Custom Injection Molding Services

Formioo offers injection molding services for both prototyping and full-scale production, with custom plastic molded prototypes and production parts available in as fast as 5 business days.

- 10+ injection molding production experience with in-house production facilities

- High-Precision Injection Molding with close tolerance and high quality consistency

- Reusable part quality

- 100+ Third-party Certified materials including ABS, PC, PP, POM, Nylon, and more

- Delivery completed in as little as 5 days

Reliable Injection Molding Supplier from China

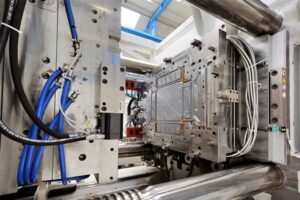

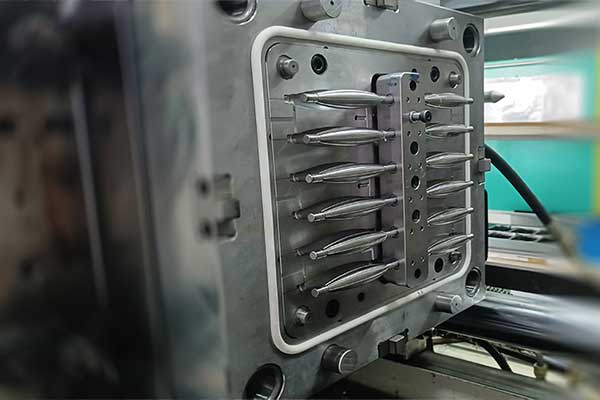

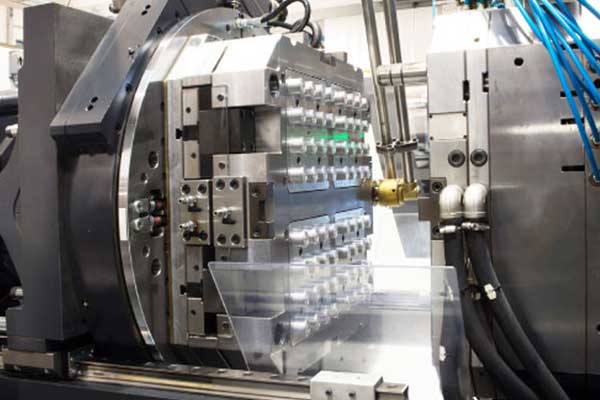

Formioo is a professional injection molding manufacturer based in China, offering high-quality custom plastic parts for both rapid prototyping and mass production. Our factory is equipped with advanced electric and hydraulic injection molding machines, in-house mold fabrication workshops, and strict quality inspection systems, allowing us to handle projects with complex geometries, tight tolerances, and fast turnaround requirements.

As an experienced molding service provider, we help customers overcome common production challenges such as thin-wall molding, tight draft angles, undercuts, dimensional stability, and flawless surface finishes. We also provide DFM feedback and mold flow analysis to ensure cost-effective and manufacturable designs from the start. Whether you’re developing a precision component or a high-volume product, Formioo ensures consistent quality and smooth production at every stage.

With over 10 years of manufacturing experience, we produce hundreds of thousands of molded parts annually for global clients across the automotive, medical, electronics, consumer, and industrial sectors.

Explore Our Injection Molding Capabilities

Formioo offers advanced injection molding services, including Plastic Injection Molding, Liquid Silicone Rubber (LSR) Molding, and Metal Injection Molding (MIM), to meet a wide variety of production needs. We support a broad range of materials such as ABS, PC, POM, PA, TPU, medical-grade LSR, and stainless steel or iron-based powders for MIM, making us capable of producing complex parts across medical, automotive, electronics, and industrial sectors.

We also provide secondary services such as overmolding, insert molding, and part marking. Surface finish options include high-gloss polishing, SPI-A to D textures, bead blasting, and laser etching. Depending on material and process, we achieve tight tolerances of ±0.05 mm for plastic parts and ±0.03 mm for metal parts, ensuring high dimensional accuracy and consistency throughout production.

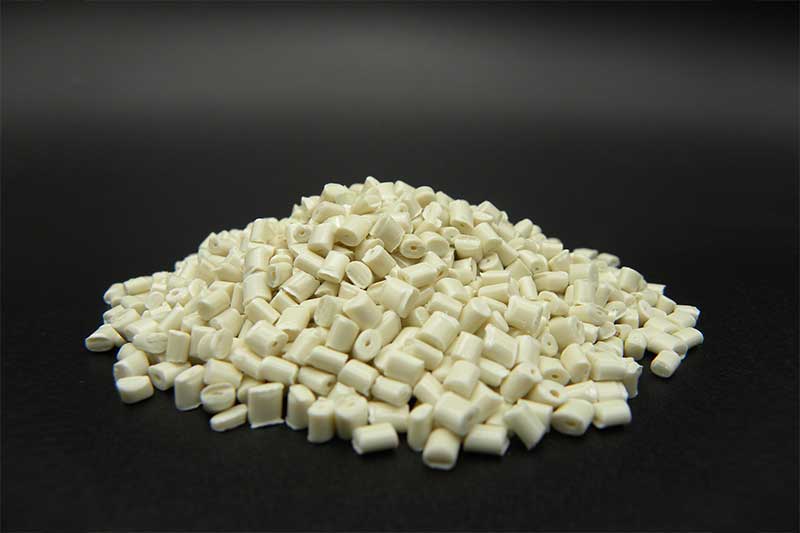

Thermoplastic is the most utilized material in custom plastic injection molding and is employed for an extensive range of applications including consumer items, car components, and more.

Liquid silicone rubber is an inert and biocompatible material, making it ideal for molding medical items such as fluid management systems and respiratory devices.

Metal Injection Molding (MIM) is a cost-effective method for small, intricate metal component manufacturing. It is economical for bulk production and conserves material waste compared to CNC machining.

Injection Molding Capabilities

Material Compatibility

Having the capability to machine ABS, PP, PC, POM, PA (Nylon), PBT, PE, PS, TPU, PEEK, and other engineering plastics, with different industrial and bespoke production needs.

Molding Precision

Standard tolerances held at ±0.05mm as default, offering accurate precision for automotive, medical, and consumer electronics applications.

Maximum Part Size

Comprises up to 1000mm × 800mm × 500mm injection molding, suitable for small and medium parts.

Molding Techniques

Offers single-shot, multi-shot, overmolding, insert molding, micro molding, gas-assisted molding, and more for complex part designs.

Production Lead Time

Standard injection molding lead time of 7 days; rush options are available for urgency-based projects.

Explore Injection Molding Parts We Manufactured

See our high-quality injection molding parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Injection Molding Tolerance

| Part Type | Tolerance Range |

|---|---|

| Standard Injection Molding | +/- 0.1 mm to +/- 0.2 mm |

| Precision Injection Molding | +/- 0.05 mm or tighter |

| Large Parts | +/- 0.2 mm to +/- 0.5 mm |

| Thin-Walled Injection Parts | +/- 0.2 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Injection Molding Materials

ABS

ABS (Acrylonitrile Butadiene Styrene) is a commodity injection-molding thermoplastic for broad use due to its impact strength, toughness, and processability. It possesses good mechanical features, thermal stability, and chemical inertness and is thus used in car parts, household appliances, and consumer products. ABS also is easily paintable, platable, or texturable for added beauty and functionality. Its cost efficiency and all-around technological properties make it best popular for durable plastic components.

- Production Lead Time: Up to 7 days

- White, Black, Gray, Natural, Custom Colors Available

PP

PP (Polypropylene) is a lightweight, flexible thermoplastic widely used in injection molding for its excellent chemical resistance, fatigue strength, and low moisture absorption. It offers good impact resistance, thermal stability, and electrical insulation properties, making it ideal for automotive components, medical devices, packaging, and household goods. PP is also highly recyclable and can be modified with additives to enhance its mechanical properties. Its affordability and versatility make it a preferred choice for a wide range of applications.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PE

PE (Polyethylene) is a durable and flexible thermoplastic widely used in injection molding for its excellent impact resistance, chemical stability, and moisture resistance. It is lightweight, has good electrical insulation properties, and is available in different densities (LDPE, HDPE) to suit various applications. PE is commonly used in packaging, automotive components, piping, and consumer goods. Its low cost, ease of processing, and recyclability make it a preferred material for both industrial and commercial products.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PS

PS (Polystyrene) is a rigid and lightweight thermoplastic widely used in injection molding due to its excellent clarity, ease of processing, and affordability. It offers good dimensional stability, electrical insulation, and chemical resistance, making it ideal for packaging, disposable containers, consumer electronics, and household products. PS is available in both general-purpose (GPPS) and high-impact (HIPS) variants, catering to different strength and flexibility requirements. Its cost-effectiveness and versatility make it a popular choice for various applications.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PVC

PVC (Polyvinyl Chloride) is a durable and versatile thermoplastic widely used in injection molding due to its excellent chemical resistance, flame retardancy, and mechanical strength. It offers good impact resistance, weatherability, and electrical insulation properties, making it ideal for pipes, fittings, medical devices, automotive parts, and consumer goods. PVC can be formulated as rigid (RPVC) or flexible (FPVC) to suit different application needs. Its cost-effectiveness and adaptability make it a preferred material for industrial and commercial products.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PC

PC (Polycarbonate) is a heat-sensitive resin that has high strength with good impact resistance, light transmission, and thermal stability. It is dimensionally stable with good fire retardancy and UV stability, being applicable for automotive components, electronic housings, medical devices, and transparent products like lenses and shields. PC can easily be molded and post-formed to attain better form and function. It is appropriate for difficult engineering applications because of its strength and flexibility.

- Production Lead Time: As fast as 7 days

- Color: Transparent, White, Black, Gray, Custom Colors Available

POM

POM (Polyoxymethylene) or Acetal, or Delrin, is an engineering thermoplastic that exhibits good mechanical strength, wear resistance, and low friction. It is a chemical-resistant, long-life, and high-dimensional stability material applied to precision gears, automotive components, bearings, and industrial applications. POM is widely used in high stiffness and low moisture absorption.

- Production Lead Time: 7 days maximum

- Color: White, Black, Gray, Natural, Optional Custom Colors

PA

PA (Polyamide), commonly known as Nylon, is a strong and durable engineering thermoplastic with excellent mechanical strength, wear resistance, and chemical stability. It offers high impact resistance, good thermal performance, and low friction, making it ideal for automotive components, industrial gears, bearings, and consumer goods. PA is available in various grades (PA6, PA66, PA12) and can be reinforced with glass fiber for enhanced strength. Its versatility and reliability make it a preferred material for demanding applications.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PET

PET (Polyethylene Terephthalate) is a strong and lightweight thermoplastic known for its excellent mechanical properties, chemical resistance, and dimensional stability. It offers high stiffness, low moisture absorption, and good heat resistance, making it ideal for food packaging, automotive components, electrical insulators, and industrial applications. PET can be reinforced with glass fiber for enhanced strength and wear resistance. Its durability, recyclability, and versatility make it a widely used material in injection molding.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PBT

PBT (Polybutylene Terephthalate) is a high-performance engineering thermoplastic known for its excellent mechanical strength, heat resistance, and electrical insulation properties. It offers high dimensional stability, low moisture absorption, and good chemical resistance, making it ideal for automotive components, electrical connectors, and industrial applications. PBT can be reinforced with glass fiber for enhanced strength and durability. Its reliability and processing ease make it a preferred material for precision-molded parts.

- Production Lead Time: As fast as 7 days

- Color: White, Black, Gray, Natural, Custom Colors Available

PEEK

PEEK, or Polyether Ether Ketone, is a high-temperature thermoplastic offering enhanced mechanical toughness, thermal stability, and chemical inertness. It is more resistant to wear, features less friction, and enhanced dimensional stability and can be used in aerospace, medical, automotive, and industrial applications. It is biocompatible, highly resistant to hostile environments, and metal-substitutable-like in hostile environments. Its enhanced properties make it the superior option for precision-engineered components that demand reliability and endurance.

- Production Lead Time: As fast as 7 days

- Color: Natural, Black, Gray, Custom Colors Available

PEI

PEI (Polyetherimide) is a high-performance thermoplastic with enhanced heat resistance, mechanical characteristic, and electrical insulation. PEI boasts enhanced dimensional stability, fire resistance, and chemical resistance and is thus best suited for aerospace, automotive, medical, and electronic applications. PEI is commonly used as a light-weight metal replacement in high-temperature applications. PEI is best suited for demanding engineering applications due to its high toughness and strength.

- Production Lead Time: As short as 7 days

- Color: Natural, Amber, Black, Custom Colors Available

LCP

LCP or Liquid Crystal Polymer is a high-performance thermoplastic with superior mechanical properties, high temperature and high dimensional stability. It has good chemical resistance, lower water absorption, and superior flow properties and thus becomes highly suitable for automotive, medical, aerospace components, and micro-precision electronics. LCP is widely used in connectors, circuit boards, and in other heat applications where reliability and stability are a necessary requirement.

- Production Lead Time: Up to 7 days

- Color: Natural, Black, Custom Colors Available

PPS

PPS (Polyphenylene Sulfide) is a heat-resistant high-performance thermoplastic polymer with superior heat resistance, chemical stability, and mechanical strength. PPS is highly dimensionally stable, fire-resistant, and water-resistant, and hence suitable for usage in the automobile, aerospace, electrical, and industrial sectors. PPS is generally used in high-heat-resistant components and challenging applications such as pump housings, electric connectors, and mechanical components of high precision. Its reliability and long term performance make it the industry best solution for challenging engineering applications.

- Production Lead Time: As fast as 7 days

- Color: Natural, Black, Gray, Custom Colors Available

PVDF

PVDF is a thermoplastic with high performance which has improved chemical resistance, heat stability at high temperature, and improved mechanical performance. PVDF has greater UV resistance, greater flame resistance, and lesser moisture absorption than other materials and hence is being utilized for chemical process service, electrical insulation, aerospace, and health-oriented exposures. PVDF finds extensive application in piping systems, fluid-handling equipment, and high-performance electronic components. The high strength of PVDF and resistance to harsh environments make it eligible to be the first choice for demanding applications.

- Production Lead Time: A maximum of 7 days

- Color: Natural, White, Black, Custom Colors Available

Finishing Options for Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing with PTFE* |

|

Type II Anodizing | Aluminum | Clear, Gold | Media Blasting, Tumbling, Chem Film |

|

Type III Anodizing | Aluminum | Black, Gray | Media Blasting, Tumbling, Chem Film |

|

Powder Coating | Metals, Plastics | Wide range | Electrostatic Spray, Fluidized Bed |

|

Electroplating | Metals, Plastics | Silver, Gold, Chrome | Electrochemical process |

|

Vapor Polishing | Plastics | Transparent, Clear | Polishing Vapor for Smooth Finish |

|

Bead Blasting | Metals, Plastics | Matte finish | Media Blasting |

|

Tumbling | Metals, Plastics | Satin finish | Rotary, Vibratory Tumbling |

|

Laser Etching | Metals, Plastics | Black or Grey | Laser Beam |

|

UV Coating | Plastics, Glass | Clear, Glossy | UV Curing Process |

|

Silk Screening | Plastics, Metals | Various | Screen Printing Process |

- *Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. For materials not listed here, please contact us directly.

Your Injection Molding Supplier Selection Ultimate Guide

Which injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Injection Molding Service FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What is the minimum order quantity for injection molding?

Formioo is happy to offer you injection molding services with NO minimum order quantity.

Can you provide a no-obligations estimate for my injection molding project?

Absolutely. As long as you can provide project requirements and part specifications, Formioo is happy to offer a no-obligation quotation.

Once I have a mold, can I reorder from it?

Of course! Formioo will maintain your mold for 2 years after your most recent order, allowing you to reorder parts throughout the mold’s life.

Does Formioo charge an inventory fee on my molds?

No, Formioo doesn’t charge inventory fees for molds as long as they’re used within 2 years. After 2 years of inactivity, we’ll ship or destroy the mold as per your instructions.

Does Formioo provide DFM on my part design before I place an order?

Yes, we do! You can access your DFM and 3D visualizations on the Formioo platform, comment, annotate, and discuss with a technical project lead before placing your order.

Does Formioo charge for DFM feedback?

At Formioo, we believe in delivering the best possible parts on the first try. That’s why we provide DFM feedback at no cost, ensuring you have all the information you need before placing your injection molding order.

What DFM analyses does Formioo provide?

Injection molding may be involved, and we help our customers keep it simple. We offer draft, thickness, and sink analysis with every quotation. Advanced DFM services, such as parting line visualization, side action analysis, and mold-flow analysis, are available upon request.

How long does it take to make molded parts?

Once the material and mold are prepared, the injection molding process can produce several hundred molded parts in a day, depending on the needs of production and part complexity. Initial configuration to set the molds and get the material may require a couple of days, but once the production is in progress, it can be quite efficient with regular throughput. For mass production runs, schedules will vary based on part size, features, and finishing or post-process steps required. Formioo works with you to provide precise schedules and meet deadlines.

Injection Molding Resource

Are You Looking for Injection Molding Supplier in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.