Metal Injection Molding Services From China

Looking for a reliable metal injection molding partner? As a professional digital supplier, we can help. Get your metal parts more easily and at a better price.

- 50+ Certified Materials & 15+ Surface Finishing Options

- Cost-effective solutions for both prototyping and mass production

- ISO 9001:2015 Certified, ensuring global quality standards

- Extensive Digital Manufacturing Expertise with a strong supply network

Metal Injection Molding Small Batch Production

At Formioo, we depend on a mature supplier network, specializing in connecting you with high-precision metal injection molding services, providing cost-effective, reliable, and scalable manufacturing solutions for industries such as automotive, medical, electronics, and industrial equipment. Whether you need rapid prototyping or mass production, our network of trusted suppliers ensures that each part meets excellent precision and consistency.

With a trusted network of 200+ suppliers, we offer a wide range of metal injection molding services, supporting everything from rapid prototyping to mass production. Our ISO 9001:2015-certified quality system ensures tight tolerances as precise as ±0.01 mm across a wide selection of 50+ materials and 15+ finishing options.

As one of the leading digital metal injection molding service providers in China, we are committed to delivering cost-effective, high-performance parts with fast turnaround times. All of our custom-manufactured components are competitively priced without compromising on quality.

Metal Injection Molding Services

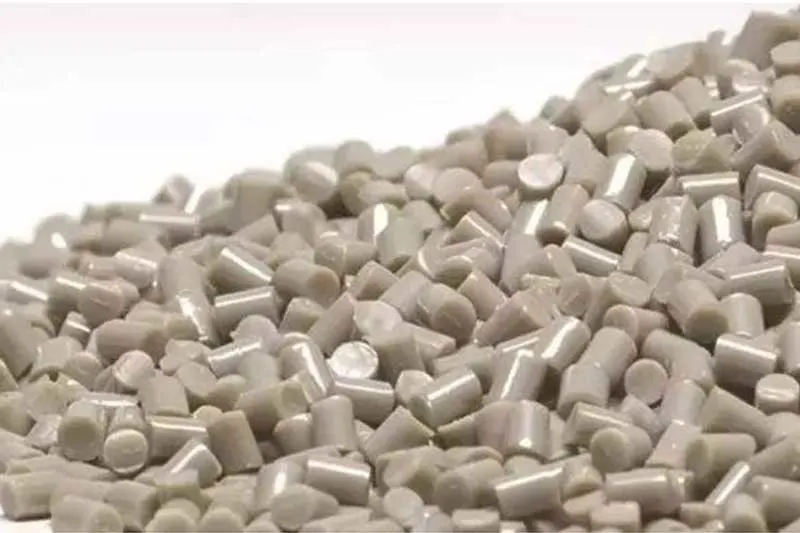

Our partner Chinese metal injection molding facility specializes in a complete process: feedstock formulation, precision injection molding, debinding, and sintering. Each step is meticulously controlled to ensure superior dimensional accuracy and robust mechanical properties. With rapid prototyping and high-volume production, we deliver cost-effective, high-quality metal components with tight tolerances, serving diverse industrial needs through our efficient digital manufacturing platform.

Combines metal powders with binders for complex shapes.

Removes binders to prepare parts for sintering.

Heats parts to fuse metal particles for strength.

Enhances part appearance and performance.

Metal Injection Molding Capabilities

Material Compatibility

Our network is capable of molding stainless steel, carbon steel, aluminum, copper, and other metal alloys, meeting various industrial and custom production needs.

Printing Accuracy

Our standard tolerance is controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Maximum Build Size

Our maximum molding size is up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Surface Finishing Options

We support polishing, anodizing, powder coating, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard metal injection molding lead time is 5-10 days, with expedited service available for urgent projects.

This is Modal Title

Our Latest Metal Injection Molded Products

Explore our precision-engineered metal injection molded parts and see the quality for yourself. From prototyping to mass production, our high-precision components meet the toughest industry standards. Visit our website to view our product gallery today!

Metal Injection Molding Materials

Stainless Steel

Stainless Steel is a highly favored material for Metal Injection Molding due to its excellent corrosion resistance, high strength, and remarkable formability. Its versatility enables the creation of intricate parts with fine details and superior dimensional accuracy. In MIM, stainless steel is widely used in manufacturing medical devices, automotive components, and consumer electronics. For example, surgical instruments, engine parts, and decorative fasteners all benefit from its durability and aesthetic appeal. The material’s ability to withstand harsh chemical environments while maintaining structural integrity makes it indispensable for precision engineering projects.

- Mill Lead Time: 3-5 days

- Finishes: Polished, matte, passivated

Tool Steel

Tool Steel is ideal for Metal Injection Molding due to its outstanding hardness, wear resistance, and heat tolerance. Its robust properties allow the production of complex, high-performance tools and components. In MIM, tool steel is commonly used in manufacturing cutting tools, dies, and high-precision gears. For instance, injection molds, stamping dies, and industrial machinery components benefit greatly from its exceptional strength and durability. The material’s capacity to retain hardness under extreme conditions makes it a top choice for demanding engineering applications, ensuring both precision and longevity.

- Mill Lead Time: 4-6 days

- Finishes: Heat treated, ground, polished

Titanium

Titanium stands out as an exceptional material for Metal Injection Molding because of its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Its lightweight nature paired with superior mechanical properties makes it ideal for producing complex components with reduced weight. In MIM, titanium is extensively applied in aerospace, medical, and automotive industries. For example, implantable devices, aircraft structural components, and high-performance engine parts all capitalize on titanium’s durability and efficiency. This unique combination facilitates innovative engineering solutions in demanding applications.

- Mill Lead Time: 5-7 days

- Finishes: Anodized, sandblasted, polished

Tungsten

Tungsten is an exceptional material for Metal Injection Molding due to its extremely high density, superior strength, and outstanding thermal properties. Its ability to withstand intense heat and harsh conditions makes it ideal for applications requiring heavy-duty performance. In MIM, tungsten is frequently used for aerospace counterweights, radiation shielding, and specialized military components. For example, ballast weights, radiation barriers, and electrical contacts benefit from tungsten’s robustness and thermal conductivity. Its integration in complex MIM processes ensures reliable performance in extreme environments, making it indispensable for advanced engineering solutions.

- Mill Lead Time: 7-10 days

- Finishes: Raw, machined, coated

PC

Polycarbonate (PC) offers exceptional toughness, clarity, and heat resistance, making it an outstanding material for insert injection molding. It integrates seamlessly with metal or fiber-reinforced inserts, enhancing the strength and durability of components. PC is widely used in electronic enclosures, medical devices, and automotive lighting applications. For example, PC is often applied to overmold metal hinges in devices, embed fasteners in transparent housings, and combine with metal inserts in secure electrical modules. Its remarkable impact resistance and optical clarity lead to high-quality, reliable designs.

- Mill Lead Time: 3 days

- Color: Transparent with available tinted variations

Polyamide (Nylon) is highly suitable for insert injection molding because of its superior strength, abrasion resistance, and thermal stability. It bonds effectively with metal inserts, ensuring robust and reliable parts. Nylon is widely used in gear housings, high-load fasteners, and mechanical components in automotive and aerospace applications. For example, it is employed to overmold threaded inserts in electrical connectors, reinforce metal frames, and manufacture durable structural elements. Its excellent performance under stress and variable conditions guarantees long-term functionality in demanding environments.

- Mill Lead Time: 4 days

- Color: Natural with a range of dye options

POM

Acetal (POM) is favored in insert injection molding for its high stiffness, low friction, and excellent dimensional stability. These characteristics enable it to bond reliably with metal or other inserts, producing robust, precision components. It is commonly used in mechanical gears, fasteners, and precision parts in automotive and electronic sectors. For instance, Acetal is employed to overmold metal bushings, secure embedded fasteners, and reinforce assembly parts for enhanced wear resistance. Its consistent processing behavior and long-term durability make it a trusted choice for high-performance engineering applications.

- Mill Lead Time: 4 days

- Color: White with versatile finish options

PMMA

PMMA is chosen for IMD due to its optical clarity and weather resistance. It is widely used in displays, light guides, and automotive windows. For example, PMMA is used in smartphone screen covers for its scratch resistance and transparency.

- Mill Lead Time: Up to 5 days

- Color: Transparent, custom colors

PBT

PBT (Polybutylene Terephthalate) is a high-performance engineering thermoplastic known for its excellent mechanical strength, heat resistance, and electrical insulation properties. It offers high dimensional stability, low moisture absorption, and good chemical resistance, making it ideal for automotive components, electrical connectors, and industrial applications. PBT can be reinforced with glass fiber for enhanced strength and durability. Its reliability and processing ease make it a preferred material for precision-molded parts.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PEEK

PEEK is suitable for IMD in high-temperature and chemical-resistant applications. It is used in aerospace, medical implants, and automotive components. For example, PEEK is used in engine components for its thermal stability and strength.

- Mill Lead Time: Up to 7 days

- Color: Natural, black, custom colors

PPS

PPS is chosen for IMD due to its high thermal stability and flame resistance. It is used in electrical components, automotive parts, and industrial applications. For example, PPS is used in connectors and sensors for its dimensional stability and resistance to harsh environments.

- Mill Lead Time: Up to 7 days

- Color: Natural, black, custom colors

LCP

LCP (Liquid Crystal Polymer) is a high-performance thermoplastic known for its exceptional mechanical strength, high-temperature resistance, and excellent dimensional stability. It offers outstanding chemical resistance, low moisture absorption, and superior flow properties, making it ideal for micro-precision components in electronics, automotive, medical, and aerospace applications. LCP is commonly used in connectors, circuit boards, and other high-heat environments where stability and reliability are critical.

- Production Lead Time: As fast as 7 days

- Color: Natural, Black, Custom Colors Available

PVDF

PVDF material (chemical name Polyvinylidene fluoride) is processed by Ensinger in standard product shapes in sheets and rods. Polyvinylidene fluoride is an opaque, semi-crystalline, thermoplastic fluoropolymer. PVDF has excellent chemical resistance without the low mechanical values and/or processing difficulties often encountered with other fluoropolymer materials. The melting point of PVDF material is 171 degrees Celsius.

PI

PI is an ideal choice for aerospace injection molding due to its exceptional thermal stability, mechanical strength, and resistance to wear. It is suitable for high-temperature applications and complex geometries. PI is widely used in aerospace for bearings, seals, and insulation components. For example, jet engine bearings and thermal insulation parts often use PI for its durability.

- Mill Lead Time: Up to 6 days

- Color: Natural, brown, or custom finishes

Finishing Options for Metal Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with |

|---|---|---|---|

Polished Finish

Polished Finish

|

Stainless Steel, Titanium, Aluminum | Mirror-like, natural metallic | Mechanical polishing, buffing |

Anodized Finish

Anodized Finish

|

Aluminum, Titanium | Aluminum, Titanium | Electrochemical anodizing |

Bead Blasted Finish

Bead Blasted Finish

|

Stainless Steel, Tool Steel, Titanium | Matte gray, natural | Media blasting, sandblasting |

Powder Coated Finish

Powder Coated Finish

|

Stainless Steel, Aluminum, Tool Steel | Wide range: white, black, red, blue | Powder coating, curing ovens |

Electroplated Finish

Electroplated Finish

|

Stainless Steel, Titanium, Copper | Chrome, nickel, gold, silver | Electroplating, chemical deposition |

Etched Finish

Etched Finish

|

Stainless Steel, Aluminum, Titanium | Natural (color enhancement possible) | Chemical etching, laser etching |

Passivated Finish

Passivated Finish

|

Stainless Steel, Tool Steel | Natural, matte | Acid treatment, chemical passivation |

Machined Finish

Machined Finish

|

Stainless Steel, Tool Steel, Titanium | Uniform silver metallic | CNC machining, milling, turning |

- *Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. For materials not listed here, please contact us directly.

Metal Injection Molding FAQs

We work with stainless steel, titanium, copper alloys, and more. Let us know your material requirements.

Absolutely! Metal Injection Molding excels at producing intricate, high-precision parts that are hard to achieve with traditional methods.

We achieve tolerances as tight as ±0.3% of the part dimension, ensuring precision for demanding applications.

Yes, we provide machining, polishing, plating, and heat treatment to meet your final part specifications.

We cater to both small and large volumes, but MOQs depend on part complexity. Let’s discuss your needs.

Our rigorous material selection and process controls guarantee consistent quality across every batch.

Are You Looking for Metal Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.