Low-Volume Manufacturing Service

Formioo offers low-volume manufacturing services for custom plastic and metal parts across prototyping and bridge production stages. Prototype design can be completed in as little as two days.

- Rapidly-made in a few days

- Fast turnaround

- 100 to 100,000+ metal and plastic parts

- More than 10+ years experience of low-volume manufacturing

One-stop Solution Provider for All Your Low-Volume Part Production

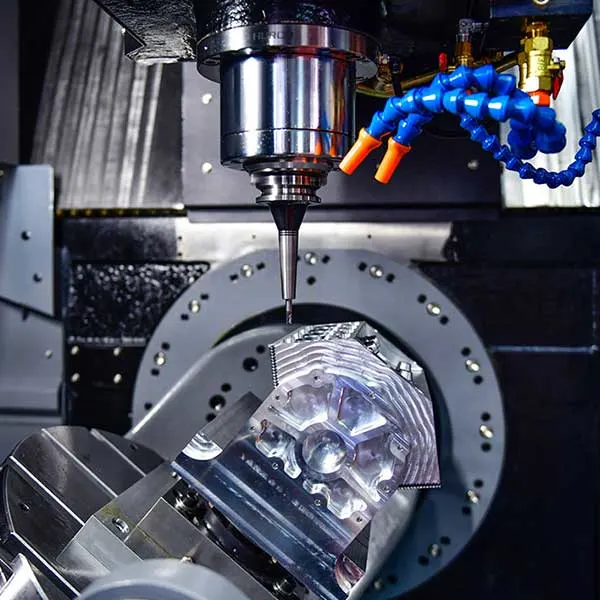

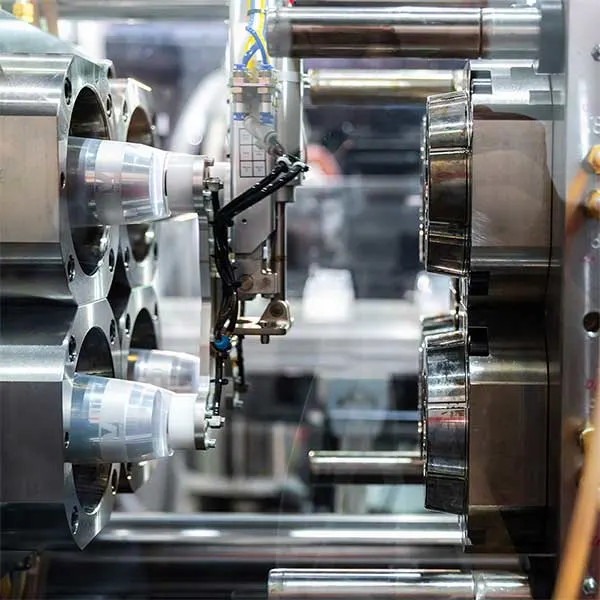

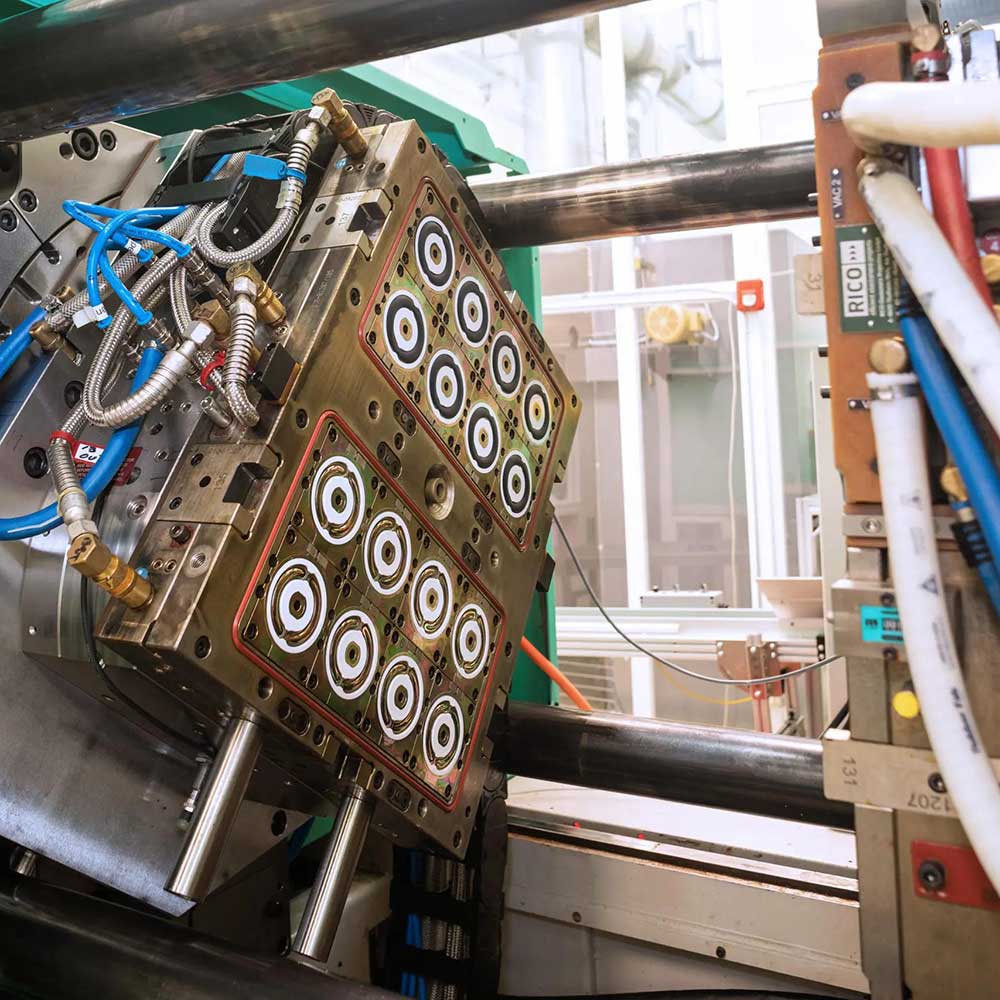

Formioo is a professional injection molding manufacturer in China, providing low-volume manufacturing services for custom plastic parts with high precision and fast turnaround. Equipped with in-house mold fabrication, rapid tooling systems, and a full fleet of injection molding machines, we are capable of producing low to mid-volume parts, typically from 50 to 5,000 units, while maintaining tight tolerances and consistent quality.

Our low-volume injection molding service is ideal for prototyping, bridge production, and early-stage product launches. We help customers shorten development cycles, reduce tooling investment, and iterate designs quickly. From DFM analysis and material selection to surface finishing and secondary machining, our team offers full technical support to ensure your parts meet both functional and cosmetic requirements, without the cost burden of mass production.

Formioo produces thousands of low-volume molded components each month, supporting clients in automotive, medical, consumer electronics, aerospace, industrial equipment, and product development sectors. Whether you’re validating a new design or fulfilling limited production runs, we provide flexible capacity, fast lead times, and stable supply tailored to your needs.

Our Low-Volume Manufacturing Capabilities

Formioo offers flexible low-volume manufacturing solutions by combining injection molding, CNC machining, 3D printing, and rapid tooling. These technologies allow us to produce high-quality parts in quantities ranging from a few dozen to several thousand, ideal for prototyping, bridge production, and pre-market testing. We work with a wide selection of thermoplastics such as ABS, PC, PP, PA, PBT, and high-performance materials like PEEK and PPS, as well as aluminum and engineering-grade resins for hybrid processes.

To meet both visual and functional standards, we provide various surface finishing options, including polishing, texturing, painting, silk screen printing, pad printing, laser marking, and vapor smoothing. Depending on the process and material, we can achieve dimensional tolerances of ±0.05 mm for injection molded parts and up to ±0.01 mm for CNC-machined features. All parts undergo quality inspection using CMMs, digital calipers, and visual checks to ensure repeatability and consistency across small batches.

A Full-Suite of Production Capabilities

Material Compatibility

Capable of printing PLA, ABS, PETG, Nylon (PA), TPU (flexible materials), and photosensitive resin, meeting various injection mold testing and product needs.

Printing Accuracy

Standard tolerance controlled within ±0.1mm, suitable for most industrial rapid prototyping and low-volume production.

Maximum Build Size

Maximum single print size of 300mm × 300mm × 400mm, ideal for small to medium-sized molds or products.

Layer Thickness Range

Variable layer thickness, typically 0.1mm - 0.3mm, balancing between printing speed and precision of details.

Delivery Time

Standard 3D printing delivery time is 2-5 days; complex structures may require longer. Expedited service is available.

Massive Network

We work with trusted injection molding suppliers.

Study Case of Our Low-Volume Manufacturing?

A Dedicated Team For Dependable Service & Quality

With experienced engineering and operations team to help you with instant quotations, production, and delivery. We help to dealing with varying requirements of material and tolerance in the most challenging industries since 2016 .

- On-Site Quality Inspections & Production Audits

- Advanced Product Quality Planning

- Production Part Approval Process

- Mechanical Assembly Services

- Coordinate Measurement Machine (CMM) Inspections

- Material Certifications

How it Works

Quote Your Production

Our platform makes it easy to quote a large bill of materials at any quantity, across a wide range of processes and materials. Not ready to quote? Talk to our team for a free initial consultation.

Review Manufacturability Assessment

Our expert team of engineers will assess your designs and provide in-depth manufacturability feedback via our technology platform and in-person consultations.

Explore Cost-Down Opportunities

Based on your goals and target pricing, our strategic sourcing team will present suggestions and opportunities on how to remove cost from your bill of materials.

Production Begins

Once the designs and sourcing strategy are finalized, we will kick off production with the ideal manufacturing partner(s) for your program, managing the schedule and quality at every step.

Post-Processing and Assembly

Our platform makes it easy to quote a large bill of materials at any quantity, across a wide range of processes and materials. Not ready to quote? Talk to our team for a free initial consultation.

Packaging and Delivery

Our platform makes it easy to quote a large bill of materials at any quantity, across a wide range of processes and materials. Not ready to quote? Talk to our team for a free initial consultation.

Fomioo Low-Volume Production FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

How long does low-volume manufacturing usually take?

Time relies on the volume, manufacturing technology, and complexity of products. Low-volume production is quicker in most cases, but the production cycle must nevertheless be taken into consideration in some situations.

What types of products can be low-volume produced?

Suitable for products which should be personalized, customized, or customized based on specific needs, for example, limited edition products, prototype design, special customized accessories, etc.

Which sectors commonly use low-volume production?

Low-volume production is widely practiced in the development of new products, custom products, medical devices, aerospace, automotive, electronic devices and many other fields.

What kind of materials does Formioo manufacture for its low-volume manufacturing service?

We typically work with all common metals like copper, brass, mild and stainless steel, magnesium, and aluminum. We also have a robust supply base with thousands of commercial plastic resins ranging from clear plastics, engineering- and medical-grade plastics, glass-filled plastics, to numerous others.

Do you offer free samples?

Yes, free swatches and stock samples are free, but the shipping needs to be paid at customer’s side.

What file format do we use?

All is acceptable, including AI, tif, jpg, psd, and pdf.

Put your parts into production today

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.