- Mill Lead Time: 2 days

- Color: Translucent white, customizable shades

PS

Polystyrene (PS) offers a smooth surface finish and hardness, thus is a better material for over molding. Moldability and thermal stability of PS offer optimum bonding when mixed with soft elastomers for ergonomic grip or for decorative overlays. PS is employed heavily in consumer goods, including covers for remote controls, appliance housings, and parts utilized in packaging that require a clean, crisp appearance. The versatility of the material in working with various finishes and hues only increases the demand for designing aesthetically appealing parts that function best with repeated stress and the elements.

- Mill Lead Time: 2-3 days

- Color: Glossy white, available in custom tones

ABS

ABS (Acrylonitrile Butadiene Styrene) is an emulsion-synthesized commodity thermoplastic polymer that enjoys acceptable chemical corrosive resistance. Because of this, it is commonly used in products such as car parts, children’s toys, and electric enclosures.

ABS is easy to machine and possesses a quite low melting point, making it easy to mold and form. It is highly resistant to impact, thus ideal for products that are subjected to high stress or pressure. These special characteristics render ABS extensively applied across the world in many industries.

Common applications: Enclosures

PC

Polycarbonate (PC) stands out in over molding because it has high clarity, enhanced impact strength, and excellent heat resistance. Its elastomeric overmold compatibility also makes it ideal to use and create products such as protective coverings, optics parts, and high-strength electronic enclosures. The flame retardancy and dimensional stability of PC also make it a strong contender in automotive lighting and secure enclosures. Over molding with PC offers a pure, high-quality finish that can meet demanding performance specifications while the flexibility in design and customization toward consumer electronics and industrial applications is available.

- Mill Lead Time: 3-4 days

- Color: Crystal clear, with tinted options

PA

Polyamide (PA), or Nylon, is used in over molding because it exhibits excellent mechanical properties, impact resistance, and stability at temperature. It can bond strongly to softer substrates and hence, best to be used in end-use applications like heavy-duty gear housings, automotive connectors, and heavy-duty consumer product components. Nylon over molding can provide parts with high strength and wear resistance requirements, like sealed bearings and covers. Due to its toughness as well as abrasion-resistance characteristics, it is a perfect part for repeated stress and friction parts ensuring stable performance in hostile conditions.

- Mill Lead Time: 4 days

- Color: Natural off-white with dyeing options

POM

Polyoxymethylene (POM), or acetal, is well known for its superior stiffness, low friction, and high dimensional stability. Because of these characteristics, it becomes one of the finest fit possibilities for precision- and durability-driven over molding applications. In consumer electronics and transportation, POM is used to manufacture over molded gears, pump components, and switch housings where its superior adhesion with elastomer layers provides enhanced shock absorption as well as feel in ergonomic terms. Its chemical and abrasion resistance gives lasting performance, even with repeated stress. The material is specifically worthy of consideration for its uses that include mechanical integrity and demand smooth, pleasant surfaces.

- Mill Lead Time: 4 days

- Color: Natural, with custom pigmentation options

PEEK

PEEK is a thermoplastic with high performance that is valued for its superior strength, chemical resistance, and high-temperature ability. In over molding, PEEK is utilized where it is necessary to have high-performance, such as aerospace components, medical devices of high quality, and high-performance automotive components. Its ability to be bonded with elastomeric layers enables the creation of multi-functional components that combine stiffness with compliance for the production of seals and shock absorbers. Despite its high cost, PEEK offers high performance in critical components that must have durability and precision under harsh environments. Its enhanced mechanical properties make it non-replaceable in applications where failure is not acceptable.

- Mill Lead Time: 7 days

- Color: Natural amber, with specialty coatings

PEI

Ultem (PEI) is an advanced-temperature plastic with exceptional flame resistance, dimensional stability, and good mechanical properties. Its use in over molding is optimally suitable for the production of components that require both strength and aesthetics, such as high-end electronic enclosures, medical device covers, and auto parts. Ultem’s elastomer overmold compatibility allows for the introduction of soft-touch surfaces with rigid structural cores. The material performs very well when high heat resistance and chemical stability are needed. The resulting over molded parts are durable and also very attractive, making Ultem a best-seller in high-end consumer and industrial products.

- Mill Lead Time: 7 days

- Color: Natural amber with options for bright, engineered finishes

LCP

Liquid Crystal Polymer (LCP) is unique high-performance plastic with greater chemical resistance, high strength, and low moisture absorption, making it highly suitable for over molding. Its anisotropy is beneficial in providing good dimensional stability and precision, suitable for intricate parts such as connector housings, micro-mechanical parts, and high-frequency electronics. LCP over molding produces parts that are light yet tough and features seals and ergonomics through its compatibility with elastomeric films. Its excellent performance under extreme conditions has seen extensive use in the automotive and electronics industries, with high-stress application reliability promised.

- Mill Lead Time: 6 days

- Color: Natural translucent, with customizable hues

PI

Polyimide (PI) is characterized by its enhanced thermal stability in addition to its better mechanical performance, making it the best among more than molding under extreme conditions. PI can be found in aerospace and electronics, offering reliable insulation and strength at high temperatures and with sustained stress. PI over molding appears in advanced circuit boards, high-temp seals, and high-precision mechanical parts. Its resilience in tough environments is what establishes it as the best to be used in performance and durability-based applications. Its strength combined with its versatility ensures that PI-based products are held to high expectations in high-performance industries.

- Mill Lead Time: 8 days

- Color: Deep brown, with high-gloss finish

Finishing Options for Over Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Smooth Finish | Various thermoplastics, elastomers | Various thermoplastics, elastomers | Mold polishing, Hand-finishing techniques |

|

Matte Finish | ABS, Polycarbonate, Polypropylene | Matte Black, Matte White | Sandblasting, Matte coating processes |

|

Glossy Finish | Acrylic, ABS, PC | High-gloss, Transparent | Mold polishing, Gloss coating application |

|

Textured Finish | ABS, Polypropylene, Polycarbonate | Custom color palette | Texturing molds, Embossing, Laser etching |

|

Soft Touch Finish | Elastomers, TPE, TPU | Soft Neutral tones | Co-extrusion, Soft-touch over molding |

|

Anti-Slip Finish | Polypropylene, ABS, Nylon | Standard Grey, Custom hues | Embossing, Knurling, Laser texturing |

|

Metalized Finish | Polycarbonate, ABS, Nylon | Metallic Silver, Gold, Bronze | Vacuum metallization, PVD, Sputtering |

|

UV Coating | ABS, Polycarbonate, Acrylic | UV Clear, Tinted | UV curing, Spraying, Dipping |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Over Molding Supplier Selection Ultimate Guide

Which over molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Over Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What materials can you use for Over Molding?ormioo?

We are able to utilize an immense array of thermoplastics, elastomers, and silicones to suit your application needs.

What techniques do you utilize in establishing high strength adhesion between materials?

Our technique entails material compatibility tests and surface treatments to get a durable bond.

What’s the typical lead time for Over Molding projects?

Typically 4-6 weeks, but we can expedite for critical programs. Inform us regarding your schedule.

Do you offer design-for-manufacturability (DFM) services?

Yes, our engineers will redesign your design from cost, performance, and manufacturability perspectives.

Can you produce Over Molding parts for medical or consumer applications?

Definitely! We’re experienced in meeting strict standards for medical, consumer, and industrial sectors.

Do you provide secondary services like trimming or assembly?

Yes, we provide full-service solutions including trimming, assembly, and quality inspection.

Over Molding Resource

Are You Looking for Over Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.