Custom Thin-wall Injection Molding Services

Formioo provides precision thin-wall injection molding services for lightweight, high-strength parts, offering fast turnaround times, tight tolerances, and support for complex geometries in demanding applications.

- Over 10 years of experience in thin-wall injection molding

- Thin-wall Injection Moulding with uniform wall thickness and close tolerance

- Widely range of high-flow polymer material to ensure durability and functionality

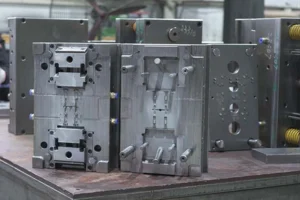

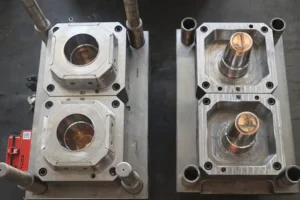

- Advanced mold design and high-speed injection capabilities for fast production cycles

Reliable Thin-wall Injection Molding Supplier from China

Formioo is a thin-wall injection molding manufacturer in China for lightweight and dimensionally stable plastic parts. With high-speed injection molding machines, in-house mold design, and rapid tooling capabilities, we support fast prototyping and production of thin-walled components with complex geometries and fast cycle times.

Our engineering team provides dedicated DFM (Design for Manufacturability) support to address the unique challenges of thin-wall parts, such as flow hesitation, warping, and short shots. We help clients optimize gate location, cooling channels, and wall thickness distribution to ensure uniform filling, strength retention, and part reliability. Whether for food packaging, medical trays, or consumer electronic casings, our solutions deliver both structural performance and production efficiency.

Since 2016, Formioo has produced thousands of thin-wall injection molded parts for customers across industries, including electronics, medical, automotive, and consumer packaging. Our ability to handle low-volume prototypes and scale up to stable, high-speed production makes us a dependable partner for time-sensitive and cost-driven manufacturing needs.

Thin-wall Injection Mold & Parts We Manufactured

Formioo specializes in producing thin-wall injection molded parts such as food containers, medical trays, electronic device housings, battery enclosures, and high-speed packaging components. These parts require consistent wall thickness, high dimensional stability, and fast-cycle production. We support a wide range of engineering and commodity plastics suitable for thin-wall molding, including PP, PS, ABS, PC, HDPE, and high-flow grades of PBT and PA, ensuring optimal flowability and mechanical strength for demanding applications.

To meet both structural and aesthetic requirements, we offer a variety of molding techniques, including high-speed injection molding, multi-cavity tooling, and hot runner systems optimized for thin-wall geometry. For enhanced surface quality and performance, we provide finishing options such as mold texturing, polishing, laser etching, pad printing, and ultrasonic welding. With process control and precision tooling, we maintain consistent part quality with tolerances typically within ±0.05–0.10 m,m depending on part size and material.

Thin-wall Injection Molding Capabilities

Material Compatibility

We offer thin-wall injection molding with high-flow polymers like PP, PS, ABS, PC, PET, and medical-grade material to meet different industrial and custom production demands.

Molding Precision

Our standard tolerance is controlled within ±0.05mm, ensuring high precision for lightweight and durable plastic components.

Maximum Build Size

We are able to manufacture thin-wall components with dimensions of up to 600mm × 400mm × 200mm, suitable for small to medium-sized parts.

Surface Finishing Options

We support texturing, polishing, silk-screen printing, UV coating, and electroplating for enhanced aesthetics and functionality.

Delivery Time

Our standard injection molding lead time is 7-15 days with rush ordering options for expedited processing.

Massive Network

We work with trusted thin-wall injection molding suppliers.

This is Modal Title

[contact-form-7 id="852" title="Contact Us"]

Our Latest Thin-wall Injection Molded Products

Explore our high-precision thin-wall injection molded parts and experience the quality firsthand. From lightweight packaging to durable medical components, our expertly manufactured products meet the highest industry standards.

Thin-wall Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Thin-Wall Parts | +/- 0.2 mm to +/- 0.5 mm |

| High-Precision Thin-Wall Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Thin-Wall Parts | +/- 0.2 mm to +/- 0.4 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Thin-wall Injection Molding Materials

PP

Polypropylene finds large-scale use in thin-wall injection molding due to high flowability, chemical resistance, and lightness. Polypropylene is particularly favorable for cost-effective mass production of disposable plastic products. PP is used extensively in food packaging, medical packaging, and domestic items. For instance, containers for yogurt, take-away package, and syringe barrels are generally made from PP due to their light weight and strength.

- Mill Lead Time: Up to 5 days

- Color: White, translucent, or custom colors

PE

Polyethylene is rigid, tough, and chemically resistant and consequently highly suitable for a wide range of thin-wall uses. It is used in packaging, domestic consumer goods, and medical applications. PE is ubiquitous in squeeze bottles, flexible packs, and medical packing film. For instance, disposable specimen cups and soft drink covers utilize PE’s strength and flexibility.

- Mill Lead Time: Up to 5 days

- Color: Natural, white, or custom colors

PS

Polystyrene is a hard, transparent, and economical resin that can be easily processed and is extensively used in thin-wall injection molding. It is used in its end applications where high dimensional stability and transparency are critical. PS is extensively utilized in disposable tableware, CD boxes, and packaging trays. Transparent lids for food containers and light protection packaging materials often use PS to provide product visibility and integrity.

- Mill Lead Time: Up to 4 days

- Color: Clear, white, or custom colors

PVC

PVC is a very versatile plastic that is resistant to chemicals, strong, and cheap. It can be utilized both in rigid and flexible thin-wall applications. Common uses include medical tubing, blister packs, and electrical insulation. An example is that PVC is often used for clear packaging shells of electronics and medical-grade IV bags due to its high resistance and processability.

- Mill Lead Time: Up to 6 days

- Color: Clear, gray, or custom colors

ABS

Acrylonitrile Butadiene Styrene (ABS) is a general-purpose thermoplastic emulsion polymer. It has extensive use in automotive parts, toys, and electronic housings due to the good chemical resistance against corrosive chemicals.

ABS is easy to machine and has a low melting point, therefore making it extremely easy to mold and form. It also possesses high impact strength, meaning that it is extremely convenient to use in applications that must endure substantial stress or pressure. These features account for why ABS is utilised on a large scale all over the world in a number of sectors.

Common applications: Enclosures

PC

Polycarbonate is resistant to heat, impact, and clarity and is suitable for thin-wall parts that need to be clear and robust. It is applied in optical lenses, medical devices, and protective enclosures. For instance, protective eyewear, electronic display covers, and diffusers for LED lights benefit from PC’s excellent optical and strength properties.

- Mill Lead Time: Up to 4 days

- Color: Transparent, tinted, or custom colors

PA

Nylon is a tough, wear-resistant plastic that is widely utilized for mechanical and structural components in thin-wall injection molding. It has extensive usage in the automotive components market, electrical connectors, and industrial gear housings. Thin-wall gear covers, clips used on motor vehicles, and cable insulators, among others, utilize nylon due to its strength and long lifespan.

- Mill Lead Time: Up to 5 days

- Color: Natural, black, or custom colors

PET

Polyethylene Terephthalate is a very proper material for Thin-wall Injection Molding as it possesses a good strength-to-weight ratio, improved dimensional stability, and higher chemical resistance. Its high-temperature and pressure strength allows it to be able to create thin-walled, resistant parts that are light in weight. Food and liquid packaging containers, medical components, and consumer products are common uses. PET’s flexibility and good flowability ensure that it is best suited to make complex, high-precision components with thin profiles.

- Mill Lead Time: As fast as 7 days

- Color: Clear, Custom Colors Available

PEEK

PEEK is a high-temperature-resistant, high-strength product for critical use in aerospace, medical, and industrial components. It is used in lightweight structural parts, implantable medical applications, and aerospace insulators. For example, handles for surgical instruments, brackets for aircraft interiors, and high-temperature electrical enclosures rely on PEEK due to its high durability.

- Mill Lead Time: Up to 7 days

- Color: Natural beige, brown, or black

PPS

PPS is highly resistant to chemicals, heat, and mechanical stress, and hence it is suitably application in automotive, industrial, and electronic applications. It is seen widely used on fuel system components, high-temperature electrical enclosures, and precision sensors. Automotive connectors, pump housing, and circuit board components, for example, are made of PPS due to their shape retention capabilities over time and continued dependability.

- Mill Lead Time: Up to 6 days

- Color: Dark brown, gray, custom

LCP

LCP is of high strength, heat resistance, and thin-wall moldability, and hence well-suited for micro-components and electronic connectors. It is found in many smartphone housings, micro gears, and LED reflectors. Ultra-thin electronic casings and fine-pitch connectors, for example, use LCP to provide performance with optimal miniaturization.

- Mill Lead Time: Up to 5 days

- Color: Natural, black, custom

TPU

TPU is abrasion-resistant, elastic, and possesses excellent elasticity and is therefore best for protective shells, medical tubing, and shock components. Smartwatch bands, phone covers of soft touch, and elastic medical catheter tubes are some examples where TPU provides strength and comfort.

- Mill Lead Time: Up to 4 days

- Color: Transparent, black, custom colors

Finishing Options for Thin-wall Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Texturing (MT/VDI Standard) | ABS, PC, PP, POM | Matte, Satin | Injection Mold Tooling |

|

Polishing | PC, PMMA, ABS | High Gloss, Mirror Finish | Electroplating, UV Coating |

|

Silk-Screen Printing | ABS, PC, PP, POM | Custom Colors | Painting, Spray Coating |

|

Pad Printing | ABS, PC, POM, Nylon | Custom Colors | Painting, Spray Coating |

|

Laser Engraving | ABS, PC, Nylon | Black, Gray, White | Texturing, Polishing |

|

UV Coating | ABS, PC, PMMA | Glossy, Matte | Polishing, Painting |

|

Electroplating (Vacuum Metallization) | ABS, PC, PP | Chrome, Gold, Silver | Polishing, Texturing |

|

Painting & Spray Coating | ABS, PC, PP, POM | Custom Colors | Texturing, Polishing |

|

Hot Stamping | ABS, PC, PP | Gold, Silver, Metallic | Painting, Spray Coating |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Thin-wall Injection Molding Supplier Selection Ultimate Guide

Which thin-wall injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Thin-wall Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

When can I have my order delivered?

Lead times vary depending on the order size and complexity. Prototypes are 7-15 days, but production orders are 3-6 weeks. We’ll notify you of expedited production if necessary.

Can you help with mold design and modifications?

Yes! Our designers can assist with mold design, DFM analysis, and redesign to provide optimal performance and value.

What are standard tolerances for thin-wall parts?

Our standard tolerances are ±0.05mm, but tighter tolerances are available subject to material and design.

How costly is a thin-wall injection mold?

Mold prices depend on complexity of the part, size, and number of cavities. Simple mold begins at $3,000-$10,000, and mult-cavity molds for large quantities are more expensive. We quote competitive prices based on your needs.

Can I receive a sample before full production?

Yes, we can provide T1 samples for approval before going into mass production so that you can be confident the mold and part are to your specifications.

Do you have secondary assembly or packaging capabilities?

Yes, we can provide secondary services like ultrasonic welding, insert molding, and special packaging if desired.

Thin-wall Injection Molding Resource

Are You Looking for Thin-wall Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.