Custom Sheet Metal Molding Services

Formioo provides custom sheet metal molding services for prototypes and production parts, with as fast a 7-day turnaround, tight tolerances.

- More than 10 years of professional sheet metal manufacturing experience

- State-of-the-art manufacturing equipment such as laser cutting, bending, and pressing

- Economical for small batch and high-volume production

- 15+ Surface Finishing Solutions, including anodizing, powder coating, and plating

- Fast turnaround time of 7-12 days

Reliable Sheet Metal Molding Manufacturer from China

Formioo is a sheet metal molding services supplier for rapid prototyping and production. With in-house die fabrication, precision stamping equipment, and CNC bending/forming machines, we support fast turnaround on sheet metal parts with complex geometries and tight tolerances.

Our engineering team offers full DFM (Design for Manufacturability) support to help customers reduce design flaws, improve material utilization, and ensure forming feasibility. Whether you’re creating a bracket, housing, enclosure, or custom fixture, we help solve common issues such as warping, springback, or poor edge definition—ensuring each part meets both functional and visual requirements.

Since 2016, Formioo has delivered thousands of precision-formed sheet metal parts to clients across automotive, aerospace, electronics, medical devices, and industrial machinery sectors. Our flexible production capacity and fast prototyping services make us a reliable partner from early-stage development through to mid-scale manufacturing.

Our Sheet Metal Molding Services

Formioo offers a comprehensive range of sheet metal molding services, including laser cutting, CNC bending, precision stamping, and MIG/TIG welding. These processes enable us to manufacture custom brackets, housings, enclosures, panels, and structural components with high dimensional consistency and design flexibility. We work with a wide selection of metals such as aluminum, stainless steel, mild steel, galvanized steel, and copper to meet diverse mechanical and cosmetic requirements across different industries.

To meet both aesthetic and functional needs, we provide a variety of surface treatment options, including powder coating, anodizing, sandblasting, brushing, electroplating, and painting. Our sheet metal processes can typically achieve dimensional tolerances of ±0.1 mm, depending on material thickness, part geometry, and forming method. All parts are thoroughly inspected to ensure surface quality, edge accuracy, and structural integrity before delivery.

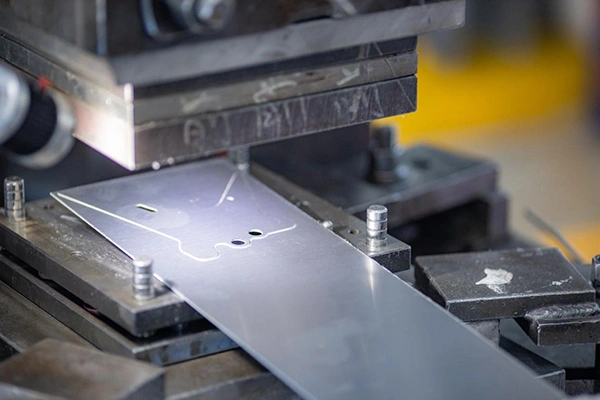

Laser cutting utilizes high-energy beams to precisely cut sheet metal into complex geometries without deformation.

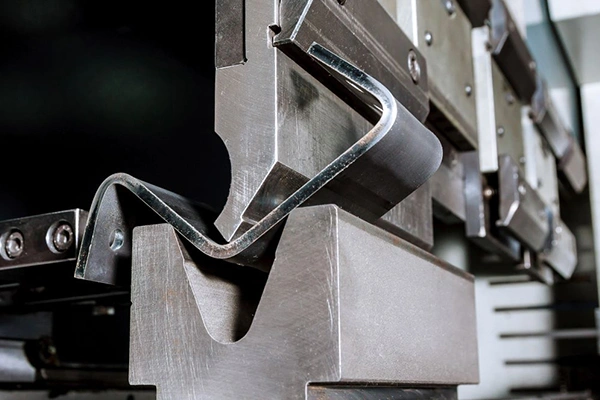

Bending shapes metal sheets into angular configurations under pressure, with accuracy and consistency in production.

Stamping makes use of dies and presses for producing intricate designs with high efficiency and reproducible quality in mass production.

Welding assembles metal sheets by heat and pressure, creating solid, long-lasting joints for complex assemblies.

Sheet Metal Molding Capabilities

Material Compatibility

We machine aluminum, stainless steel, brass, copper, and carbon steel to meet various industrial and custom manufacturing needs.

Machining Accuracy

Our standard tolerance is maintained within ±0.1mm, ensuring precision for mechanical and electronic components.

Maximum Build Size

Maximum print size in single 300mm × 300mm × 400mm, ideal for small and medium product or mold.

Surface Finishing Options

Painting, polishing, powder coating, and more available for extra durability and looks.

Delivery Time

7-12 days standard lead time, rush options for urgent projects.

Massive Network

We work with trusted sheet metal molding suppliers.

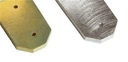

Explore Sheet Metal Molding Parts We Manufactured

Explore our high-quality sheet metal molded parts and see the precision for yourself. From prototyping to mass production, our expertly crafted components meet the highest industry standards.

Sheet Metal Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Sheet Metal Parts | +/- 0.5 mm to +/- 1.0 mm |

| High-Precision Sheet Metal Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Sheet Metal Parts | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Sheet Metal Molding Materials

Aluminum

Aluminum is being extensively employed in Sheet Metal Molding because it is lightweight, has good corrosion resistance, and a high strength-to-weight ratio. It can be easily cut, bent, and welded, thus being easily adaptable to different industrial applications. In the automobile industry, aluminum is being used for body panels, heat shields, and brackets. It is widely used in the electronics sector for enclosures and heat sinks because of its thermal conductivity. Aluminum is also used for aerospace structures to make lightweight yet high-strength components.

- Mill Lead Time: As fast as 3 days

- Finishes: Raw, anodized, powder coated, brushed, polished

Stainless steel

Stainless steel is Sheet Metal Molding’s preferred material due to its toughness, corrosion, and durability. It is applied in processes requiring toughness and resistance to wear. In the medical sector, stainless steel is found everywhere in enclosures, surgery equipment, and case hardware. Stainless steel finds applications in the food processing industry in hygienic equipment and kitchenware. Automotive and aerospace also rely on stainless steel for airplane structural components and brackets, and exhausts.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, brushed, polished, bead blasted, passivated

Carbon steel

Carbon steel is high in strength, low in cost, and simple to machine, which makes it an excellent Sheet Metal Molding material. It finds extensive applications in construction, industrial hardware for structure frames, mounting brackets, and enclosures. Carbon steel is used in body panels, reinforcements, and chassis parts in the automotive industry due to its high strength. Farm equipment and heavy equipment use the strength of carbon steel in applications for bearing stress.

- Mill Lead Time: As fast as 4 days

- Finishes: Raw, powder coated, painted, zinc-plated, black oxide

Brass

Brass succeeds in Sheet Metal Molding because of its excellent corrosion resistance, electrical conductivity, and good looks. Brass is most appropriate for embellishment metal components, architectural fittings, and musical instruments because of its golden appearance. For electronics, brass is most appropriate on connectors, terminals, and tiny components where there is a need for conductivity and non-magnetic qualities. Brass is also used in plumbing and marine commodities in the form of valves, fittings, and hardware because of its water corrosion resistance.

- Mill Lead Time: As fast as 6 days

- Finishes: Raw, polished, nickel-plated, chrome-plated

Copper

Copper is largely applied in Sheet Metal Molding owing to its corrosion resistance, malleability, and electrical and thermal conductivity. Copper is widely used in electrical fittings such as terminals, busbars, and heat exchangers. Copper is used on pipes and heat transfer equipment in HVAC applications. Copper is used by the automobile and aeronautical industries for radiators, heat sinks, and fuel lines because of their high thermal properties.

- Mill Lead Time: As fast as 5 days

- Finishes: Raw, polished, tin-plated, nickel-plated, patina finish

Finishing Options for Sheet Metal Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Powder Coating | Steel, Aluminum, Stainless Steel | Custom Colors | Spray Application |

|

Anodizing (Type II & III) | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Electroplating | Steel, Stainless Steel | Chrome, Gold, Silver | Electroplating Bath |

|

Polishing | Stainless Steel, Aluminum | — | Buffing, Tumbling |

|

Bead Blasting | Steel, Stainless Steel, Aluminum | — | Sandblasting, Abrasive Blasting |

|

Painting | Steel, Aluminum, Stainless Steel | Custom Colors | Spray, Dip, or Brush Application |

|

Laser Etching | Steel, Aluminum, Stainless Steel | — | Laser Machines |

|

Vibratory Finishing | Steel, Stainless Steel | — | Vibratory Tumbling |

|

Chromate Conversion Coating | Aluminum, Steel | Clear, Yellow | Chemical Coating Process |

|

Chem Film | Aluminum | Clear, Gold | Media Blasting, Tumbling, Anodizing |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Sheet Metal Molding Supplier Selection Ultimate Guide

Which sheet metal molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Sheet Metal Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What is your typical lead time on sheet metal components?

Lead times depend on part complexity and finishing requirements. Our typical orders are 7-15 days, but rush orders can be completed sooner.

Do you prototype before production in volume?

Yes, we do rapid prototyping so that your design is to spec before going into full production.

What is your cost model?

Pricing is material, complexity, quantity, and finishing-based. Send us your files, and we will respond with a 24-hour competitive quote.

Do you take low-volume or custom orders?

Absolutely! We specialize in both low-production volume and high-production volume manufacturing to suit your specific needs.

What file formats do you accept for quotes?

We take STEP, STP, DXF, DWG, PDF, and other typical CAD file types.

How do I place an order?

Simply upload your design files, discuss your material and finishing needs, and we’ll provide a fast quote and lead time.

Sheet Metal Molding Resource

Are You Looking for Sheet Metal Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.