Custom Insert Injection Molding Services

Formioo offers custom insert injection molding services for rapid prototyping and low-to-high volume production with high precision and fast turnaround times.

- Upload your part to get a free instant quote

- More than ten years of professional experience in insert injection molding

- Precision insert injection molding with ±0.01 mm tolerance

- 24/7 engineering support

Reliable Insert Injection Molding Manufacturer from China

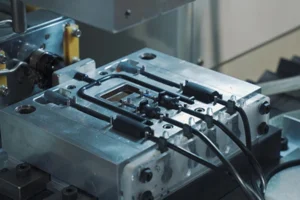

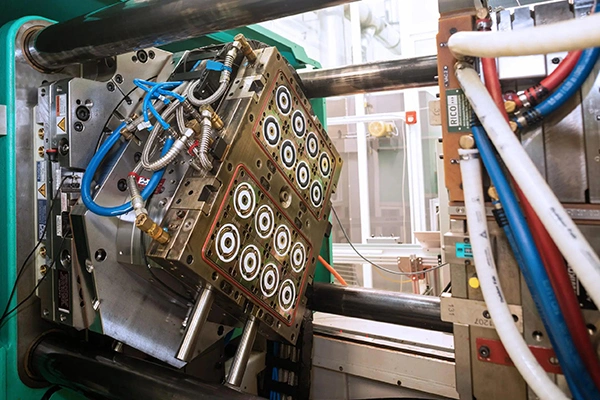

Formioo is a professional insert injection molding manufacturer in China, offering high-precision insert molding services for both rapid prototyping and full-scale production. With advanced vertical and horizontal injection molding machines, automated insert loading systems, and in-house tooling capabilities, we ensure fast turnaround and reliable mold integration of metal, ceramic, or electronic inserts.

Our insert molding process enables the seamless combination of plastic and other materials into a single durable component—eliminating the need for secondary assembly and reducing production costs. We provide DFM feedback early in the design phase, helping customers avoid common alignment and bonding issues. Whether for mechanical strength, electrical conductivity, or EMI protection, our solutions enhance product performance and assembly efficiency.

Since our founding in 2016, Formioo has delivered over 100,000 insert-molded parts annually to clients across the automotive, medical, electronics, and consumer goods industries. We support both low-volume development and high-volume production with consistent quality and short lead times, helping global customers accelerate time to market.

Our Insert Injection Molding Services

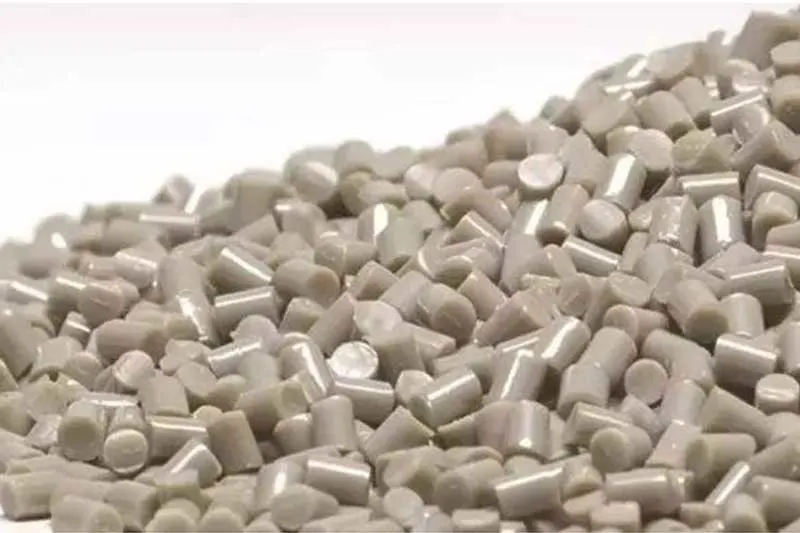

Formioo provides a complete range of insert injection molding capabilities, including vertical and horizontal molding, automated insert placement, ultrasonic metal embedding, and reel-to-reel insert molding. We work with various thermoplastics, such as ABS, PC, PA, PBT, and PPS, combined with inserts made of brass, copper, stainless steel, or ceramics to produce integrated parts with enhanced structural and functional performance.

Our insert molded parts can be customized with surface finishes, including texturing, laser marking, electroplating, pad printing, and painting to meet both aesthetic and functional requirements. With advanced molding and quality control systems in place, we achieve tight tolerances of ±0.01 mm, ensuring precise insert positioning, strong material bonding, and long-term dimensional stability across high-volume or prototype projects.

Overmolding places a preformed insert beneath a secondary material molded over it for structure and surface beauty.

In-mold assembly inserts parts into the mold before injection, allowing for concurrent integration with reduced follow-on assembly operations.

Two-shot molding employs successive injections of different materials, manufacturing complex, multi-material parts in a single cost-effective molding operation.

Multi-shot molding injects multiple materials into one mold cavity simultaneously to create differentiated color zones and enhanced functional performance.

Insert Injection Molding Capabilities

Material Compatibility

We are capable of molding ABS, PP, PC, POM, Nylon, PEEK, and other engineering plastics, meeting various industrial and custom production needs.

Printing Accuracy

Our standard tolerance is controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Maximum Build Size

Our maximum molding size is up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Surface Finishing Options

We support polishing, painting, sandblasting, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Our standard injection molding lead time is 5-10 working days with rush service available on urgent work.

Massive Network

We work with trusted injection molding suppliers.

Explore Insert Injection Molding Parts We Manufactured

See our high-quality insert injection molding parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Insert Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Insert Molding Parts | +/- 0.2 mm to +/- 0.5 mm |

| High-Precision Insert Molding Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Insert Molding Parts | +/- 0.3 mm to +/- 0.6 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Insert Injection Molding Materials

PP

Polypropylene (PP) is ideally utilized for insert injection molding due to its economic cost, good chemical resistance, and low density. Its weldability is high, which ensures the metal insert bond is strong, and thus it finds itself well applied in complex multi-component parts. PP is used in automotive interior, home appliances, and electronic devices. For example, it is normally used for overmolding metal brackets in dashboards, anchoring fasteners in electronic enclosures, and producing tough connectors in fluid systems. Its ability to be easily processed and its versatility lead to it being a high-volume production material.

- Mill Lead Time: 3-5 days

- Color: White, natural with customizable options

PE

Polyethylene (PE) is valued in insert injection molding due to its water resistance, processability, and flexibility. It becomes well bonded with metal inserts, so it is applicable to various uses like medical devices, protective enclosures, and components of packaging. For example, PE is applied to overmold thread-in-place metal inserts in fluid connectors, add strength to outdoor gear structural parts, and provide bonding security in piping systems. Since it is extremely low-cost and provides uniform performance in a range of conditions, it facilitates strong, durable components in both industrial applications and consumer goods.

- Mill Lead Time: 4 days

- Color: Translucent white with multiple shade options

PS

Polystyrene (PS) possesses good dimensional stability and surface finish quality and hence plays a critical role in precise insert injection molding. It can be easily bonded to various inserts, forming lightweight but rigid parts. PS is greatly applied in consumer electronics cases, disposable medical products, and aesthetic components. For example, it’s applied for metal fastener overmolding in LED frames, tactile button panel forming, and insert integration in intricate designs. Its cost-efficiency and processability make PS a highly appropriate choice for precision, high-volume applications.

- Mill Lead Time: 2-4 days

- Color: Clear with options for tinted finishes

PVC

Polyvinyl Chloride (PVC) has excellent weather and chemical resistance, thus a highly powerful material in insert injection molding. Its impact resistance and strength provide good bonding with metal inserts. PVC is widely used in construction fittings, industrial enclosures, and cable insulation. For instance, it is widely used to overmold metal connectors in pipe systems, embed electrical modules in protective housings, and form high-strength seals on metal pieces. Its performance in processing and compatibility with a vast array of inserts make it a suitable option for cost-effective, creative designs.

- Mill Lead Time: 5 days

- Color: Gray with customizable color options

PC

Polycarbonate (PC) is very resistant, transparent, and heat-resistant, making it a superb option for insert injection molding. It is quickly integrated with metal or fiber-reinforced inserts to enhance the strength and durability of components. PC also appears in electronic enclosures, medical devices, and automotive lighting. PC is, for example, widely utilized to overmold metal hinges on devices, insert fasteners into clear housings, and be combined with metal inserts in secure electrical modules. Its stunning impact resistance and clarity lead to high-quality, reliable designs.

- Mill Lead Time: 3 days

- Color: Transparent with available tinted variations

PA

Polyamide (Nylon) is well-suited for insert injection molding because it has very good strength, wear resistance, and heat stability. It adheres well with metal inserts to create strong and lasting parts. Nylon finds large-scale usage in gear housings, heavy-duty fasteners, and mechanical parts of automotive and aerospace applications. For example, it is employed in overmolding threaded inserts in electrical connectors, making metal frames stiff, and creating long-lasting structural parts. Its high stress and changing condition performance guarantees long-term performance in harsh conditions.

- Mill Lead Time: 4 days

- Color: Natural with a range of dye options

POM

Acetal (POM) is the first choice for applications in insert injection molding because of high stiffness, low friction, and excellent dimensional stability. They make it ideal to couple strongly with metal or another insert to produce strong, accurate parts. It is extensively utilized in mechanical gears, fasteners, and precision components in automotive and electronics industries. For instance, Acetal is employed to overmold metal bushings, hold embedded fasteners, and support assembly parts for enhanced wear life. Its long-term performance and steady processing behavior make it a worthwhile option for high-performance engineering uses.

- Mill Lead Time: 4 days

- Color: White with versatile finish options

PEEK

PEEK is a high-performance polymer featuring good chemical resistance, hot temperature stability, and strong mechanical strength. These features make it a prime choice for insert injection molding where strength is a critical consideration. PEEK always sticks to metal inserts and exhibits better performance in aggressive applications. It is used extensively in aerospace hardware, medical implants, and high-performance car parts. For example, PEEK is used for metal connector overmolding in high-temperature applications, retaining instrument components, and reinforcing key assemblies. Because it maintains strength in aggressive environments, it is an upscale material used for advanced engineering applications.

- Mill Lead Time: 7 days

- Color: Natural with customizable finishes

PPS

PPS offers excellent chemical resistance, dimensional stability, and thermal performance that are critical for demanding insert injection mold applications. Its ability to adhere well to metal inserts makes it eligible to be applied in parts operating in harsh environments. PPS is used mainly in electrical connectors, motor vehicle under-hood components, and industrial equipment parts. For instance, PPS is employed in overmolding metal terminals, holding fasteners at high temperature, and enhancing electronics’ housings for durability. Its excellent performance and precision processing ensure uniform quality in precision-driven projects.

- Mill Lead Time: 6 days

- Color: Dark gray with multiple shade options

LCP

Liquid Crystal Polymer (LCP) is a high-strength product with maximum desirability because of its improved mechanical strength, dimensional stability, and heat resistance. These features make it especially suitable for insert injection molding where precision matters. LCP has excellent adhesion with metal and other insertions, enabling the production of fine, high-precision parts. It is commonly used in high-frequency electronic components, medical devices, and automotive sensors. LCP is, for example, used to overmold connectors on circuit boards, embed fasteners in small housings, and produce robust parts in aggressive applications. Its superior flow and stability enable high-quality, compact designs.

- Mill Lead Time: 5 days

- Color: Silver with a smooth

PI

PI (Polyimide) is a high-temperature thermoplastic particularly well-suited for Insert Injection Molding due to its excellent thermal stability, resistance to chemicals, and strength. PI also exhibits good adhesion to metal inserts and can endure harsh environments. PI is commonly used in aerospace-grade connectors, automotive sensor housings, and high-temperature electronic components.

- Mill Lead Time: As fast as 7 days

- Color: Brown, Custom Colors Available

Finishing Options for Insert Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum, Zinc | Clear, gold | Media Blasting, Tumbling, Type II Anodizing, Type III Anodizing with PTFE |

|

Anodizing | Aluminum | Clear, Black, Gold | Type II Anodizing, Type III Anodizing |

|

Plating (Chrome, Nickel) | Steel, Brass, Aluminum | Chrome, Nickel, Gold | Electroplating, Electroless Plating |

|

Powder Coating | Steel, Aluminum | Various Colors | Electrostatic Application |

|

Laser Engraving | Aluminum, Stainless Steel | — | Laser Marking, Laser Etching |

|

Spray Coating | Plastic, Metal | Glossy, Matte | Spray Guns, Electrostatic Spray |

|

Polishing | Steel, Aluminum, Brass | — | Buffing, Abrasive Polishing |

|

Vibratory Finishing | Plastic, Metal | — | Media Tumbling, Vibro Finishing |

|

Coating (PTFE, Teflon) | Steel, Aluminum | White, Black | Coating, Dip Coating, Spray Coating |

|

Heat Treatment | Steel, Aluminum, Stainless Steel | — | Furnace Treatment, Induction Hardening |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Insert Injection Molding Supplier Selection Ultimate Guide

Which insert injection Molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Insert Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Can you handle high-volume production for insert molding?

Yes, we do have the facility for high volume runs and lower volume batch runs, ensuring quality consistency every time.

How do you prevent insert damage during molding?

Our precise molding process and tooling ensure inserts are kept intact and precisely aligned.

What is your history with medical-grade insert molding?

We’re ISO-certified and knowledgeable about medical-grade use to satisfy strict industry demands.

Do you provide design-for-manufacturability (DFM) analysis?

Yes, our engineers would also review your design to see that it’s optimized for cost, performance, and manufacturability.

What is your insert molding project turnaround time?

Typically 4-6 weeks, but we have expedited processes for urgent projects. Share with me your timeline.

Do you offer post-molding services like assembly or testing?

Yes, we have facilities such as assembly, testing, and packaging to ease your process.

Insert Injection Molding Resource

Are You Looking for Insert injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.