One-Stop Urethane Casting Manufacturing Solution

Formioo provides urethane casting services for high-quality prototypes and low-volume production using silicone molds. Low MOQ and fast lead times, perfect for flexible, cost-efficient short runs.

- Instant quotes & DFM feedback

- Wide range of metals and plastics available

- 0.2–0.5 mm tolerance

- Receive your parts in as little as 7 days

Reliable Urethane Casting Manufactuer from China

Formioo is a professional urethane casting manufacturer in China, specializing in high-quality prototypes and short-run production using silicone molds. Our facility is equipped to handle complex geometries, tight tolerances, and customized surface finishes, offering a flexible and cost-effective alternative to injection molding for low-volume needs.

At Formioo, our urethane casting service is built for flexibility, helping customers quickly produce high-quality parts without the cost and lead time of hard tooling. Whether you’re launching a new product, testing a functional design, or fulfilling early orders before ramping up mass production, we make it easier to move fast with small-batch production. Our team assists with design optimization, material matching, and color reproduction to ensure every part meets both technical requirements and visual standards—while keeping MOQs low and lead times short.

With over 10 years of manufacturing experience, Formioo has delivered thousands of cast polyurethane parts across industries, including medical, consumer electronics, automotive, robotics, and industrial equipment. We support startups and global brands alike in turning product concepts into market-ready parts with speed and reliability.

Explore Our Urethane Casting Capabilities

Formioo offers a full range of urethane casting capabilities, including Vacuum Casting, Gravity Casting, Pressure Casting, and Reaction Injection Molding (RIM). These processes allow us to replicate complex geometries with excellent surface quality using silicone molds. We work with a wide variety of polyurethane materials that simulate ABS, PC, PP, rubber, and even high-transparency or flame-retardant plastics, enabling tailored performance in flexibility, impact strength, and heat resistance.

To enhance function and appearance, we offer a selection of finishing options such as painting, polishing, texture replication, color matching, and clear coating. Depending on part size and material, we can achieve dimensional tolerances of ±0.2–0.5 mm, making urethane casting ideal for cosmetic prototypes, functional parts, and bridge production. Every part is carefully inspected to ensure consistent quality and fit for downstream assembly or testing.

Casts polyurethane under vacuum to improve precision, reduce bubbles, ideal for high-quality prototypes.

Relies on gravity to pour polyurethane into molds, simple process, suitable for low-cost, medium-precision parts.

Makes use of pressure to increase material density, reduce voids, and enhance strength, best suited for high-performance parts.

Polyurethane high-pressure mixing and injection into molds, best suited for large, low-density industrial products.

Urethane Casting Capabilities

Material Compatibility

Formioo offers a wide range of urethane casting materials, from flexible to rigid, clear to color-matched materials, best suited for a wide variety of industrial and custom uses.

Casting Accuracy

Our urethane casting process is highly accurate, with default tolerance set to ±0. 2mm, and is applicable for prototypes, low volume production, and complex parts.

Maximum Build Size

We can produce urethane cast parts up to 30 inches in length, accommodating small to medium-sized components.

Surface Finishing Options

We provide multiple finishing options, including polishing, painting, and EMI shielding for improved functionality and aesthetics.

Delivery Time

Our urethane casting services offer fast lead times, typically 5-10 days for prototyping, with expedited options available for urgent projects.

Massive Network

We work with trusted urethane casting suppliers.

Explore Urethane Casting Parts We Manufactured

See our high-quality urethane casting parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Urethane Casting Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Urethane Castings | +/- 0.2 mm to +/- 0.5 mm |

| Precision Urethane Castings | +/- 0.1 mm to +/- 0.2 mm |

| Complex/Intricate Parts | +/- 0.5 mm to +/- 1.0 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

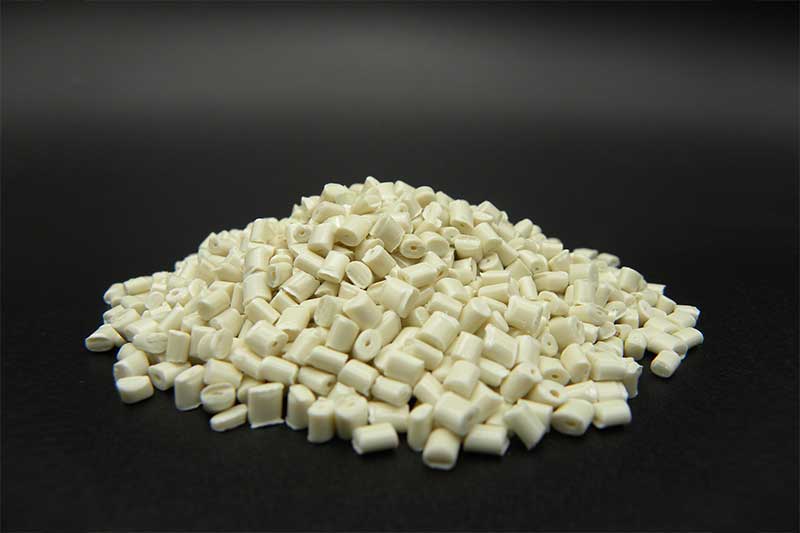

Urethane Casting Materials

ABS-Like

ABS-Like Urethane is a very flexible casting material whose characteristics are comparable to ABS plastic when it comes to resisting high impact, heat, and moldability. It possesses fair mechanical strength, thermal resistance, and chemical stability and is ideally used for prototyping car parts and low-volume manufacturing of consumer items and functional models. It can be easily painted, plated, or textured for additional functionality and appearance.

- Production Lead Time: Up to 5-10 days

- Color: White, Black, Gray, Custom Colors Available

Nylon-Like

Nylon-Like Urethane mimics the features of Nylon, including wear resistance, hardness, and low friction. It must be used where strength and long-life operation are required, i.e., mechanical components, bearings, and gears. It can maintain good strength, chemical resistance, and dimensional stability, thus applied to automobile, industrial, and electronic parts. Nylon-Like urethane can easily be machined and painted to achieve additional functionality and aesthetics.

- Production Lead Time: As fast as 5-10 days

- Color: White, Black, Gray, Natural, Custom Colors Available

Polypropylene-Like

Polypropylene-Like Urethane mimics the properties of Polypropylene, offering excellent chemical resistance, flexibility, and low-cost production. This material is ideal for parts exposed to chemicals and harsh environments, such as fluid handling components, containers, and valves. It combines ease of processing with good strength and impact resistance, making it suitable for automotive, industrial, and consumer goods applications. Polypropylene-Like urethane can also be customized with various finishes for improved performance and aesthetics.

- Production Lead Time: As fast as 5-10 days

- Color: White, Black, Gray, Natural, Custom Colors Available

Rubber-Like

Rubber-Like Urethane is very flexible, has superior tear strength, and is very resiliency-resistant, and is thus justifiably deserving of use in such applications that consist of soft, flexible components. It is closer to rubber in property but is tougher and possesses superior abrasion and thus finds use in seals, gaskets, bumpers, and cushioning components. It will blend the benefits of rubber and urethane, i.e., ease of processing and long-term durability with long-term performance by industries like automobile, electronics, and consumer goods.

- Production Lead Time: 5-10 days at most

- Color: White, Black, Gray, Natural, Custom Colors Available

Polycarbonate-Like

Polycarbonate-Like Urethane imitates Polycarbonate performance, and it is characterized by high impact strength, optical clarity, and toughness. It finds maximum suitability in clarity and strength uses, including light covers, lenses, and protective casings. The material has outstanding durability and resistance to cracking, optimally suited for consumer electronics, auto components, and protective headgear. Polycarbonate-Like urethane is also easy to process and can be painted or textured for secondary functionality.

- Production Lead Time: Up to 5-10 days

- Color: Clear, White, Black, Gray, Custom Colors Available

TPE-Like

TPE-Like Urethane mimics the performance of Thermoplastic Elastomers (TPE), trading the rubbery flexibility against the processability of the plastic. It is more elastic, tougher, and abrasion-resistant and thus best suited for soft-touch grips, overmolded parts, and elastic uses. TPE-Like urethane possesses high impact strength and is moldable into complex geometries with ease, and thus proves to be a good all-around material for automotive, medical, and consumer products markets.

- Production Lead Time: As fast as 5-10 days

- Color: White, Black, Gray, Natural, Custom Colors Available

High-Temperature Urethane

High-Temperature Urethane is designed to withstand demanding heat with added heat stability and resistance. It will maintain mechanical strength and toughness when subjected to high heat conditions and is thus best used for high-performance application in the automotive, aerospace, and industrial sectors. The product will be more thermally stable, chemically resistant, and resistant to long-term reliability when exposed to heat, offering higher life of performance for critical components subject to severe heat.

- Production Lead Time: As fast as 5-10 days

- Color: White, Black, Gray, Natural, Custom Colors Available

Finishing Options for Urethane Casting

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Bead Blasting | Urethane, Rubber, Plastic | Natural, Matte | Abrasive Media Blasting |

|

Polishing | Urethane, Rubber, Plastic | Glossy, Smooth | Manual Polishing, Buffing Wheels |

|

Spray Coating | Urethane, Rubber, Plastic | Wide range of colors | Air Spraying, HVLP Spray Gun |

|

Painting | Urethane, Rubber, Plastic | Custom colors | Airbrush, Spray Guns, Dip Coating |

|

UV Coating | Urethane, Rubber, Plastic | Clear, Glossy | UV Curing Lamps, Coating Equipment |

|

Laser Etching/Marking | Urethane, Rubber, Plastic | Natural, Black | Laser Machines |

|

Dyed Finishing | Urethane, Rubber, Plastic | Custom colors | Immersion in dye solutions |

|

Surface Sealing | Urethane, Rubber, Plastic | Clear, Glossy | Surface Sealing Coating |

|

Textured Finishing | Urethane, Rubber, Plastic | Matte, Natural | Texturing Tools, Mold Surface Finishing |

|

Electroplating | Urethane, Metal Substrate | Gold, Silver, Copper | Electroplating Process |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Urethane Casting Supplier Selection Ultimate Guide

Which urethane casting supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our latest supplier guide.

Formioo Urethane Casting Service FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Why choose urethane casting over 3D printing?

One of the greatest advantages of urethane casting over 3D printing is the material performance and quality it offers. Urethane casting uses materials that closely resemble commercial production materials, and they possess enhanced mechanical properties with greater durability. Additionally, parts made from urethane casting generally have a better fit and finish than 3D-printed parts. If you are most concerned about material functionality and a luxury appearance, then urethane casting is the technique you must utilize.

Why use urethane casting instead of injection molding?

The most important consideration in choosing injection molding versus urethane casting is volume of production. Urethane casting is an economic method for low-volume production, approximately 50 units, of production-quality product with less up-front cost of the tool than injection molding. It is therefore an ideal option for short-run production or verification of design prior to large-scale production. Many clients employ urethane casting as an in-process step to test and iterate with their designs before investing in injection molding tooling.

How do I get urethane casting quote from Formioo?

It is easy and quick to obtain a polyurethane casting quote from Formioo. Just visit our website and utilize our online quoting system to begin. Upload your STEP file via one of our supported file formats like STEP, STP, IGS, IGES, PRT, SLDPRT, SAT, and X_T to be processed successfully.

Enter your project requirements after uploading your file, including material type, finish surface, shipping conditions, and quantity. Our experienced project engineers will thereafter check for manufacturability for feasibility. After the design and specifications have been finalized, you will receive a comprehensive quotation with true costing and estimated delivery date. (Please note that instant quotes for polyurethane casting are not yet available on our platform.)

If our quote we have given here is acceptable to you, you are free to order directly on the site, and we will go ahead with the production process according to your specifications. Formioo’s streamlined system makes it easy to receive an accurate quote and begin your polyurethane casting endeavor with confidence.

Can urethane casting be used for production-quality parts?

While urethane casting is primarily appropriate for visually appealing prototypes, it can also be used for non-mechanical end-use products such as enclosures, cases, and covers.

What happens to the silicone molds? Can I Keep Them?

Silicone molds used in the process of urethane casting are of a limited working life, and hence they can last up to around 20 cycles before breaking down. Because of this, we typically discard them after use. Should you prefer retaining the 3D-printed or CNC-machined master model used in the production of the mold, please contact us personally so that we may talk.

Urethane Casting Resource

Are You Looking for Urethane Casting Supplier in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.