Rapid Prototyping Service

- More than 10+ years of experience rapid prototyping

- Tight tolerance controllinto +/- 0.01mm

- 100+ Materials and various surface finishes

- Parts ship in 5-12 days

Reliable Rapid Prototyping Manufacturer from China

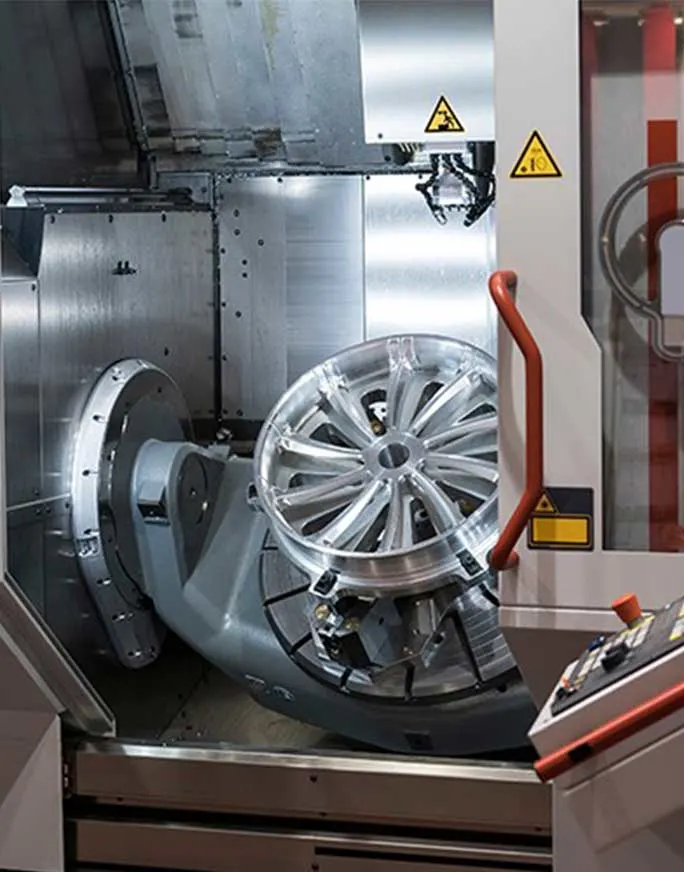

Formioo is a professional rapid prototyping manufacturer in China, offering rapid prototyping services for custom plastic parts with fast turnaround and high dimensional accuracy. With in-house rapid tooling, precision molding machines, and integrated CNC and 3D printing support, we can quickly turn your CAD designs into fully functional prototypes, typically within days.

Our rapid prototyping service is designed to help customers accelerate design validation, shorten development cycles, and avoid costly design errors. We offer DFM (Design for Manufacturability) feedback, material guidance, and support for complex part geometries such as thin walls, undercuts, and snap-fit features. Whether you’re testing assembly fit, surface quality, or end-use performance, we help you move from concept to part with speed and confidence.

Formioo produces thousands of prototype parts annually for companies in the automotive, medical, electronics, aerospace, and consumer product sectors. Our flexible production setup allows us to support everything from single-cavity short runs to low-volume bridge production—ensuring quality, consistency, and responsiveness at every stage of product development.

Rapid Prototyping in Multiple Materials

Formioo offers rapid prototyping services across a wide range of materials, including plastics, metals, and technical ceramics. Our capabilities span injection molding, CNC machining, vacuum casting, and industrial 3D printing, allowing us to produce high-quality prototypes for functional testing, fit validation, and market evaluation. We support common plastics like ABS, PC, PP, PA, and PEEK; metals such as aluminum, stainless steel, titanium, and copper alloys; and ceramic-based composites ideal for high-temperature or wear-resistant applications.

To meet both aesthetic and functional requirements, we provide various finishing options, including polishing, painting, anodizing, powder coating, bead blasting, electroplating, and silk screen printing. Depending on the process and material, we achieve tolerances as tight as ±0.01 mm for CNC-machined metal parts, ±0.05 mm for injection-molded plastic prototypes, and around ±0.1 mm for ceramic and additive-manufactured components. All parts are inspected using precision tools like CMMs and optical measuring systems to ensure dimensional integrity and repeatable quality.

Plastic Prototyping

Metal Prototyping

Ceramics Prototyping

Our Rapid Prototyping Features

Material Compatibility

Capable of printing PLA, ABS, PETG, Nylon (PA), TPU (flexible materials), and photosensitive resin, meeting various injection mold testing and product needs.

Printing Accuracy

Standard tolerance controlled within ±0.1mm, suitable for most industrial rapid prototyping and low-volume production.

Maximum Build Size

Single print size of up to 300mm × 300mm × 400mm, optimally for small to medium-sized products or molds.

Layer Thickness Range

Adjustable layer thickness, typically 0.1mm - 0.3mm, balancing printing speed and detail precision.

Delivery Time

Standard 3D printing delivery time is 2-5 days; complex structures may require longer. Expedited service is available.

Massive Network

We work with trusted rapid prototyping service suppliers.

Study Case of Our Prototyping?

Our Rapid Prototyping Capabilities

3D printing Prototyping

Our 3D printing rapid prototyping services are ideal for 3D printed plastics and metals, with extensive material and finishing options available. These additive manufacturing technologies can also sometimes be used for production.

Because 3D printing doesn’t require tooling, prototyping of 3D printed parts takes only a short time, without sacrificing build quality. Other advantages include geometrical freedom and affordability, especially in low volumes.

3D printing is often preferred for concept models, but precision technologies SLM can also work for functional prototypes and even production parts.

- FDM — Low-cost plastic parts prototyping

- SLA — Plastic parts prototyping with exceptional surface finish

- SLS —Strong prototyping parts in nylon or nylon glass

- SLM —Metal parts prototyping in steel or titanium

CNC Machining Prototyping

CNC machining is one of the most high-precision rapid prototyping technologies available. Although rapid CNC machining prioritizes short turnarounds over ultra-tight tolerances, the quality remains high.

Turnarounds are fast in low volumes, and CNC prototyping produces parts not too far from production quality. The cost is higher than 3D printing but the surface finish and part strength are often superior.

- CNC Milling — Milled prototype & production parts in plastic and metal

- CNC Turning — All types of round components

- CNC Grinding —Tight tolerance and good surface

- CNC EDM —For deep pocket & sharp conners.

Rapid Vacuum Casting

Rapid vacuum casting is a low-cost prototyping service for the production of low-cost plastic parts, particularly items like colorful display models.

Advantages of rapid vacuum casting include very low tooling costs compared to injection molding and a much lower minimum order quantity. And although vacuum cast parts are not especially durable, they come out of the mold with an excellent surface finish without post-processing.

The silicone mold used for rapid vacuum casting typically lasts around 20 shots, ideal for most prototyping scenarios.

- Rigid Plastics —Such as ABS, PC, PA simulate prototype parts

- Soft Rubber —Rubber like prototypes from Shore A 30 to 90 degrees.

- Wax —Patterns for low-vlume investment casting

Prototyping Tooling

Prototyping tooling for molding is ideal when the customer requires between 100–2,000 units of their injection molded parts; more than this and production-level steel tooling may be preferred.

Advantages of rapid tooling include fast turnarounds and the ability to carry out prototyping and testing of injection molded parts that might otherwise take months to produce. Rapid tooling is also significantly cheaper than mass production tooling.

Although rapid tooling and rapid injection molding is more expensive than 3D printing, it provides plastic parts much nearer to production quality that can therefore be used for functional testing.

- Plastic Injection Mold

- Die Casting Mold

- Extrusion Mold

Sheet Metal Prototyping

Rapid sheet metal prototyping is a set of rapid prototyping services for the production of sheet metal parts. This includes various forming, cutting, and assembly processes for manipulating the sheet metal stock in different ways.

Rapid sheet metal prototyping is generally used for flat parts like brackets and enclosures, and it can accommodate a range of sizes, including very large metal parts. Setup times can be longer than comparable processes, but sheet metal is highly cost-effective when making large and relatively simple parts.

An advantage of rapid sheet metal prototyping is that the solid sheet metal feedstock can later be CNC machined for additional features.

- Bending

- Stamping

- Welding

Metal Casting Prototyping

Casting is generally considered a production process for high-quality metal parts, but rapid metal casting — using 3D printing to make low-cost patterns — offers an affordable route for prototyping cast metal.

3ERP’s rapid metal casting services are only available due to our close relationship with several large casting companies which typically would not accept low-volume (10+) prototyping orders from new customers.

Advantages of rapid metal casting include near production-quality metal parts, with potentially very large sizes, at surprisingly fast speeds. Cast parts also have excellent tensile strength and can also be post-machined.

- Pressure Die Casting

- Investment Casting

- Gravity Casting

How it Works?

Quote Your Production

Our platform makes it easy to quote a large bill of materials at any quantity, across a wide range of processes and materials. Not ready to quote? Talk to our team for a free initial consultation.

Review Manufacturability Assessment

Our expert team of engineers will assess your designs and provide in-depth manufacturability feedback via our technology platform and in-person consultations.

Explore Cost-Down Opportunities

Based on your goals and target pricing, our strategic sourcing team will present suggestions and opportunities on how to remove cost from your bill of materials.

Production Begins

After the designs and sourcing plan are finalized, we will begin production using the most suitable manufacturing partner(s) for your program, assuming control of the schedule and quality at every phase.

Post-Processing and Assembly

Our platform makes it easy to quote a large bill of materials at any quantity, across a wide range of processes and materials. Not ready to quote? Talk to our team for a free initial consultation.

Packaging and Delivery

Our platform makes it easy to quote a large bill of materials at any quantity, across a wide range of processes and materials. Not ready to quote? Talk to our team for a free initial consultation.

Formioo Rapid Prototyping FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

How long does it take to get a prototype from Formioo?

The actual delivery time depends on the complexity and requirements of the project. Usually, we make every effort to complete the prototype within 3 days. We will negotiate a schedule with the client at the beginning of the project and strive to maintain efficient delivery.

What are the costs associated with Formioo prototyping service?

Our charges depend on the project complexity, size, and special requirements. We aim to offer economical services and publish open plans in the course of the initial consultations with our clients.

What types of materials work with your CNC machines?

Our instant quoted materials can be found here. Not seeing what you are looking for? You can always request a custom material through our custom RFQ process.

Is the customized pattern unique to us?

All designs will be kept secretly and confidential agreement can be signed.

Do you offer free samples?

Yes, free swatches and stock samples are free, but the shipping needs to be paid at customers side.

What file format do we use?

All is acceptable, including Ai, tif, jpg, psd, pdf.

Rapid Prototyping Resource

Are You Looking for Prototyping Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.