Prototypes Injection Molding Service

Formioo offers rapid injection molding services for producing high-quality plastic prototypes with production-grade precision. As fast as 7-day delivery.

- Functional testing of prototypes made from production-grade materials

- Tolerance as tight as ±0.01 mm

- Prototype injection molding parts 10,000+ per month

- More than 100 thermoplastics and thermosets

- Supports Injection Molding & Casting

Reliable Prototypes Injection Molding Services provider from China

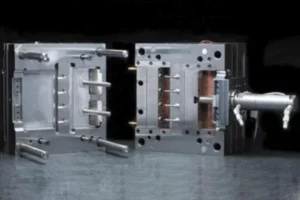

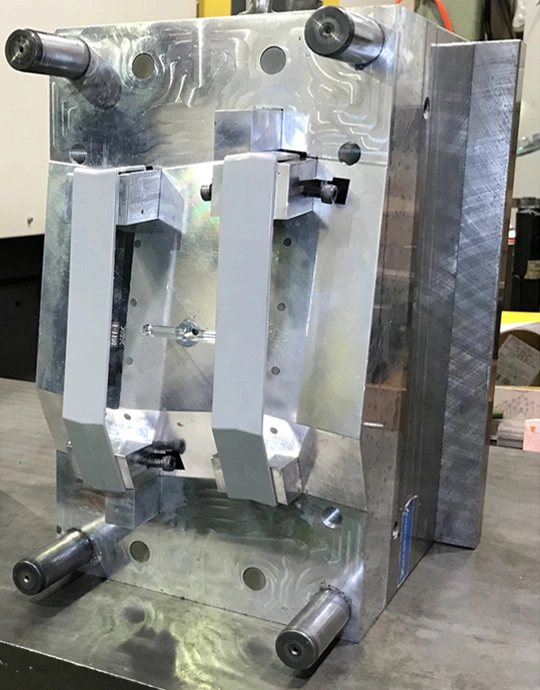

Formioo is a dedicated prototype injection molding manufacturer in China, specializing in low-volume, fast-turn plastic parts for design validation and functional testing. With in-house aluminum tooling, rapid mold fabrication, and precision injection machines, we deliver production-grade prototypes in as little as 7 days, ideal for bridging the gap between design and mass production.

Our service helps customers reduce development risks, shorten iteration cycles, and validate product performance before committing to full tooling investment. We offer DFM analysis, material consultation, and mold optimization to ensure every prototype accurately reflects final part quality, both visually and dimensionally.

With more than 10 years of experience in prototype injection molding manufacturing, Formioo produces thousands of prototype parts each year for industries including automotive, medical, electronics, consumer products, and industrial systems. We support batch sizes from 50 to 5,000 units with flexible lead times and consistent quality assurance from first shot to delivery.

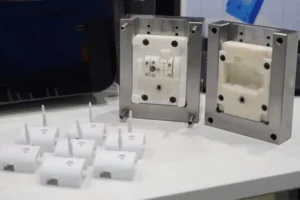

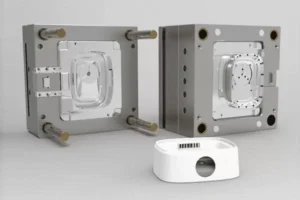

Prototypes Injection Mold & Parts We Manufactured

At Formioo, we specialize in producing a wide range of prototype injection molded parts, including functional housings, brackets, gears, enclosures, connectors, covers, and test-fit components. These prototype parts are often tailored for early-stage design validation, mechanical testing, and market evaluation across a wide array of applications, from vehicle components and medical housings to smart device enclosures and functional mechanical assemblies. We work with a wide selection of thermoplastics suitable for prototyping needs, including ABS, PC, PP, POM, Nylon, TPU, TPE, and filled materials like glass-reinforced nylon.

To enhance part aesthetics and functionality, we offer a variety of post-processing options, including sanding, polishing, painting, silk screen printing, vapor smoothing, and plating. Our prototype injection molds can achieve dimensional tolerances as tight as ±0.01 mm, depending on part complexity and material, ensuring that your parts closely replicate the final production version.

Prototypes Injection Molding Capabilities

Material Compatibility

We support general injection molding material like ABS, PP, PC, Nylon, POM, PEEK, and more, addressing diverse prototyping requirements.

Printing Accuracy

Our injection molding tolerance level is ±0.05mm, ideal for functional prototypes and small batch production in small numbers.

Maximum Build Size

We can injection mold as large as 800mm × 500mm × 300mm, which can accommodate most prototype needs.

Surface Finishing Options

We provide texturing, polishing, painting, pad printing, laser engraving, and other finishing methods for better aesthetics and functionality.

Delivery Time

Default prototype injection molding lead time is 7-14 days with additional options for faster lead time.

Massive Network

We work with trusted injection molding suppliers.

Explore Our Latest Prototype Injection Molded Parts

See the quality and precision of our injection-molded prototypes. Discover why leading companies trust Formioo for their prototyping needs.

Prototypes Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Prototypes | +/- 0.2 mm to +/- 0.5 mm |

| High-Precision Prototypes | +/- 0.05 mm to +/- 0.2 mm |

| Complex Prototypes | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Prototypes Injection Molding Materials

PP

PP (Polypropylene) is chemical-resistant, flexible, and cheap, the ideal material for most types of use in packaging, automotive parts, and household items. For instance, PP is common in food packets, bottle caps, and bumpers of cars because it’s hard and resistant.

- Mill Lead Time: Up to 5 days

- Color: Natural, white

PETG

PETG (Polyethylene Terephthalate Glycol) is chemical resistant, rigid, and transparent and is ideal for functional prototypes and end-use products. PETG is applied widely in medical devices, food packaging, and showcase cases. PETG, for example, is normally applied for medical device enclosures due to its rigidity and transparency.

- Mill Lead Time: Up to 4 days

- Color: Clear, black, white

PLA

PLA (Polylactic Acid) is biodegradable plastic and is used in prototyping and low-stress applications. It has low molding temperature and gives a smooth finish surface. It is suitable for disposable packaging, consumer items, and educational prototypes. For instance, PLA is used extensively in food packets and 3D-printed prototypes.

- Mill Lead Time: Up to 2 days

- Color: White, translucent

ABS

ABS (Acrylonitrile-Butadiene-Styrene) is one of the injection molding materials of choice due to the fact that it possesses adequate mechanical strength, impact strength, and processibility. It is applied in a wide variety of products ranging from automotive trim, electronic enclosures, and household items to car dashboards and toy parts, for example. The reason being its hardness and finish.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PC

PC (Polycarbonate) is incredibly strong, clear polymer with great impact-resistance and consequently applied in protective gear, lenses, and electronics. For instance, PC is largely applied in protecting eyeglasses, phone covers, and automobile headlights due to its hardness and transparency.

- Mill Lead Time: Up to 6 days

- Color: Clear, black

PA

Nylon (Polyamide) is equally wear-resistant, hard, and elastic and thus utilized in gears, bearings, and structure components. Nylon is commonly used in the industrial and vehicle industry. Nylon, for example, will normally be used in gears as well as in sliding components printed using 3D printing since it is of low friction and high resistance.

- Mill Lead Time: Up to 5 days

- Color: Natural, black

POM

POM (Polyoxymethylene) is a hard, low-friction plastic well adapted for precision parts such as bearings, gears, and fasteners. POM is extremely commonly used in mechanical engineering, not to mention the automotive industry. POM, for example, is extremely commonly used in 3D-printed gears due to wear and dimensional stability.

- Mill Lead Time: Up to 4 days

- Color: White, black

PEEK

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic with superior mechanical properties, chemical resistance, and thermal stability. PEEK is employed in aerospace, medical implants, and industrial parts. For example, PEEK is applied in 3D-printed aerospace components due to its thermal and strength stability.

- Mill Lead Time: Up to 7 days

- Color: Natural, black

PPS

PPS (Polyphenylene Sulfide) is extremely durable, chemical resistant, and heat resistant, thus qualified for application in automobile and electrical use. For instance, PPS has extensive application in 3D-printed fuel system components and electrical connectors.

- Mill Lead Time: Up to 7 days

- Color: Natural, black

PVDF

PVDF material (chemical designation Polyvinylidene fluoride) is processed by Ensinger into standard product form as sheets and rods. Polyvinylidene fluoride is a semi-crystalline, opaque, thermoplastic fluoropolymer. PVDF is exceptionally adept at chemical resistance without low mechanical values and/or processing problems that are typically characteristic of other fluoropolymer materials. 171 degrees Celsius is the melting point for PVDF material.

Finishing Options for Prototypes Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum | Clear, gold | Media Blasting, Tumbling, Anodizing |

|

Anodizing | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Powder Coating | Aluminum, Steel, Plastic | Wide Range of Colors | Spray Application |

|

Polishing | Aluminum, Stainless Steel | — | Buffing, Tumbling |

|

Laser Etching | Aluminum, Steel, Plastic | — | Laser Machines |

|

Electroplating | Steel, Copper, Zinc | Gold, Silver, Chrome | Electroplating Bath |

|

Silk Screening | Plastic | Multiple | Manual or Automated Process |

|

Vibratory Finishing | Aluminum, Stainless Steel | — | Vibratory Tumbling |

|

Chrome Plating | Steel, Brass, Aluminum | Chrome | Electroplating Bath |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Prototypes Injection Molding Supplier Selection Ultimate Guide

Which prototype injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Prototypes Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What is your typical lead time for prototype injection molding?

Typically 7-14 days, although we can do emergency work on rush projects.

Do you have a minimum order quantity (MOQ)?

No MOQ—you can order even just a single prototype.

Can you provide surface finishing on prototype parts?

Yes, we offer finishes like texturing, painting, and polishing, and so on.

Is prototype tooling reusable for mass production later?

Prototype molds are usually for short runs, but in case of need, we can create tooling for higher volume production.

How quickly can I receive a quotation?

You’ll usually get your quotation within 24 hours.

Can I request design revisions after molding has started?

Minor revisions might be possible, but we recommend finalizing designs before tooling.

Prototypes Injection Molding Resource

Are You Looking for Prototypes Injection MoldingManufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.