3D Printing Service for Custom Parts

Formioo offers on-demand 3D printing for rapid prototyping and production in as fast as 3 days. Support complex geometries, fast design iterations, and low-volume runs.

- 10+ years of 3D printing experience

- High-Precision 3D Printing with tolerances from as low as ±0.2 mm

- 50+ Certified Materials & 15+ Surface Finishing Options

- Printing over 250,000 parts per month

- 3-7 days fast turnaround

Your Go-To One-Stop High-Precision 3D Printing Manufacturer

Formioo is a professional 3D printing manufacturer in China, providing on-demand additive manufacturing solutions for rapid prototyping and low-volume production. With full printing technology and advanced digital workflows, we support fast turnaround, complex geometries, and custom part requirements for diverse design and engineering needs.

Our experienced engineering team supports you at every stage, from 3D model optimization and DFAM (Design for Additive Manufacturing) to material selection and tolerance analysis. We work closely with you to ensure that every 3D printed part meets both performance and cost objectives, helping accelerate development while minimizing risks.

With over 10 years of experience in 3D printing, Formioo delivers thousands of custom 3D printed parts every year. We serve clients across industries such as consumer electronics, automotive, medical devices, robotics, and industrial equipment, providing dependable support from early-stage development to final validation.

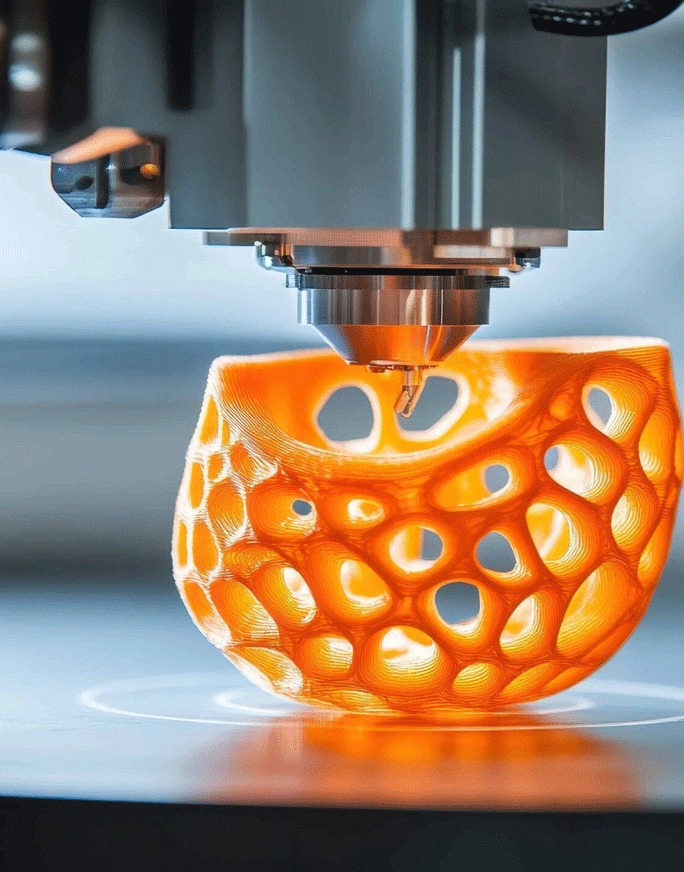

Our 3D Printing Technologies

Formioo offers a full suite of industrial 3D printing technologies, including SLA (stereolithography), SLS (selective laser sintering), MJF (Multi Jet Fusion), and FDM (fused deposition modeling). These processes support a wide range of applications, from visual prototypes to functional end-use parts. We work with various high-performance materials such as nylon (PA12), ABS-like resins, TPU, PC, PETG, and carbon fiber-reinforced filaments to meet diverse requirements for strength, flexibility, heat resistance, and detail resolution.

To meet both aesthetic and performance standards, we offer a variety of post-processing and surface finishing options, including sanding, polishing, dyeing, painting, vapor smoothing, and clear coating. Depending on the technology and material used, our 3D printing processes can achieve tolerances as tight as ±0.1 mm for SLA and ±0.3 mm for SLS/MJF, ensuring consistent quality and dimensional accuracy. Each part is inspected to meet design specifications and end-use expectations.

SLA works with photopolymers but with high precision and fine details.

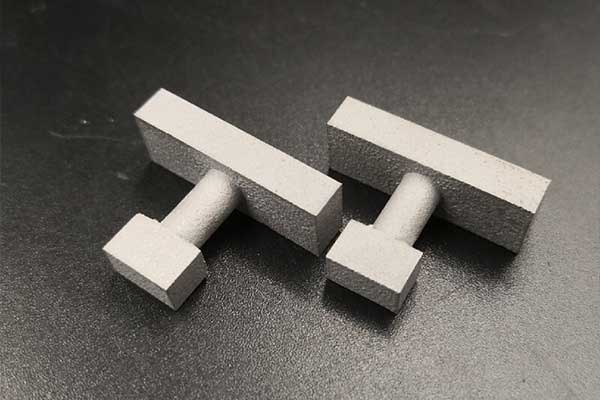

SLS-printed parts have good mechanical properties and are often used for functional parts.

SLM uses a laser to heat metal powders to create high-strength, complex metal parts.

MJF fuses nylon powder precisely, with a product that is strong, detailed, and durable, with durable parts that last long.

3D Printing Capabilities

Material Compatibility

Prints using nylon, ABS, resin, TPU, metal powders, and engineering plastics, for diverse prototyping and functional part needs.

Printing Accuracy

Standard tolerance within ±0.05mm, with high precision for prototypes, industrial parts, and end-use parts.

Maximum Printing Size

Accommodates up to 500mm × 500mm × 500mm for smaller and medium-sized pieces.

Surface Finishing Options

Offers polishing, painting, plating, vapor smoothing, and dyeing for increased strength and visual appeal.

Delivery Time

Standard 3D printing lead time of 3-7 days with option for rush service for urgent projects.

Massive Network

We work with trusted 3D printing suppliers.

Explore 3D Printed Parts We Manufactured

See our high-quality 3D printed parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

3D Printing Tolerance

| Name | Tolerance Range |

|---|---|

| Fused Deposition Modeling (FDM) | +/- 0.2 mm to +/- 0.5 mm |

| Stereolithography (SLA) | +/- 0.05 mm to +/- 0.1 mm |

| Selective Laser Sintering (SLS) | +/- 0.1 mm to +/- 0.3 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

3D Printing Materials

PLA

PLA (Polylactic Acid) is a thermoplastic obtained from a renewable resource-based material that can degrade biologically. It is extensively used in 3D printing as it is easy to print, has low-warp behavior, and is eco-friendly. PLA has good surface finish, rigidity, and dimensional stability, therefore best for concept models, prototypes, and show pieces. It does not contain the heat and impact strength of ABS. PLA can also be printed in a variety of colors and post-processed using sanding or painting for additional finishing.

- Production Lead Time: As fast as 5 days

- Color: White, Black, Red, Blue, Natural, Custom Colors Available

ABS

Acrylonitrile Butadiene Styrene (ABS) is a strong, impact-resistant thermoplastic commonly used for 3D printing for its toughness, heat resistance, and superior impact strength. ABS is stable chemically with mechanical stability and can be used in functional models, automotive components, domestic appliances, and industry. It may be readily post-processed using sanding, paint, and acetone smoothing for cosmetics. Its flexural toughness, strength, and low cost make it an ideal choice for long-lasting and stiff 3D-printed parts.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

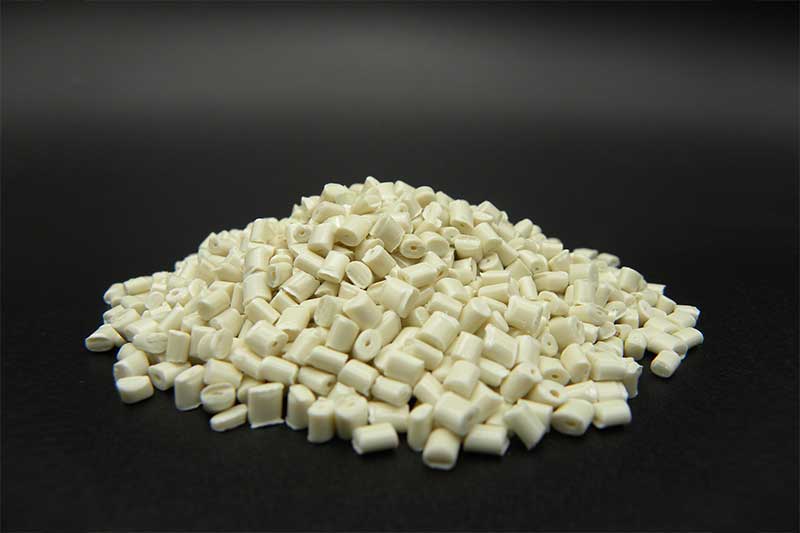

Nylon

Polyamide, PA, or Nylon is a readily available, hard thermoplastic that has overall application in 3D printing because of its strength, flexibility, and abrasion resistance. Nylon offers greater mechanical strength, chemical resistance, and thermal stability and can be used for functional models, gears, hinges, and industrial parts. Lubricity of Nylon can be applied to sliding parts, and its toughness is used to the best advantage for thin-walled long-life articles. Nylon is stainable, machinable, or coat-able to provide long-lasting appearance and performance.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Natural, Custom Colors Available

TPU

Thermoplastic Polyurethane or TPU is a hard but elastic polymer that is widely applied in 3D printing due to its impact strength, wear resistance, and elasticity. It has improved mechanical strength, weatherability, and chemical resistance, and can be applied in seals, gaskets, footwear, medical devices, and soft molds. The rubber-like characteristics of TPU offer excellent shock absorption and flexibility, with excellent printability and durability. It is colorable, coat-able, or texture-able for enhanced functionality and cosmetic purposes.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

Standard Resin

Standard Resin is a high-gloss, high-definition material widely used in 3D printing for its excellent surface finish and accuracy. It can be used for conceptual models, prototypes, figurines, and visual presentation parts due to its resolution and detailed reproduction. Though less impact resilient than thermoplastics, Standard Resin has good stiffness and size accuracy and is suitable for appearance and design validation applications.It can be sanded, painted, or coated to improve finish and functionality.

- Production Lead Time: As fast as 7 days

- Color: White, Gray, Black, Clear, Custom Colors Available

Tough Resin

Tough Resin is a high-performance, impact-absorbing resin well liked for 3D printing because it has better toughness and durability. It is developed to replicate ABS-like mechanical behavior with excellent shock-absorbing capacity, high tensile strength, and wear resistance for tooling, functional models, and mechanical parts. Tough Resin boasts good stiffness and stability, and stable performance under stress. It can be sandable, paintable, and coat-able to achieve additional functionality and aesthetics.

- Production Lead Time: As quick as 7 days

- Color: White, Black, Gray, Custom Colors Available

Transparent Resin

Transparent Resin is a high-transparency resin widely used in 3D printing as a result of surface smoothness and high transparency. It is ideal for optical models, light guides, lenses, and appearance models, with good stiffness and extremely fine detail resolution. Having less impact resistance than thermoplastics, can be polished or coated to enhance clarity and transparency and hence is suited best where visual appearance and precision are necessary.

- Production Lead Time: As quick as 7 days

- Color: Clear, Translucent, Custom Tints Available

High-Temperature Resin

High-Temperature Resin is temperature-resistant resin utilized with high frequency for 3D printing heat durability and longevity. Of high heat deflection temperature (HDT), it is utilized in automotive, aircraft, and industrial tooling components resisting harsh heat. It is very stiff, chemically resistant, and provides high detail resolution, ideal for functional testing and high-performance applications. Post-curing enhances its mechanical strength and resistance to heat, resisting heat stress, and providing consistent performance.

- Production Lead Time: Up to 7 days

- Color: White, Gray, Black, Custom Colors Available

Stainless Steel

Stainless Steel is wear-resistant high-strength metal with extensive applications in 3D printing due to enhanced mechanical properties, wear resistance, and high strength. It is applicable in medical, aerospace, auto, and industrial applications, in addition to being chemical and heat resistant. 17-4 PH and 316L are common grades and possess superior toughness, machinability, and balance of strengths. Stainless Steel parts can be polishable, sandblastable, or passivatable in order to enhance the surface condition and performance.

- Print Lead Time: 5 days maximum

- Finishes: Raw, Polished, Sandblasted, Passivated

Aluminum

Aluminum is a tough, light metal utilized all over in 3D printing due to its corrosion resistance, improved mechanical strength, and high conductance. Aluminum offers a tough and light solution for high-performance parts perfectly appropriate for aerospace, automotive, electronic, and industrial uses. Grades like AlSi10Mg are popularly applied owing to their superior machinability and mechanical characteristics. Anodized, bead-blasted, or polished aluminum components can be supplied for enhanced surface finish and esthetics.

- Print Lead Time: 5 days or less

- Finishes: Raw, Polished, Anodized, Bead Blasted

Titanium

Titanium is a light but very strong metal that finds extensive use in 3D printing because of its high heat resistance, biocompatibility, and corrosion resistance. It possesses excellent usage in aerospace, medical implant devices, automotive components, and high-performance engineering uses. It possesses a high strength-to-weight ratio. Ti6Al4V (Grade 5) is one of the most popular grades with exceptional strength and life. The titanium components are sandblasted, polished, or anodized for enhanced functionality and appearance.

- Print Lead Time: Within 7 days at the earliest

- Finishes: Raw, Polished, Sandblasted, Anodized

Copper/Brass

Copper/Brass is a good conductive and anti-corrosion metal widely applied in 3D printing because it is highly electric and thermal in nature. Copper/Brass finds application for use in electronics, heat exchangers, cosmetic components, and industrial purposes with high machinability and durability. Brass and pure copper are popular grades and go by high antimicrobial properties and appearance.” Copper and brass components can be polished, sandblasted, or coated to achieve improved quality and look.

- Print Lead Time: 7 days maximum

- Finishes: Raw, Polished, Sandblasted, Coated

Carbon Fiber Reinforced Nylon

Carbon Fiber Reinforced Nylon is a light, high-strength composite material applied in large quantities in 3D printing on account of its large stiffness, strength, and thermal stability. Its mechanical properties are very good, with it being well-suited for application in the automotive, aerospace, tooling industry, and functional prototypes markets. It possesses rigidity and dimension stability by carbon fiber reinforcement and good impact resistance with low weight. It is well-suited for application in the mechanical loading applications of high performance.

- Production Lead Time: As fast as 7 days

- Color: Black, Gray, Custom Colors Available

Glass Fiber Reinforced Plastic

Glass Fiber Reinforced Plastic (GFRP) is heat-resistant and stiff plastic resin widely used in 3D printing because of its stiffness, toughness, and strength. The reinforcement by glass fiber enhances the structural stiffness and impact strength and is thus designed for use in industrial tooling, load-carrying structure, automobile, and aerospace applications. GFRP is dimensionally more stable and lighter in weight than their metal counterparts and are a cost-effective option for high-performance applications.

- Production Lead Time: As short as 7 days

- Color: White, Black, Gray, Custom Colors Available

Ceramic-Based Composites

Ceramic-Based Composites are dimensionally stable, high-temperature-resistant materials that are used extensively for 3D printing applications owing to applications with enhanced thermal stability, electrical insulation, and wear resistance. They are highly chemical-resistant and hard and are used in hostile environments, aerospace systems, medical applications, industrial tooling, and high-temperature applications. Ceramic-based components provide dimension stability in hostile environments and can be polished or coated for their enhanced surface properties.

- Production Lead Time: As fast as 7 days

- Color: White, Gray, Custom Colors Available

Finishing Options for 3D Printing

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Bead Blasting | Metal, Plastic, Resin | Natural, Matte | Abrasive Media Blasting |

|

Polishing | Metal, Resin, Plastic | Glossy, Smooth | Manual Polishing, Machine Buffing |

|

Electroplating | Metal (e.g., Stainless Steel, Aluminum) | Silver, Gold, Chrome | Electrolytic Process |

|

Smoothing (Vapor or Chemical) | Resin, Plastic | Glossy, Smooth | Vapor Smoothing (e.g., Acetone for ABS) |

|

UV Coating | Resin, Plastic | Clear, Matte, Glossy | UV Curing Lamps, Coating Equipment |

|

Painting | Resin, Plastic, Metal | Wide range of colors | Spraying, Airbrush |

|

Dyed Finishing | Resin, Plastic | Custom colors (depending on dye) | Immersion in dye solutions |

|

Laser Etching/Marking | Metal, Plastic, Resin | Natural, Black | Laser Machines |

|

Anodizing | Metal (mainly Aluminum) | Clear, Black, Custom | Electrolytic Process (limited to metal parts) |

|

Surface Sealing | Resin, Plastic | Clear, Glossy | Surface Sealing Coating |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your 3D Printing Supplier Selection Ultimate Guide

Which 3D printing supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo 3D Printing FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What are your tolerances for 3D printing?

Formioo’s standard 3D printing tolerance is ±0.1mm, but it may vary with part complexity. Upload your custom design that will be rated by our experts.

How long does 3D printing take?

3 to 7 days average lead times based on material, part complexity, and post-processing requirements. Rush options are available.

What's the biggest size of 3D prints?

Formioo accommodates various sizes: FDM: 36 x 24 x 26 in SLA: 29 x 25 x 21 in SLS: 26 x 15 x 23 in Polyjet: 19 x 15 x 7 in.

Which file types do you accommodate?

Formioo accommodates STEP (.stp) and STL (.stl) types for precision. For other types, use STEP or STL, or contact our support for assistance.

How costly is your 3D printing?

Pricing depends on printer model, part size, material, and quantity. Formioo gives you correct quotes according to your project specifications.

Do you offer design support or file optimization?

Yes! Our engineers can review, improve, and suggest modifications to offer the best quality print.

Which markets do you deal in?

Automotive, medical, electronics, aerospace, consumer product, and industrial manufacturing purchasers.

How do I select a 3D printing technology?

Select by material, strength, finish, and cost: SLA: High-gloss finish SLS/HP MJF: Tough components FDM: Large, inexpensive parts SLM: High-strength metal components Our expert consultative services.

Do you produce small-batch or even prototypes?

Yes! We do rapid prototyping as well as small-batch production with quality and consistency at scale.

3D Printing Resource

Are You Looking for 3D Printing Service in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.