Custom Medical Prototyping & Manufacturing

Formioo provides high-precision medical plastic injection molding services using certified biocompatible materials, ensuring cleanroom manufacturing, tight tolerances.

- Materials that are biocompatible, non-toxic, or sterilizable

- Tight tolerances for critical parts and assemblies

- Quality control via on-machine inspection and/or CMM

- More than 10 years of experience in producing medical parts

- 24/7 engineering support

One Stop Solution Provider for Medical Plastic Injection Molding from China

Formioo is a professional medical injection molding manufacturer in China, specializing in rapid prototyping and production of medical plastic components. Equipped with certified facilities, in-house mold making, and cleanroom molding capabilities, we turn your medical-grade designs into high-precision prototypes and end-use parts in as fast as 7 days.

We offer full DFM analysis, mold flow simulation, and material selection support to help clients avoid costly design issues, accelerate regulatory approval, and ensure biocompatibility. Whether you’re developing diagnostic devices, wearable healthcare products, or surgical instrument components, our injection molding solutions deliver tight tolerances, consistent quality, and traceable documentation.

With over 10 years of experience, Formioo has produced hundreds of thousands of medical plastic parts annually for global customers ranging from medtech startups to established OEMs. Our stable production system and strict quality control processes make us a trusted partner throughout the entire medical product development cycle, from initial prototype to volume manufacturing.

What kind of medical plastic injection molding parts can we make?

Formioo specializes in manufacturing a wide variety of custom medical plastic components through precision injection molding. We produce parts such as housings for diagnostic devices, enclosures for wearable monitors, surgical handles, microfluidic chips, catheter components, and drug delivery casings. To meet the strict requirements of the medical industry, we work with certified materials including medical-grade PP, PC, ABS, PEEK, PEI (Ultem), and TPE, ensuring biocompatibility, chemical resistance, and sterilization compatibility.

Our injection molding services are supported by advanced mold-making, overmolding, insert molding, and multi-cavity tooling technologies. We also offer post-molding services such as ultrasonic welding, pad printing, and laser marking for traceability and branding. With high-precision tooling and molding equipment, we can achieve tight tolerances up to ±0.05 mm and consistent part quality across batches. Cleanroom molding, automated dimensional inspection (CMM), and documentation for FDA/ISO compliance are available to support critical healthcare applications.

- Surgical instrument housings

- Diagnostic device enclosures

- Syringe barrels

- Infusion pump casings

- Catheter connectors

- Drug delivery module components

- Implantable device housings

- Medical tubing connectors

- Ventilator casings

- Laboratory equipment parts

- Biocompatible clips and fasteners

- Sterilizable packaging components

- Medical circuit board enclosures

- Surgical tool grips

- Emergency medical device housings

- control module enclosures

- Blood collection tube connectors

- Fluid reservoir units

- Dental instrument housings

- Biochip casings

- Dialysis machine components

- Endoscope housings

- Oxygen mask casings

- Disposable lancet housings

Medical Plastic Injection Molding Capabilities

Material Compatibility

We provide medical-grade plastics such as PEEK, PC, ABS, PP, PE, and silicone that meet high standards of biocompatibility and sterilization.

Printing Accuracy

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for medical devices and components.

Maximum Build Size

Our maximum part size is up to 500mm × 500mm × 300mm, suitable for small to medium-sized medical parts.

Surface Finishing Options

We support polishing, texturing, ultrasonic welding, laser etching, and more for enhanced functionality and aesthetics.

Delivery Time

Our standard lead time is 7-15 days, with expedited service for medical work requiring urgency.

Massive Network

We work with trusted injection molding suppliers.

Explore Our Latest Medical Plastic Injection Molding Products

Explore our precision-engineered medical plastic parts and see the quality for yourself. From prototyping to mass production, our high-performance components meet the strictest medical industry standards.

Medical Plastic Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Medical Plastic Parts | +/- 0.1 mm to +/- 0.3 mm |

| Precision Medical Parts | +/- 0.05 mm to +/- 0.1 mm |

| Complex Medical Parts | +/- 0.1 mm to +/- 0.3 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Medical Plastic Injection Molding Materials

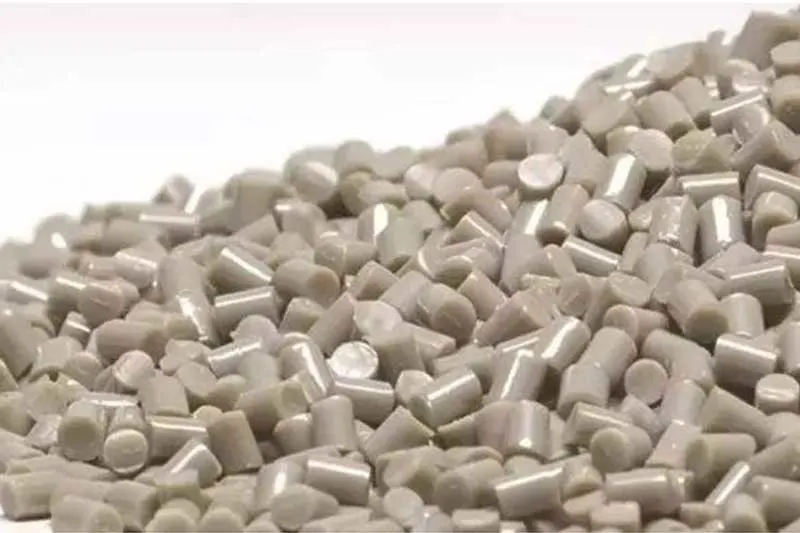

pp

Polypropylene is very much in demand in medical injection molding because it has very good chemical resistance, toughness, and compatibility with the majority of methods for sterilization. It is also used to make syringes, vials, and specimen bottles that should be autoclaved. For instance, PP is commonly used to make medical syringes and specimen cups because they are chemical-resistant and durable.

- Mill Lead Time: Up to 3 weeks

- Color: Natural, white, black

PE

Polyethylene is most suitable for plastic injection molding in the medical industry due to its superior chemical resistance, flexibility, and biocompatibility. It is particularly well-suited to produce products like tubing, bottles, and containers which need to be able to survive sterilization procedures. PE finds widespread application in the medical industry in medical packaging, surgical drapes, and blood bags. One of the best applications of PE is for the production of blood storage bags, which have to be flexible and resistant to corrosive chemicals.

- Mill Lead Time: Up to 3 weeks

- Color: Natural, white, black

ABS

Acrylonitrile Butadiene Styrene (ABS) is a generic-purpose thermoplastic resin that is produced by emulsion. It is chemically resistant to corrosion and is widely used in motor vehicle parts, toys, and electronic cases.

It is easy to machine and possesses a relatively low melting point that can easily be molded and formed. Its resistance to impact is high, and therefore suitable for applications that incur high stress or impact. These are the unique properties of ABS and thus find extensive applications on the global platform in various industries.

Common applications: Enclosures

PC

Polycarbonate is also used in medical plastic injection molding due to its shock resistance, transparency, and gamma radiation sterilization compatibility. Polycarbonate is used for the manufacture of handles of surgical instruments, blood oxygenators, and similar components of medical devices. For example, PC is used extensively for surgical instrument applications requiring ruggedness and transparency, e.g., endoscopes.

- Mill Lead Time: Up to 3 weeks

- Color: Clear, transparent

PSU

Polysulfone’s mechanical properties and heat resistance make it a suitable material for medical plastic injection molding. Polysulfone is commonly used for components that must be sterilized over and over again. PSU, for example, is commonly used for components used in dialysis machines and handle components of surgical tools due to heat resistance.

- Mill Lead Time: Up to 4 weeks

- Color: Transparent amber

PET

PET finds extensive usage for plastic injection molding for medical purposes due to its favorable strength, chemical resistance, and transparency. It finds special application in products requiring transparent packaging or hard barriers. For example, PET is used in the production of diagnostic test kits and medical packages where clarity and hardness are crucial.

- Mill Lead Time: Up to 3 weeks

- Color: Clear, transparent

PEEK

PEEK is also found to be extremely significant in medical plastic injection molding due to high mechanical properties, chemical resistance, and biocompatibility. It is used where high performance is required, such as sterilization compatibility, such as surgical devices and implantable medical devices. For example, PEEK is extensively utilized in spinal implants due to high strength and its ability to bear severe medical conditions.

- Mill Lead Time: Up to 4 weeks

- Color: Natural (tan), black

TPE

Thermoplastic Elastomers retain the rubber’s flexibility and also offer the advantage of easy processing of plastics and are thus best for soft-touch parts. TPE is also commonly used in medical devices required to be flexible, such as syringe plunger seals. TPE finds its application in flexible grips and seals in medical devices, where comfort and softness are a requirement.

- Mill Lead Time: Up to 3 weeks

- Color: Various, depending on requirements

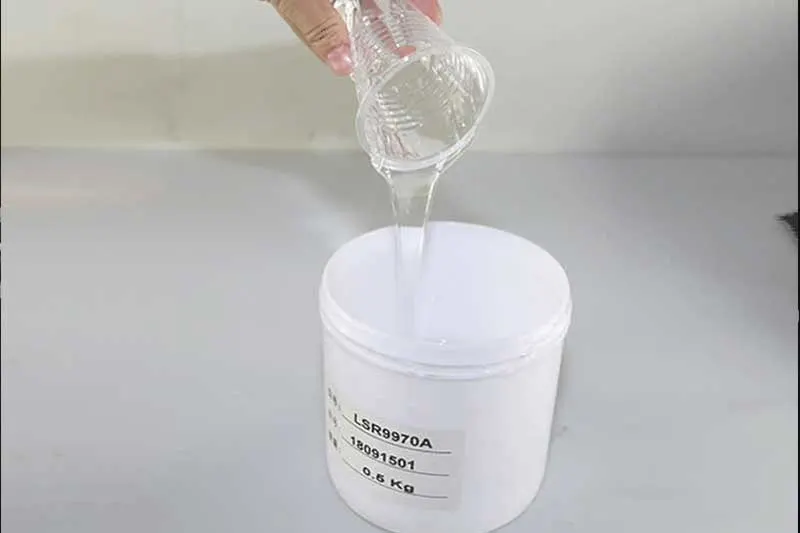

LSR

Flexible character, biocompatibility, and thermal stability of Liquid Silicone Rubber make it a suitable candidate for medical plastic injection molding. It is widely applied in the production of products required to be soft but resilient, such as gaskets and seals. For example, LSR is commonly applied in the production of baby care products, such as pacifiers, because of its soft character and high safety levels.

- Mill Lead Time: Up to 4 weeks

- Color: Translucent, can be pigmented

Finishing Options for Medical Plastic Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum, Stainless Steel | Clear, Gold | Media Blasting, Tumbling, Type II Anodizing, Type III Anodizing with PTFE |

|

Powder Coating | Medical-grade Plastics, Aluminum | Wide range (depending on powder) | Electrostatic Spray, Curing Oven |

|

Anodizing | Aluminum | Clear, Black, Custom | Electrolytic Process |

|

Polishing | Medical Plastics, Stainless Steel | Glossy, Smooth | Polishing Wheels, Buffing Compounds |

|

Electroplating | Stainless Steel, Plastic | Silver, Gold, Chrome, etc. | Electrolytic Process |

|

Laser Etching/Marking | Medical Plastics, Stainless Steel | Natural, Black | Laser Machines |

|

Vibratory Finishing | Medical Plastics, Aluminum, Stainless Steel | Matte, Metallic | Vibratory Tumblers |

|

Brushing | Stainless Steel, Aluminum | Natural metallic finish | Abrasive Brushes, Mechanical Buffing |

|

Surface Sealing | Medical Plastics, Aluminum | Clear, Glossy | Surface Sealing Coating |

|

UV Coating | Medical Plastics | Clear, Glossy | UV Curing Lamps, Coating Equipment |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Medical Injection Molding Supplier Selection Ultimate Guide

Which medical plastic injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Medical Plastic Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Can you produce custom medical components?hat are the benefits of working with Formioo?

Our embedded manufacturers use durable plastics like ABS, PP, PC, PA (Nylon), and POM with heat resistance and durability to utilize in the automotive industry.

Is small-batch prototyping feasible?

Yes. Our vendors offer quick prototyping to allow you to test and validate designs before manufacturing at full capacity.

How much time does production take?

Typical lead times are 10-15 days with priority medical applications available to expedite service.

Are parts biocompatible and can they be sterilized?

Yes, our manufacturers use materials and processes to ISO 10993 standards of sterilization and biocompatibility.

Do you produce parts with complex geometries?

Yes, there are some advanced molding techniques through which complex and intricate medical components can be produced.

How do you control quality?

Rigorous quality checks, including measurements for dimensions and material testing, are conducted at every stage of production.

Medical Plastic Injection Molding Resource

Are You Looking for medical plastic injection molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.