Custom Plastic Molding Prototype Service

Formioo provides rapid plastic molding prototype services to help you validate designs faster, with quick tooling, material flexibility, and production-grade quality.

- 10+ years of plastic molding prototype experience

- Design for Manufacturability (DFM)

- Material in wide range, e.g., ABS, PC, PP, etc.

- In-process CMM inspection and machine monitoring

- 24/7 engineering support

Reliable Plastic Molding Prototype Manufacturer from China

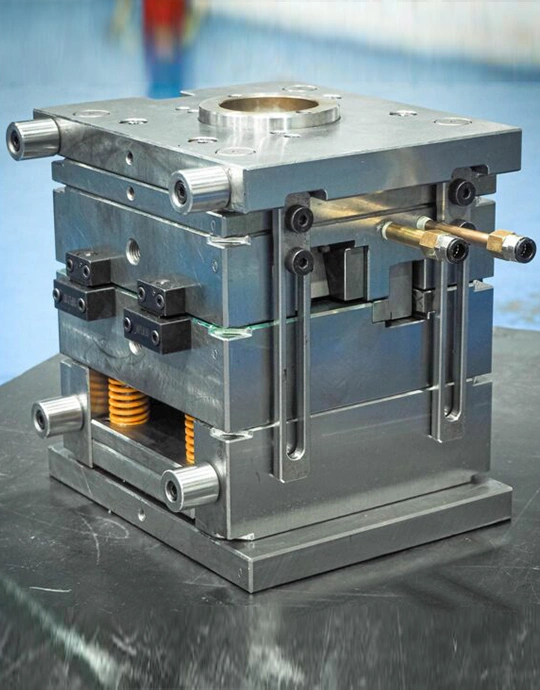

Formioo is a rapid plastic molding prototype services provider to help customers accelerate product development and design validation. With in-house mold design, quick-turn tooling, and a range of molding processes, including injection, blow, and compression molding, we help customers turn 3D concepts into physical parts within days, accelerating early-stage development and functional testing.

Our team provides detailed DFM (Design for Manufacturability) analysis and hands-on engineering support to help clients reduce design flaws, optimize part geometry, and ensure material compatibility. Whether you’re validating fit, function, or surface aesthetics, we help solve common challenges such as warping, shrinkage, draft issues, and tooling defects, ensuring your prototype is ready for scale-up.

Since 2016, Formioo has produced thousands of custom plastic prototypes for companies in automotive, medical devices, consumer electronics, industrial equipment, and packaging sectors. Our flexible MOQ, short lead times, and production-grade quality make us a trusted partner for startups, engineers, and product teams bringing new ideas to market.

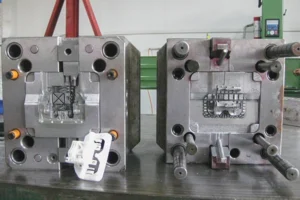

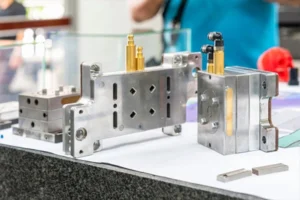

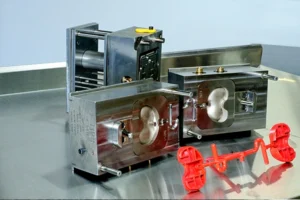

Plastic Molding Prototype & Parts We Manufactured

Formioo produces a wide variety of plastic molding prototypes and end-use parts, including enclosures, housings, brackets, connectors, caps, handles, packaging components, and custom functional assemblies. These parts are used across industries such as automotive, electronics, medical devices, and consumer products. We support a broad selection of prototyping materials, including ABS, PC, PP, PE, PA, POM, TPU, and high-performance plastics like PEEK and PPSU, allowing customers to test real-world function, fit, and durability with production-equivalent properties.

To support different design goals and product stages, we offer multiple molding technologies such as rapid injection molding, blow molding, compression molding, and insert molding. Surface finishing options include texturing, polishing, ultrasonic welding, pad printing, painting, and vapor polishing for transparent parts. Our prototype processes can achieve typical tolerances of ±0.1 mm to ±0.3 mm, and all parts are carefully inspected to ensure dimensional accuracy, visual quality, and manufacturability for scaling.

Plastic Molding Prototype Capabilities

Material Compatibility

We provide compatibility with various materials such as ABS, PC, PP, Nylon, and others to suit different prototyping and production requirements.

Printing Accuracy

We offer high-accuracy molding with close tolerances, providing consistent quality for applications with stringent requirements.

Maximum Build Size

We offer molding assistance with parts measuring up to 500mm × 400mm × 300mm, accommodating various sizes of projects.

Surface Finishing Options

We offer polishing, painting, texturing, and other finishes to enhance aesthetics and functionality.

Delivery Time

Our standard turnaround is 7-14 days, with rush service for projects with time constraints.

Massive Network

We work with trusted plastic molding prototype suppliers.

Discover Our Latest Plastic Molding Prototype Products

Explore our plastic molding prototype and see the quality for yourself. From rapid prototyping to low-volume production, our components meet the toughest industry standards. Visit Formioo to view our latest projects and learn how we can bring your designs to life with speed and precision.

Plastic Molding Prototype Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Plastic Prototypes | +/- 0.3 mm to +/- 0.6 mm |

| High-Precision Plastic Prototypes | +/- 0.1 mm to +/- 0.3 mm |

| Complex Plastic Prototypes | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Plastic Molding Prototype Materials

PP

Polypropylene (PP) is a general purpose commodity plastic, and it is highly suitable for prototypes injection molding due to its excellent chemical resistance, fatigue resistance, and low density. It is excellent at producing robust components with smooth surfaces and is a popular choice for gears, snap-fit components, and cosmetic housings. Its rapid cooling characteristics and repeatability enable fast production of functional prototypes. PP exhibits excellent performance on intricate designs and sophisticated geometries, and it also allows for keeping very high levels of accuracy for all injection molded components.

- Mill Lead Time: 3-5 days

- Color: Translucent, gray

PE

Polyethylene (PE) finds its optimal application in prototypes injection molding due to the fact that it is highly resistant to chemicals, easy to process, and cost-effective. Its impact strength and flexibility render it suitable for the production of containers, protective covers, and light structural components. PE in prototyping has widespread uses in the production of disposable products, packaging material, and water-sealed enclosures. Its quick processing and good dimensional stability allow rapid iterations. The simplicity and versatility of PE enable the achievement of complex designs, and it is a good material for early development.

- Mill Lead Time: 2-4 days

- Color: Natural, white

PS

Polystyrene (PS) is a low-cost and easy-to-process commodity plastic, making it a suitable material for prototypes injection molding. It possesses very good clarity and rigidity, making it ideal for model part making, display fixtures, and consumer product prototypes. PS’s capability of getting a good surface finish and detail accuracy allow designers to quickly develop and refine their ideas. Relative dimensional stability and low water absorbency of the material also provide assurance that it can deliver precise and consistent prototypes even with complex geometry.

- Mill Lead Time: 1-3 days

- Color: Clear, various

PVC

Polyvinyl Chloride or PVC is one of the commodity plastics that is durable, versatile, and commonly applied because of ease in prototype injection molding. Its resistance to environmental breakdown, chemicals, and burning make it one of the best materials for such prototypes like fittings, pipes, and insulated items. PVC is well suited to complicated mold design with high rigidity and tensile strength. Its cost effectiveness and low production time allow designers to rapidly test and manufacture products, so it is a regular material used in most industrial and consumer products.

- Mill Lead Time: 4-6 days

- Color: Off-white, gray

PC

Polycarbonate (PC) is a suitable engineering plastic for prototype injection molding because of its impact strength, translucency, and heat stability. Its characteristic strength-to-lightness ratio allows the generation of strong prototypes like light housings, protective covers, and medical device parts. PC can withstand severe stress and temperature cycling so that prototypes are highly similar to end-product performance. Its precision in molding can be employed to produce high-accuracy complex geometries, providing designers good, high-fidelity prototypes.

- Mill Lead Time: 3-5 days

- Color: Transparent, blue-tinted

PA

Nylon (PA) is a tough, impact, abrasion-resistant injection molding engineering plastic. Nylon is ideally used for functional prototypes with high mechanical properties, e.g., gears, bearings, and moving parts. High durability and low friction of Nylon allow prototypes to accurately represent actual operating conditions in the field with good repeatability. Its better resistance to repetitive stress and temperature fluctuation makes it the ideal choice for dynamic applications, and its ability to precisely generate intricate geometries makes it extremely detail-intensive in use.

- Mill Lead Time: 2-4 days

- Color: Natural, off-white

POM

Polyoxymethylene or POM is an engineering plastic that exhibits good dimensional stability with low friction properties in prototype injection molding. POM rigidity and abrasion resistance are ideal for precise parts such as bearings, gears, and valve parts. The fact that POM can maintain close tolerances and exhibit reproducible performance on repeated motion guarantees that prototypes accurately represent end product performance. Easy processing of the material and a smooth surface make designers able to create accurate models rapidly, a reason why it is an appropriate material for high-quality prototype manufacturing.

- Mill Lead Time: 3-5 days

- Color: Gray, natural finish

PEEK

Polyetheretherketone (PEEK) is an elite high-performance plastic injection prototyping molding for high-demand applications. It has excellent chemical resistance, mechanical strength, and heat stability, making it an ideal candidate for aerospace components, medical implants, and high-stress engineering components. PEEK’s properties are retained even under severe temperatures and corrosive chemicals, thus the prototypes are true representations of end products. Its dimensional stability and wear resistance enable the reproduction of complex designs accurately. This material offers excellent performance for prototype critical testing, bridging concept to production with confidence.

- Mill Lead Time: 5-7 days

- Color: Natural, off-white

LCP

Liquid Crystal Polymer (LCP) is a high-performance plastic with superior prototype injection molding performance characterized by greater thermal stability, strength, and chemical resistance. LCP finds extensive use in prototype connector manufacturing, electronic components, and high-frequency communication equipment production. LCP’s unique molecular structure enables one to shape intricate and detailed geometries within a brief time with minimal shrinkage and high reproducibility. Its high performance in extreme environments makes it appropriate for precision engineering models that also require high toughness so that accurate and repeatable testing is possible.

- Mill Lead Time: 5-7 days

- Color: Black, matte finish

PAEK

PAEK (Polyaryletherketone) is a performance engineering plastic with excellent strength, thermal stability, and resistance to chemicals, which is suitable for prototyping injection mold of highly demanding applications. Its excellent features allow prototypes with superior mechanical performance to be manufactured, such as aerospace components, medical implants, and parts of industrial equipment. PAEK maintains its structural integrity at extreme temperatures and severe chemical environments. Its high-temperature molding ability permits complex, high-tolerance geometry very close to the final part, offering beneficial design input to product design.

- Mill Lead Time: 7-10 days

- Color: Customizable, varied

PI

Polyimide (PI) is a heat-resistant plastic with superior heat resistance and mechanical properties, and it is a best choice for prototype injection molding for high-temperature use. It is used extensively in prototype electronic parts, automotive components, and industrial seal manufacturing. PI resists high temperature exposure for long periods and corrosive environments, allowing prototypes to withstand structure and function under hostile testing. It is dimensionally stable to a very high degree and has accurate moldability, so it can be used to create very complicated, highly detailed models close to the end product.

- Mill Lead Time: 6-8 days

- Color: Amber, semi-gloss

Finishing Options for Plastic Molding Prototype

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Plastic, Resin | — | Buffing, Tumbling |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Painting | Plastic | Custom Colors | Spray, Dip, or Brush Application |

|

UV Coating | Plastic | Glossy, Matte | UV Curing Process |

|

Laser Etching | Plastic, Resin | — | Laser Machines |

|

Powder Coating | Plastic, Metal | Custom Colors | Spray Application |

|

Bead Blasting | Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

Silk Screening | Plastic | Multiple | Manual or Automated Process |

|

Surface Texturing | Plastic, Resin | — | Mold Texturing, Laser Etching |

|

Vibratory Finishing | Plastic, Metal | — | Vibratory Tumbling |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Plastic Molding Prototype Supplier Selection Ultimate Guide

Which plastic molding prototype supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Plastic Molding Prototype FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

How long does it take you to create a prototype?

We offer rapid prototyping with lead times ranging as low as 1-2 weeks so you can quickly go from concept to test.

Minimum order quantity (MOQ) for prototypes?

No MOQ! We’re set up to produce as few as 1-10 parts, so you can test and refine your design without investing too much.

Can you help with design optimization?

Yes, we can verify your design to be manufactured using our engineering team, and you enjoy time and cost savings during production.

Do you scale up from prototyping to production?

Absolutely! We offer seamless transition to production molding so that you can move from prototype to high-volume production with ease.

Can you handle complex geometries?

Yes, we specialize in complex design and tight tolerances so that you can prototype even the most challenging parts.

Do you offer overmolding or multi-material prototypes?

Absolutely! We provide overmolding and multi-material options to test complex assemblies or soft-touch features.

Plastic Molding Prototype Resource

Are You Looking for Plastic Molding Prototype Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.