Custom Plastic Extrusion Molding Services

Formioo provides custom plastic extrusion services for a wide range of profiles, tubes and complex shapes, offering flexible material selection and fast 7-day delivery time.

- Easily upload your CAD file and get a free quote

- Different material options, like ABS, PVC, and Polycarbonate

- Tolerance within 0.01mm

- 24/7 engineering support

Reliable Plastic Extrusion Molding Service Provider from China

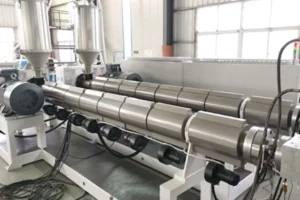

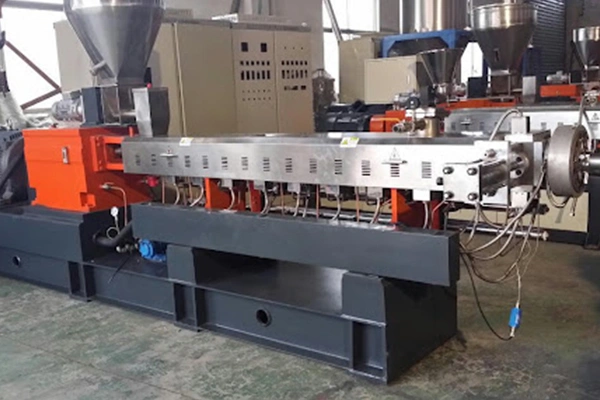

Formioo is a China-based injection molding manufacturer providing custom plastic extrusion molding services for a wide variety of profiles, tubes, and continuous cross-sectional parts. With in-house die fabrication, precision-controlled extrusion lines, and rapid tooling support, we help clients move quickly from concept to functional prototypes with consistent quality and fast lead times.

Our extrusion services focus on delivering clean surface finishes, accurate dimensions, and long-length stability across complex shapes. We offer expert DFM (Design for Manufacturability) feedback to help clients solve challenges such as warping, shrinkage, and thickness variation. Whether you’re developing a flexible channel or a rigid profile, our team ensures high repeatability and process control from the first meter to the last.

With over 10 years of manufacturing experience, Formioo produces thousands of custom extruded parts monthly for customers in construction, automotive, consumer electronics, medical devices, and industrial enclosures. We support both small-batch runs and long-term production needs, providing flexibility, responsiveness, and dependable supply for a wide range of applications.

Our Plastic Extrusion Molding Services

Formioo offers a full suite of plastic extrusion molding solutions, including single-screw extrusion for standard profile production, twin-screw extrusion for enhanced material mixing and processing stability, co-extrusion for multi-material or multi-color layering, and precision Profile Extrusion for custom cross-sectional designs. These technologies allow us to produce complex profiles, tubes, and channels with consistent quality and long-length accuracy. We support a wide range of thermoplastic materials, including PVC, PE, PP, ABS, PC, and TPU, to meet various structural, optical, or flexible product requirements.

To meet different performance and aesthetic needs, we offer a range of post-extrusion finishing options such as cutting, drilling, punching, embossing, and surface texturing. Our extrusion processes can achieve typical tolerances of ±0.15 mm for standard profiles, and down to ±0.1 mm for more controlled geometries, depending on material type and wall thickness. All extruded parts undergo dimensional checks and surface inspection to ensure consistency and conformance with client specifications.

Continuous process for uniform thermoplastic profiles.

Enhanced mixing and processing of complex materials.

Multi-layer extrusion for advanced material properties.

Custom-shaped profiles for diverse industrial applications.

Plastic Extrusion Molding Capabilities

Material Compatibility

ABS, PVC, Polycarbonate, Polyethylene, and others, tailored for various industrial uses.

Printing Accuracy

Consistent precision to meet high-performance requirements.

Maximum Build Size

Maximum size of 2000mm to accommodate large project sizes.

Surface Finishing Options

Polishing, sandblasting, painting, and UV coating for higher durability and aesthetic value.

Delivery Time

Standard lead time of 7-14 days with expedited service on urgent orders.

Massive Network

We work with trusted plastic extrusion molding suppliers.

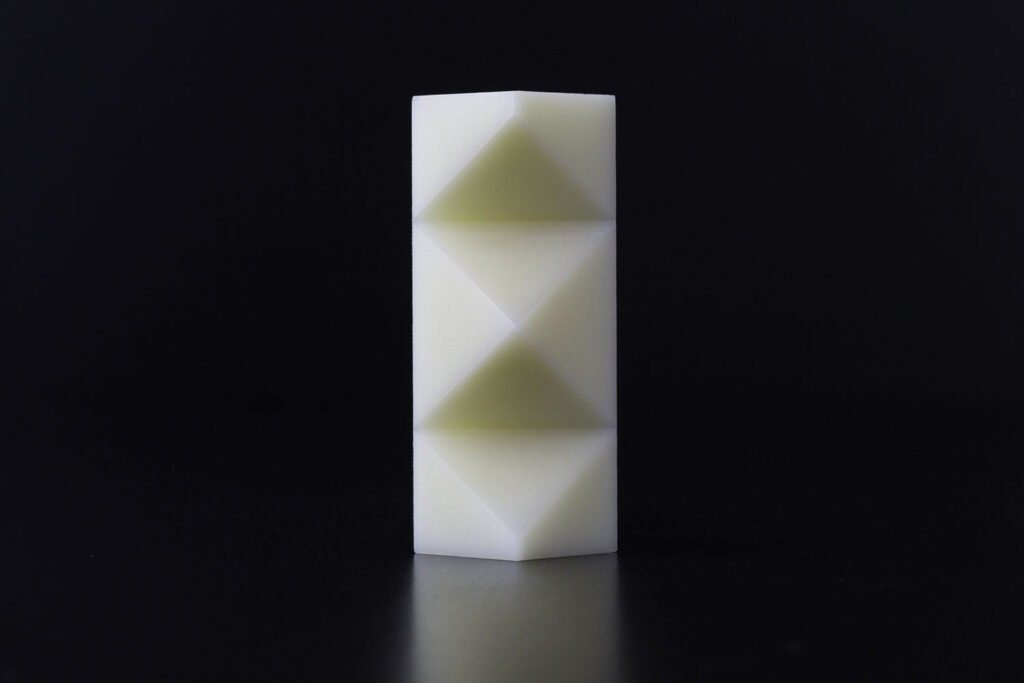

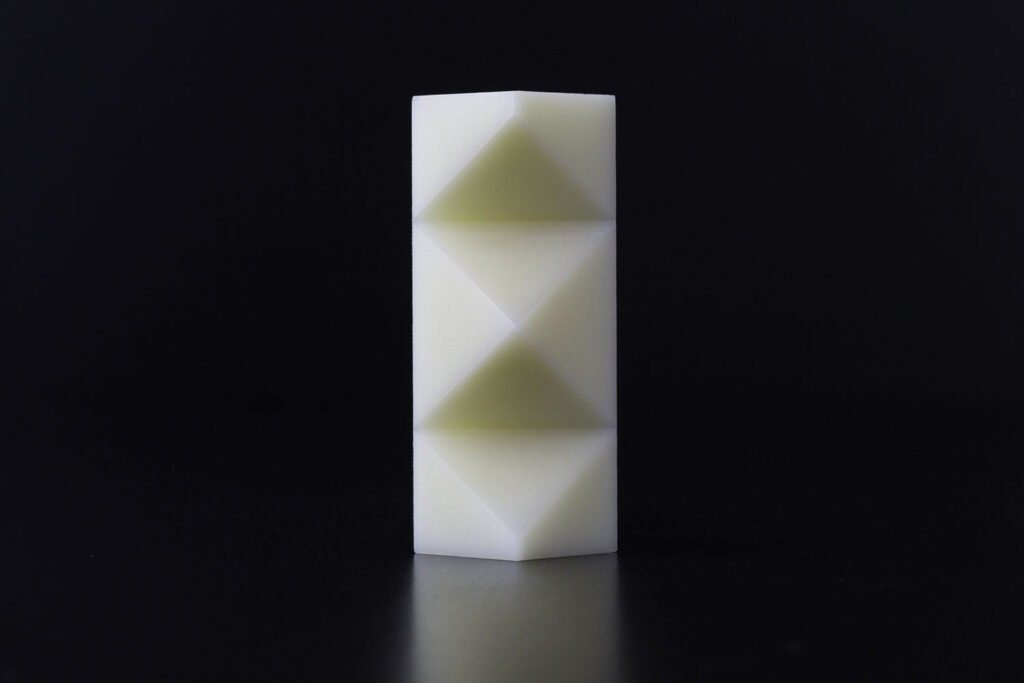

Explore Plastic Extrusion Molding Parts We Manufactured

Our complete plastic extrusion molding service will accompany your plastic extrusion molding project from the prototype construction to the end plastic parts manufacturing.

Plastic Extrusion Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Extrusion Parts | +/- 0.5 mm to +/- 1.0 mm |

| Precision Extrusion Parts | +/- 0.2 mm to +/- 0.5 mm |

| Complex Extrusion Parts | +/- 0.3 mm to +/- 0.8 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Plastic Extrusion Molding Materials

PP

Polypropylene offers a combination of chemical resistance, rigidity, and good melt flow properties, and hence it is extremely well suited for extrusion molding. Its versatility is seen in the range of uses such as automotive parts, household containers, and plumbing. Extruded PP, for instance, is used to make living hinges, profiles for insulation, and cable jackets. Sustainability in various environments and low cost with high productivity serve to maximize its popularity in commercial and industrial markets.

- Mill Lead Time: 3-4 days

- Color: Translucent, opaque, or vibrant hues

PE

Polyethylene is the most widely used plastic for plastic extrusion molding due to its favorable flow characteristics, resistance to chemicals, and easy processing. Its stable melting behavior enables smooth-profile products to be made and makes it ideal for making pipes, films, and sheets. For example, HDPE is widely used in the manufacturing of heavy-duty water pipe and geomembranes, and LDPE in flexible packaging and farm film. With its low cost and versatility, the material is suitable for application in consumer and industrial goods.

- Mill Lead Time: 2-3 days

- Color: Natural, white, or customized

PS

Polystyrene is similarly preferred for extrusion molding because of its processability, cost effectiveness, and capacity for producing smooth, uniform profiles. Its hardness makes it especially suited for the production of items like laboratory equipment, food packaging, and disposable forks and knives. PS extrusions are similarly extensively utilized for the production of insulation panels and trim for ornamental purposes. Reproducibility in molding provides high dimensional stability, an essential function in applications where accurate tolerances and aesthetic finish are required.

- Mill Lead Time: 2 days

- Color: Clear, white, or custom color options

PVC

PVC has long been known to be more durable, weatherproof, and easily processable for extrusion application. PVC is very commonly used in the manufacturing of pipes, window frames, and cable insulation due to its robust chemical resistance and low maintenance requirements. PVC extrusions are also used in making siding, flooring, and various industrial profiles. Its flexibility to use additives also enhances its performance across a broad spectrum of environmental conditions to be the material of preference for long-lasting outdoor and indoor applications.

- Mill Lead Time: 3 days

- Color: White, grey, or custom shades

PC

Polycarbonate is appreciated in extrusion molding owing to its impact resistance, optical clarity, and stability of dimensions. Good flow characteristics allow it to be employed in the production of protective shields, lighting diffusers, and fine-profiled electronic components. In greenhouse panel, machine guard, and protective enclosure production, for instance, PC extrusions are frequently used. Its resistance to stress and temperature changes allow it to withstand severe industrial and consumer environments.

- Mill Lead Time: 4 days

- Color: Clear, amber, or custom tinted

PA

Nylon is commonly utilized as an engineering plastic for extrusion due to its good strength, exceptional abrasion, and low friction properties. It is commonly extruded into extremely strong profiles such as gears, bearings, and tubing for fluid transfer purposes. Nylon extrusions are found in everyday applications in the form of vehicle parts, electrical conduits, and components of industrial machinery. Its heat resistance as well as mechanical strength guarantee one-way operation under varying loads and temperatures and are therefore a precious material in precision engineering.

- Mill Lead Time: 3-5 days

- Color: Natural, off-white, or customized

POM

Acetal or polyoxymethylene (POM) is highly appreciated due to its high frictional property and dimensional stability, and is therefore one of the most sought materials used in extrusion molding. It can be optimally utilized to create precision extrusions that find application in seals, gears, and other mechanical parts. For example, extruded acetal profiles are employed in automotive fuel systems, industrial rollers, and consumer device components. Its reliability in performance under repeated stress and protection against moisture and solvents point to its central importance in uses where tight tolerances and long-term constancy are necessities.

- Mill Lead Time: 3 days

- Color: Natural, white, or custom blended

PEEK

PEEK is a high-performance thermoplastic extensively recognized for its outstanding mechanical properties, chemical resistance, as well as its resistance to high temperatures, making it a strong contender for extrusion molding in high-performance applications. It is generally utilized to fabricate advanced profiles for aerospace equipment, medical devices, and high-pressure piping use. For example, PEEK extrusions are applied in pump housings, valve components, and connectors with harsh environments. Its wear and fatigue resistance and hard environment strength make it the optimal selection in high-performance, long-life materials required by industries.

- Mill Lead Time: 5-7 days

- Color: Natural, black, or specialized hues

PPS

PPS is also valued due to its high chemical resistance, dimension stability, and thermal stability during extrusion molding. Its properties highly recommend it for the manufacture of parts in harsh chemicals, including pump casings, under-the-hood automotive components, and electric connectors. PPS extruded profiles are employed in those applications where uniform performance at high temperature and under harsh chemicals is required. Its low moisture absorption and fatigue resistance give long-term stability and safety for significant applications, thereby increasing the life and performance of the product.

- Mill Lead Time: 4-6 days

- Color: Gray, natural, or specified by client

PEI

PEI is a high-performance plastic that, due to its excellent heat resistance, dimensional stability, and electrical properties, is of immense application in extrusion molding. It is used in demanding applications such as medical device parts, interior components of aerospace, and high-temperature piping systems. For example, PEI profiles extruded find applications in making electrical insulators, structural supports, and precision connectors. Its inherent flame retardation and resistance to loss of strength under prolonged stress make it an excellent product for advanced engineering and mission-critical industrial use.

- Mill Lead Time: 5 days

- Color: Translucent, white, or client-specific

PI

Polyimide is characterized after extrusion molding because of its thermal stability, electrical insulation, and excellent chemical resistance. This high-strength plastic is employed in the production of components that are required to endure severe temperatures, including aircraft insulation, electrical wire coatings, and advanced composite components. In real-world applications, PI extrusions are employed to encapsulate sensors, flexible printed wiring, and essential seals. Its specific capability for withstanding steady performance in high-stress, high-temperature conditions renders it a top material selection for state-of-the-art engineering projects.

- Mill Lead Time: 7-10 days

- Color: Amber, brown, or custom engineered

Finishing Options for Plastic Extrusion Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Plastic | — | Buffing, Tumbling |

|

Painting | Plastic, Rubber | Custom Colors | Spray, Dip, or Brush Application |

|

UV Coating | Plastic, Rubber | Glossy, Matte | UV Curing Process |

|

Anodizing | Aluminum, Plastic | Clear, Black, Gold | Media Blasting, Tumbling, Anodizing |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Bead Blasting | Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

Surface Texturing | Plastic | — | Mold Texturing, Laser Etching |

|

Laser Etching | Plastic, Metal | — | Laser Machines |

|

Vibratory Finishing | Plastic | — | Vibratory Tumbling |

|

Extrusion Coating | Plastic | Custom Colors | Extrusion Coating Process |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Plastic Extrusion Molding Supplier Selection Ultimate Guide

Which plastic extrusion molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Plastic Extrusion Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What’s your lead time for extrusion projects?

Our standard lead time is 4-6 weeks, but we have rush capabilities for urgent orders to keep you on schedule.

Do you extrude multi-layer or co-extruded profiles?

Yes! We have multi-layer and co-extrusion capabilities to blend materials to achieve higher performance.

How much is your minimum order quantity (MOQ)?

Our MOQ is flexible, and we can handle low and high-volume production runs to meet your needs.

How do you guarantee quality in extrusion molding?

We employ sophisticated quality control techniques and subject our products to rigorous testing, so you get consistent, high-quality products every time.

Do you extrude UV-stable or flame-retardant materials?

Yes, we offer special materials with UV stability, flame retardation, and other values to meet your own needs.

Do you extrude multi-layer or co-extruded profiles?

Yes, we can perform multi-layer and co-extrusion services to mix materials for better performance.

Plastic Extrusion Molding Resource

Are You Looking for Plastic Extrusion Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.