Medical Plastic Injection Molding Services From China

Looking for a reliable Medical Plastic Injection Molding partner? As a professional digital supplier, we can help. Get your medical plastic parts more easily and at a better price.

- Extensive Digital Manufacturing Expertise with a strong supply network

- High-precision injection molding with tolerances as tight as ±0.05 mm

- 50+ Certified Medical-grade Materials & 15+ Surface Finishing Options

- Cost-effective solutions for both prototyping and mass production

- ISO 13485 Certified, ensuring medical industry quality standards

Medical Plastic Injection Molding Small Batch Production

At Formioo, we specialize in medical plastic injection molding, providing cost-effective, reliable, and scalable manufacturing solutions for the medical industry. Whether you need rapid prototyping or mass production, we can match you with the most advanced injection molding technology to ensure each part meets strict medical standards.

With a trusted network of 200+ suppliers, we offer a wide range of capabilities, including multi-cavity molds, overmolding, and insert molding, supporting everything from small batches to high-volume production. Our ISO 13485-certified quality system ensures precision and consistency across 50+ medical-grade materials and 15+ finishing options.

As one of the leading digital injection molding service providers in China, we are committed to delivering high-performance, medical-compliant parts with fast turnaround times. All of our custom-manufactured components are competitively priced without compromising on quality.

What kind of medical plastic injection molding parts can we make?

Formioo specializes in high-precision Medical Plastic Injection Molding, offering a diverse range of products for healthcare applications. Our portfolio includes surgical instrument housings, diagnostic equipment enclosures, fluid connectors, and custom disposable components. We produce sterilizable casings, biocompatible clips, precision fittings, and ergonomic handles designed for medical use. With advanced injection molding technology and strict quality controls, our products meet international regulatory standards for safety and performance, ensuring reliable and effective solutions for modern medical devices.

- Surgical instrument housings

- Diagnostic device enclosures

- Syringe barrels

- Infusion pump casings

- Catheter connectors

- Drug delivery module components

- Implantable device housings

- Medical tubing connectors

- Ventilator casings

- Laboratory equipment parts

- Biocompatible clips and fasteners

- Sterilizable packaging components

- Medical circuit board enclosures

- Surgical tool grips

- Emergency medical device housings

- control module enclosures

- Blood collection tube connectors

- Fluid reservoir units

- Dental instrument housings

- Biochip casings

- Dialysis machine components

- Endoscope housings

- Oxygen mask casings

- Disposable lancet housings

Medical Plastic Injection Molding Capabilities

Material Compatibility

We support medical-grade plastics such as PEEK, PC, ABS, PP, PE, and silicone, meeting strict biocompatibility and sterilization requirements.

Printing Accuracy

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for medical devices and components.

Maximum Build Size

Our maximum part size is up to 500mm × 500mm × 300mm, suitable for small to medium-sized medical parts.

Surface Finishing Options

We support polishing, texturing, ultrasonic welding, laser etching, and more for enhanced functionality and aesthetics.

Delivery Time

Our standard lead time is 10-15 days, with expedited service available for urgent medical projects.

This is Modal Title

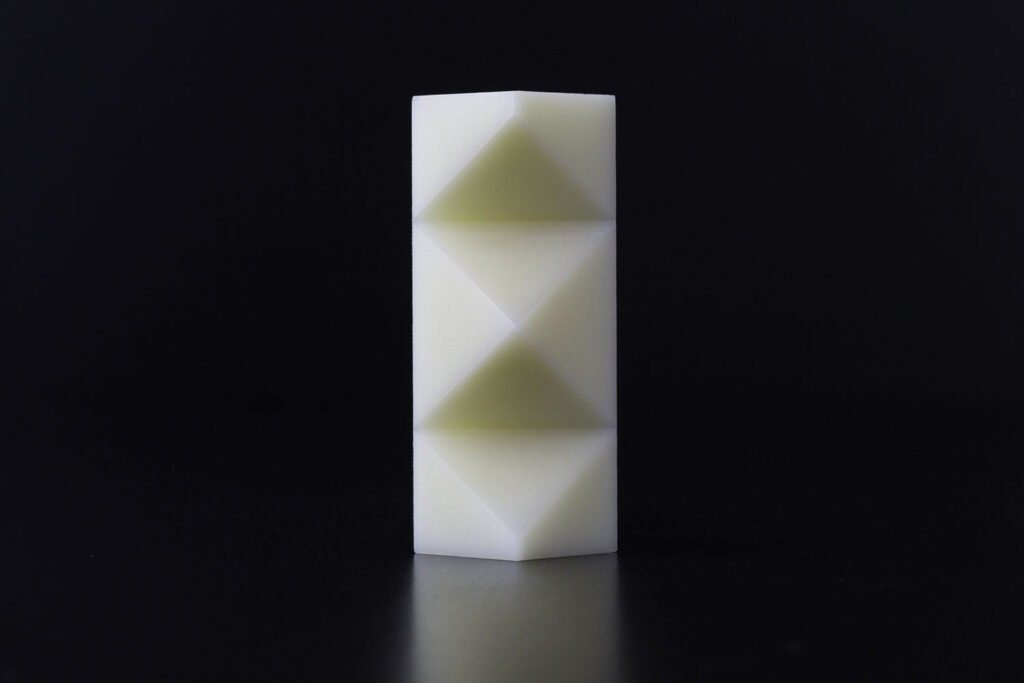

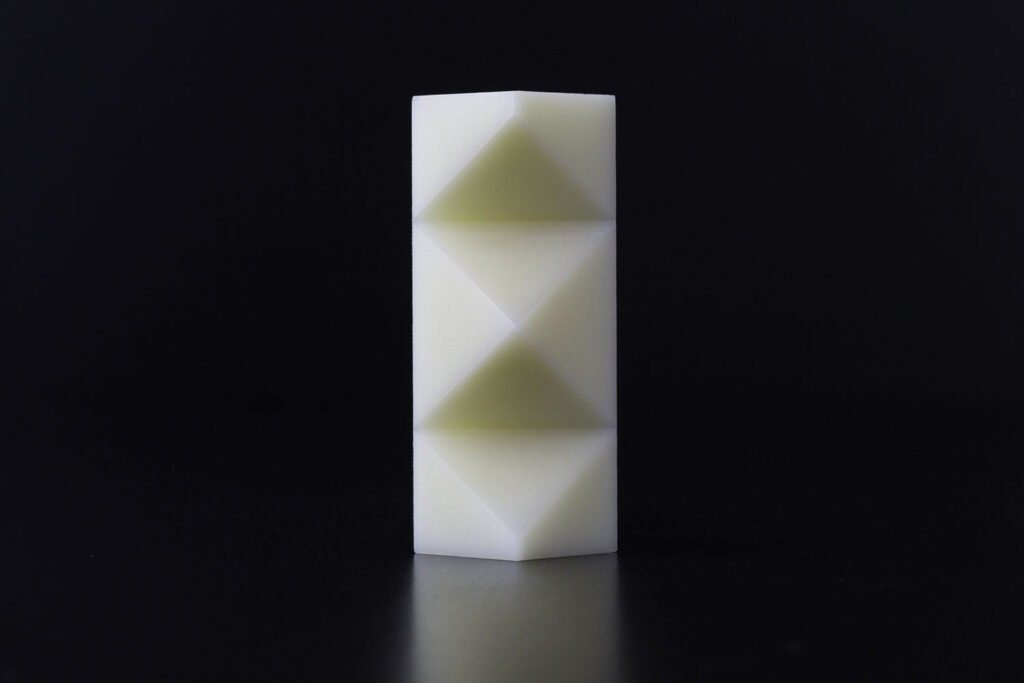

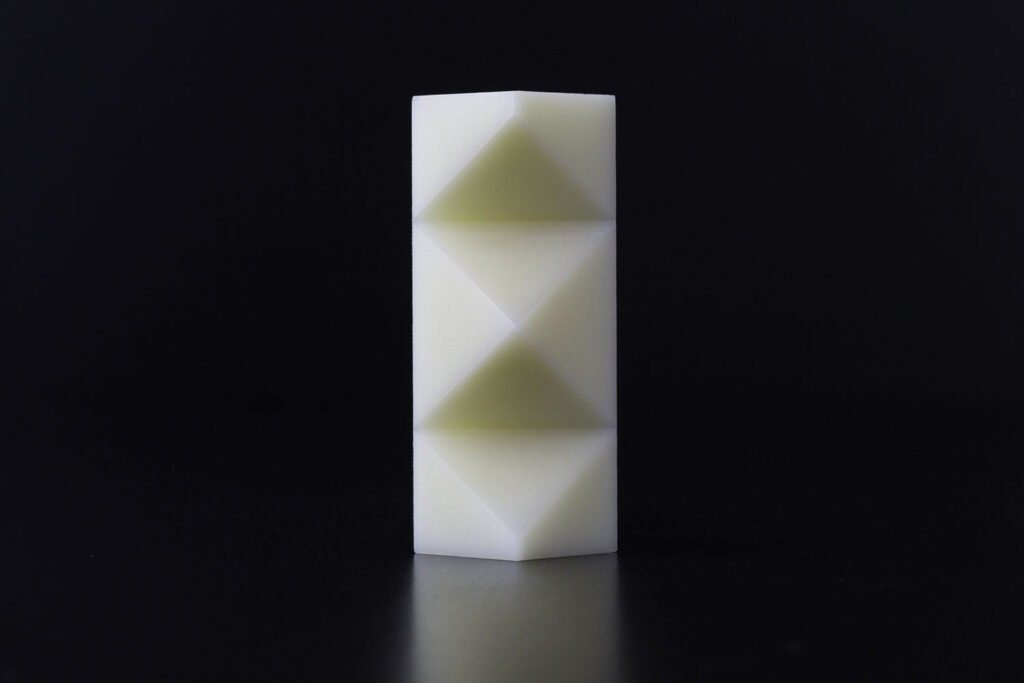

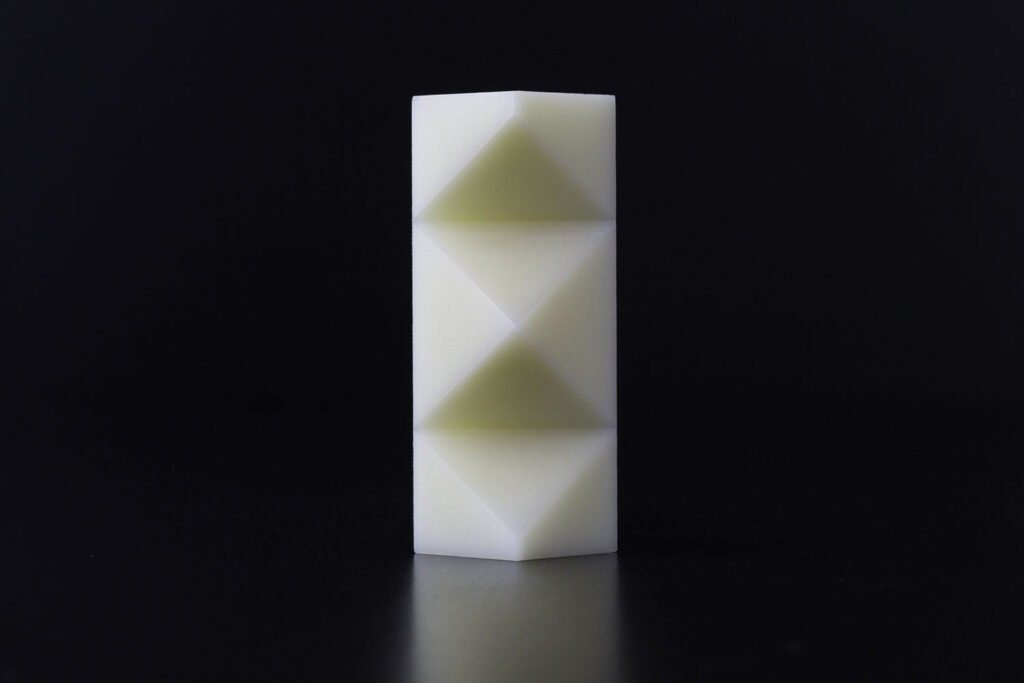

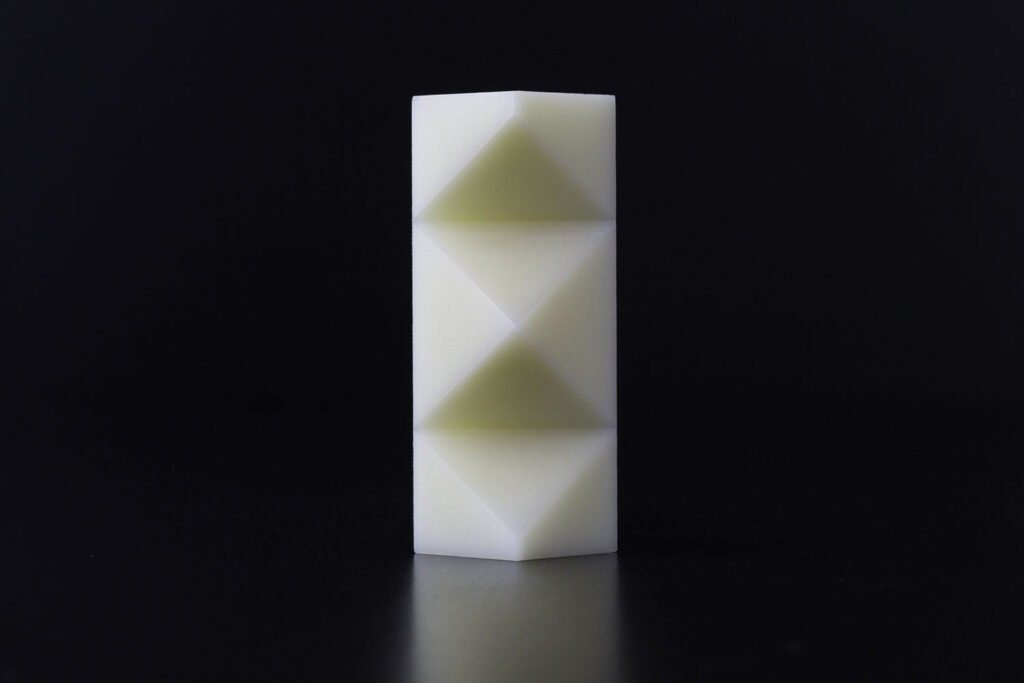

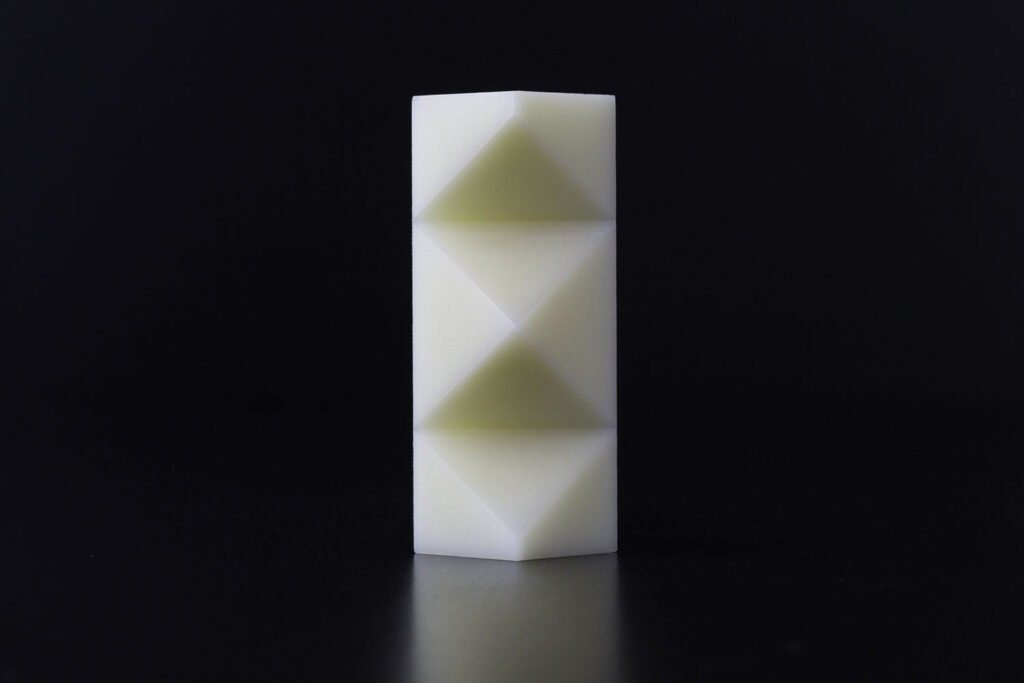

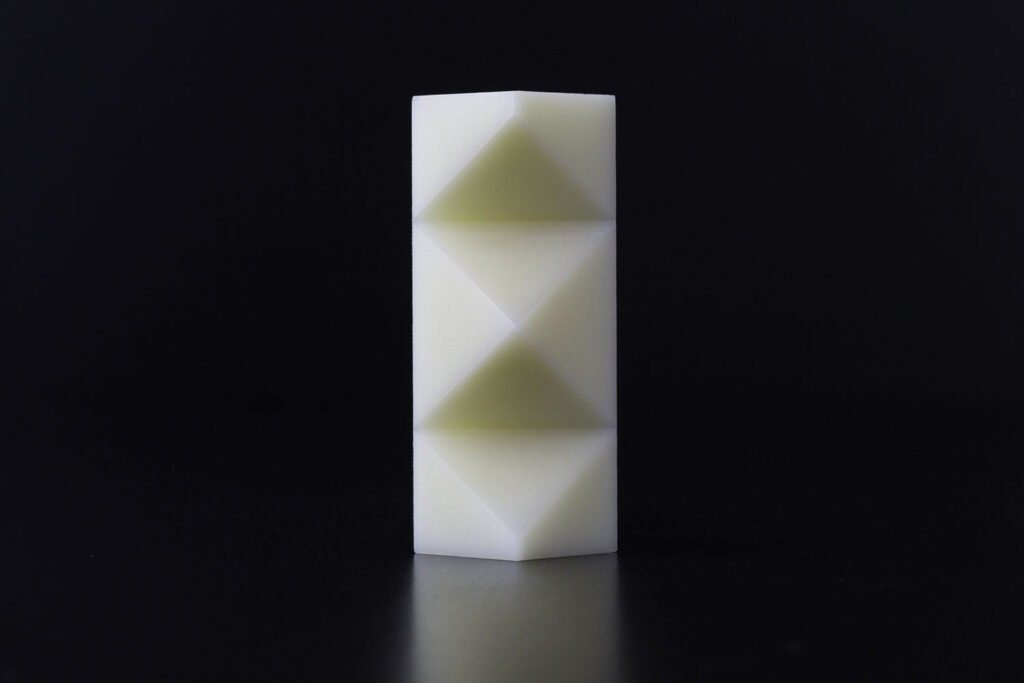

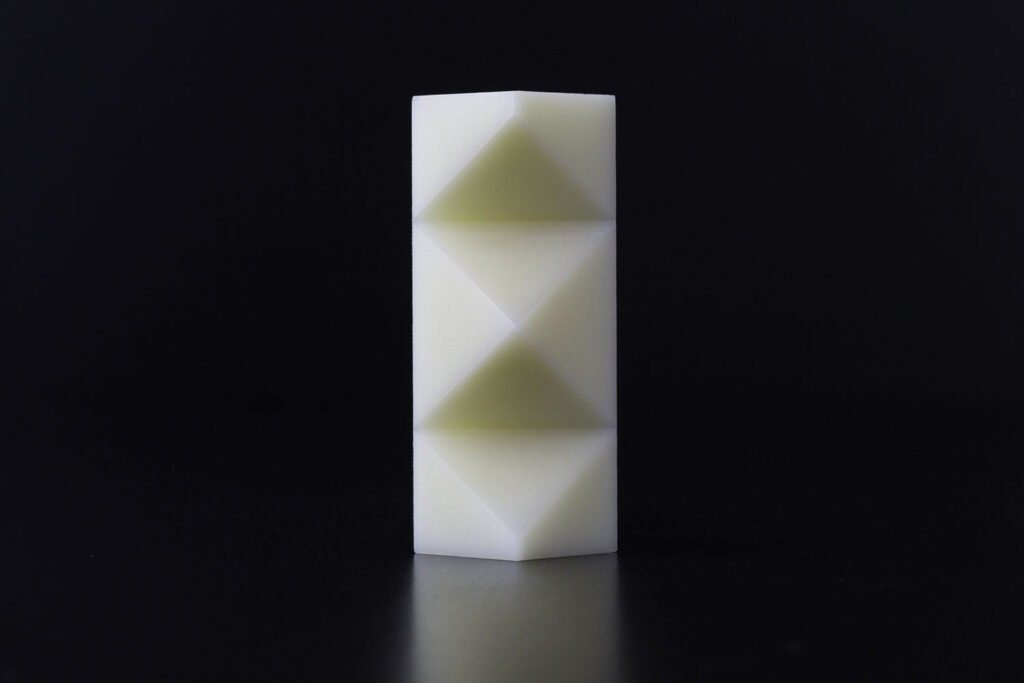

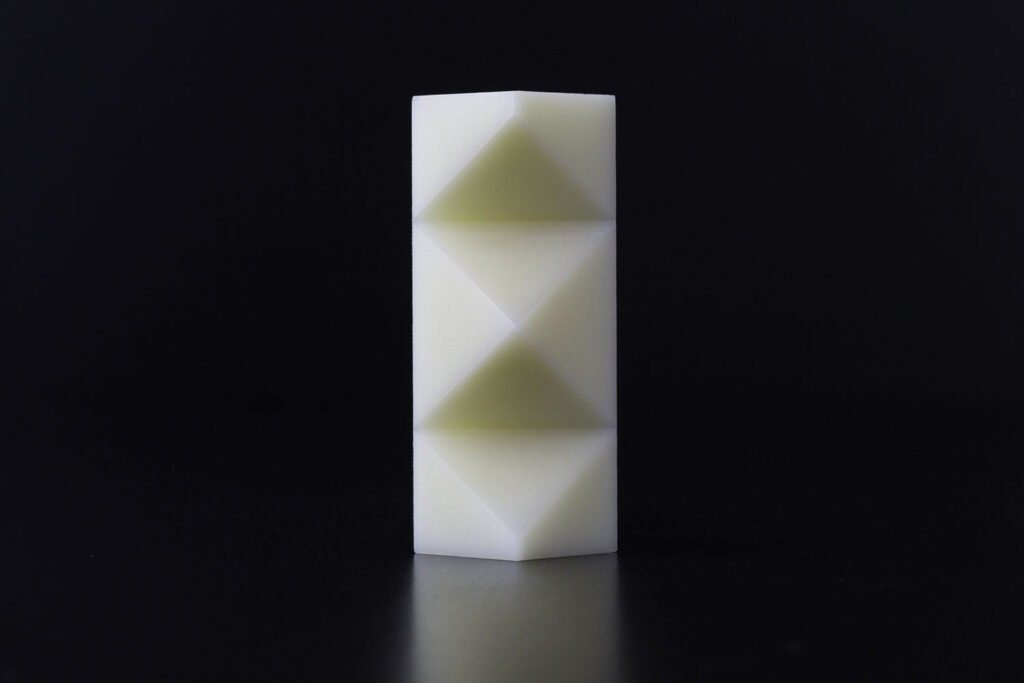

Our Latest Medical Plastic Injection Molding Products

Explore our precision-engineered medical plastic parts and see the quality for yourself. From prototyping to mass production, our high-performance components meet the strictest medical industry standards.

Precision Machining Tolerance

| Metals, PEEK, And ULTEM with Drawing | Other Plastics with Drawing | No Drawing | |

|---|---|---|---|

| Linear Dimension | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Hole Diameters (Not Reamed) | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.0025 mm +/- 0.0001 inch |

| Shaft Diameters | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

Part lengths of up to 48″ are available on our platform process dependent. Please inquire about anything larger. Tolerances listed here are minimums for an ideal case. Looser tolerances may be required depending on process, material choice, or part geometry.

Medical Plastic Injection Molding Materials

pp

Polypropylene is favored in medical injection molding for its high chemical resistance, toughness, and ability to withstand various sterilization methods. It is used for manufacturing syringes, vials, and specimen bottles that require autoclaving. For example, PP is commonly used for manufacturing medical syringes and specimen collection containers due to its durability and resistance to chemical degradation.

- Mill Lead Time: Up to 3 weeks

- Color: Natural, white, black

PE

Polyethylene is ideal for medical plastic injection molding due to its excellent chemical resistance, flexibility, and biocompatibility. These properties make it suitable for producing items such as tubing, bottles, and containers that must withstand sterilization processes. PE is widely used in medical applications, including medical packaging, surgical drapes, and blood bags. For example, PE is commonly used in the production of blood storage bags, which require flexibility and resistance to harsh chemicals.

- Mill Lead Time: Up to 3 weeks

- Color: Natural, white, black

ABS

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer produced through emulsion. Known for its excellent resistance to corrosive chemicals, it is commonly used in applications such as automotive parts, toys, and electronic housings.

ABS is easy to machine and features a relatively low melting temperature, allowing for easy molding and shaping. Its high impact resistance makes it ideal for products subject to significant stress or force. These unique properties make ABS a popular choice across various industries worldwide.

Common applications: Enclosures

PC

Polycarbonate is used in medical plastic injection molding due to its high impact resistance, transparency, and gamma radiation sterilization compatibility. It is used for manufacturing surgical instrument handles, blood oxygenators, and various medical device components. For example, PC is commonly used for surgical instruments that require transparency and durability, such as endoscopes.

- Mill Lead Time: Up to 3 weeks

- Color: Clear, transparent

PSU

Polysulfone’s high temperature resistance and excellent mechanical properties make it a strong candidate for medical plastic injection molding. It is commonly used for components requiring repeated sterilization. For example, PSU is often used for producing parts for dialysis machines and surgical instrument handles due to its ability to endure high temperatures.

- Mill Lead Time: Up to 4 weeks

- Color: Transparent amber

PET

PET is commonly used for medical plastic injection molding due to its high strength, chemical resistance, and clarity. It is ideal for items requiring transparent packaging or strong barriers. For example, PET is used for producing diagnostic test kits and medical packaging where clarity and durability are crucial.

- Mill Lead Time: Up to 3 weeks

- Color: Clear, transparent

PEEK

PEEK is highly valued in medical plastic injection molding for its superior mechanical properties, chemical resistance, and biocompatibility. It is used for applications requiring high performance and sterilization compatibility, such as surgical tools and implantable devices. For example, PEEK is commonly used in spinal implants due to its strength and ability to withstand harsh medical conditions.

- Mill Lead Time: Up to 4 weeks

- Color: Natural (tan), black

TPE

Thermoplastic Elastomers offer the flexibility of rubber with the processing ease of plastics, making them ideal for soft-touch components. TPE is commonly used for medical devices requiring flexibility, such as syringe plunger seals. For example, TPE is used for flexible grips and seals in medical applications, where softness and comfort are essential.

- Mill Lead Time: Up to 3 weeks

- Color: Various, depending on requirements

LSR

Liquid Silicone Rubber’s flexibility, biocompatibility, and resistance to high temperatures make it suitable for medical plastic injection molding. It is widely used for items requiring softness and durability, such as gaskets and seals. For example, LSR is commonly used for producing infant care products like pacifiers due to its softness and high safety standards.

- Mill Lead Time: Up to 4 weeks

- Color: Translucent, can be pigmented

Finishing Options for medical plastic injection molding

| Name | Applicable Materials | Colors | Can Be Applied with |

|---|---|---|---|

Chem Film

Chem Film

|

Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing*, Type III Anodizing with PTFE* |

Polishing

Polishing

|

ABS, Polycarbonate, PP, PE | Transparent, various colors | Manual or automated polishing machines |

Painting

Painting

|

ABS, Polycarbonate, PP, PE | Wide range of colors | Spray painting, electrostatic painting |

Laser Etching

Laser Etching

|

ABS, Polycarbonate, PP, PE | Black, white, gray | Laser engraving machines |

Texturing

Texturing

|

ABS, Polycarbonate, PP, PE | Depends on base material | Chemical etching, laser texturing |

Plating

Plating

|

ABS, Polycarbonate | Chrome, nickel, gold | Electroplating, electroless plating |

Anodizing

Anodizing

|

Aluminum | Clear, black, various colors | Type II Anodizing, Type III Anodizing |

Powder Coating

Powder Coating

|

Metal, some plastics | Wide range of colors | Electrostatic application, curing oven |

Ultrasonic Welding

Ultrasonic Welding

|

ABS, Polycarbonate, PP, PE | Depends on base material | Ultrasonic welding machines |

- *Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. For materials not listed here, please contact us directly.

medical plastic injection molding FAQs

Our partnered suppliers use high-performance materials like ABS, PP, PC, PA (Nylon), and POM, ensuring durability and heat resistance for automotive applications.

Absolutely. Our suppliers offer rapid prototyping to help you test and validate designs before full-scale production.

Standard lead times are 10-15 days, with expedited options available for urgent medical projects.

Yes, our suppliers use materials and processes that meet ISO 10993 standards for biocompatibility and sterilization.

Yes, advanced molding techniques allow for the production of complex and intricate medical components.

Rigorous quality checks, including dimensional inspections and material testing, are conducted at every stage of production.

Are You Looking for medical plastic injection molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.