In-Mold Decoration Small Batch Production

Formioo provides flexible in-mold decoration services with low minimum order quantities, fast turnaround times, and full customization.

- High-quality In-Mold Decoration with precise color and pattern integration

- More than 10 years of experience in the injection molding industry

- Wide range of decoration options & materials, tailored to your design needs

- 24/7 engineering support

In-Mold Decoration (IMD) Services Provider from China

Formioo is a professional IMD manufacturer based in China, offering integrated in-mold decoration (IMD) solutions that combine form, function, and aesthetics. With state-of-the-art molding equipment, precise printing capabilities, and automated production lines, we deliver decorative plastic parts with consistent quality and high visual appeal, whether for prototyping or large-scale production.

Our IMD service enables brands to enhance product surface durability, abrasion resistance, and aesthetic detail without secondary operations. We provide rapid DFM feedback, fast mold fabrication, and flexible order volumes, helping clients shorten development cycles, reduce unit cost, and avoid post-processing errors. Whether you’re creating intricate graphic overlays or functional user interfaces, we make complex designs manufacturable at scale.

Established in 2016, Formioo manufactures tens of thousands of IMD parts annually and supports customers across automotive interiors, medical devices, consumer electronics, and home appliance industries. Our scalable manufacturing system and tight quality control ensure consistent delivery and global reliability.

Our In-Mold Decoration Services

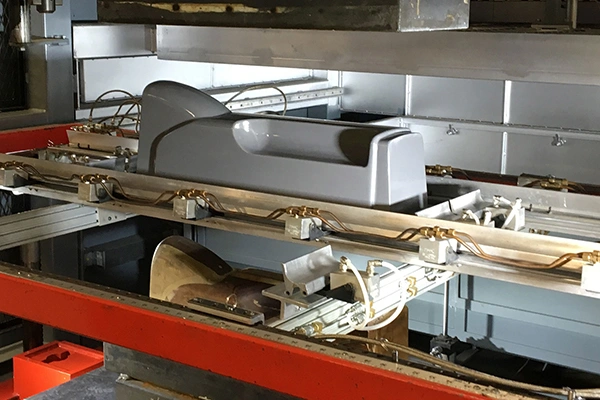

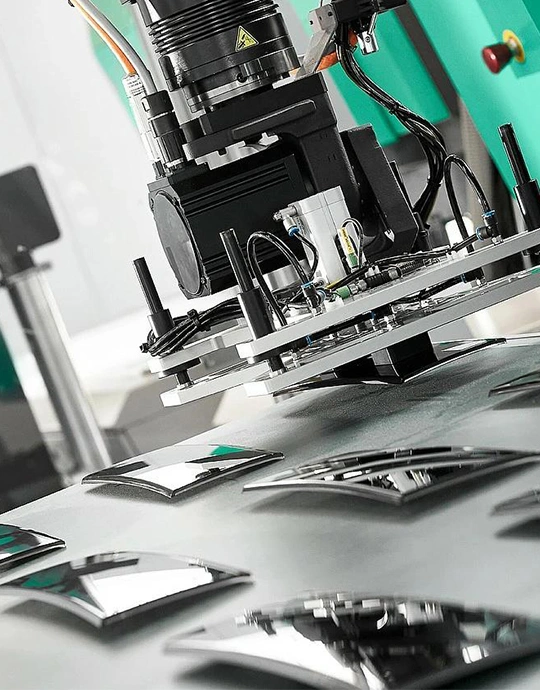

Formioo offers complete in-mold decoration (IMD) solutions, integrating multiple manufacturing steps, printing, thermoforming, precision die-cutting, and injection molding into a streamlined production process. This allows us to produce plastic parts with high-resolution graphics, wear-resistant surfaces, and complex contours in a single cycle. Our IMD process supports both 2D and 3D decorated surfaces for functional and aesthetic applications.

We support a wide range of decorative films and substrates, including PC, PET, and PMMA, enabling exceptional print clarity and surface durability. With advanced equipment and tight process control, our in-mold decorated parts can achieve tolerances as precise as ±0.05 mm. In addition to molding, we offer optional surface enhancements such as UV coating, hard coating, or anti-fingerprint finishes, ensuring long-lasting performance under demanding usage conditions.

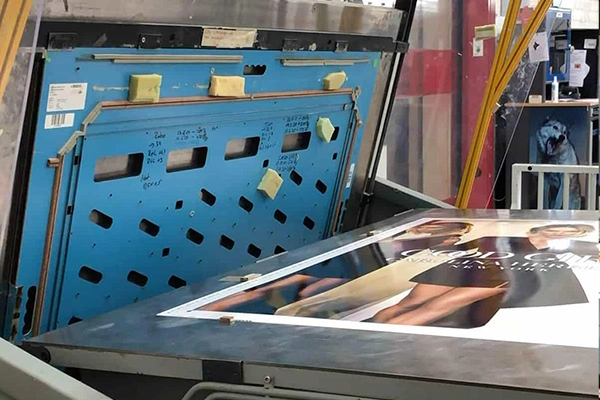

High-precision printing of designs on film.

Shaping printed film into 3D structures.

Precision cutting of formed film.

Embedding film into molded parts.

In-Mold Decoration Capabilities

Material Compatibility

Our In-Mold Decoration process handles various engineering plastics such as ABS, PC, and PP, as well as specialty decorative film, to cater to different specifications.

Printing Accuracy

Achieving excellent color and pattern integration with minimal deviations.

Maximum Build Size

Processes pieces up to 1000mm × 600mm × 500mm, ideal for small and medium-sized pieces.

Decoration Options

Offers finishes including matte, gloss, metallic, and texture effect.

Delivery Time

Standard lead time is 7-14 days, with expedited options available.

Massive Network

We work with trusted injection molding suppliers.

Explore Latest In-Mold Decoration Products We Manufactured

Explore our beautifully in-mold decorated injection molded products and witness the perfect blend of aesthetics and functionality. From rapid prototyping to full-scale production.

In-Mold Decoration Tolerance

| Name | Tolerance Range |

|---|---|

| Standard In-Mold Decoration Parts | +/- 0.3 mm to +/- 0.6 mm |

| Precision In-Mold Decoration Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex In-Mold Decoration Parts | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

In-Mold Decoration Materials

PP

PP is widely used in IMD for its excellent chemical resistance, flexibility, and low cost. It is best suited to make household packaging, automotive trim, and consumer electronics enclosures. For instance, PP is frequently employed in dishwasher-safe food containers because of its toughness and heat resistance.

- Mill Lead Time: Up to 3 days

- Color: Translucent, white, custom colors

PE

PE is suitable for IMD applications that possess high impact strength and water resistance. PE may be used in packaging, toys, and industrial parts. For instance, PE is used in squeeze containers and caps due to its flexibility and moldability.

- Mill Lead Time: Up to 3 days

- Color: Natural, white, custom colors

PVC

PVC is used in IMD due to the fact that it is wear-resistant, flame-resistant, and cost-effective. It is mostly used in signs, medical devices, and car interiors. For example, PVC is used in dashboard trim and in medical tubing for chemical and rigidity

- Mill Lead Time: Up to 4 days

- Color: Transparent, white, custom colors

PC

PC is preferred for IMD applications requiring high transparency and impact strength. It is used in eyewear lenses, medical devices, and automotive lighting. For instance, PC is used in headlight covers for its clarity and resistance to UV radiation.

- Mill Lead Time: Up to 5 days

- Color: Transparent, custom colors

PMMA

PMMA is chosen for IMD due to its optical clarity and weather resistance. It is widely used in displays, light guides, and automotive windows. For example, PMMA is used in smartphone screen covers for its scratch resistance and transparency.

- Mill Lead Time: Up to 5 days

- Color: Transparent, custom colors

PEEK

PEEK is suitable for IMD in high-temperature and chemical-resistant applications.It is used in aerospace, medical implants, and automobile components. For instance, engine parts use PEEK due to its toughness and heat resistance.

- Mill Lead Time: Up to 7 days

- Color: Natural, black, custom colors

PTFE

PTFE is ideal for IMD applications requiring low friction and chemical resistance. It is used in seals, medical devices, and bearings. For example, PTFE is used on non-stick pans due to high non-stick capabilities.

- Mill Lead Time: Up to 7 days

- Color: White, custom colors

PPS

PPS is chosen for IMD due to its high thermal stability and flame resistance. It is used in electrical components, motor vehicle parts, and manufacturing equipment. One example is the use of PPS in sensors and connectors due to dimensional stability and chemical resistance to harsh environments.

- Mill Lead Time: Up to 7 days

- Color: Natural, black, custom colors

Finishing Options for In-Mold Decoration

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

In-Mold Decoration (IMD) | Plastic | Custom Colors | Injection Molding, Heat Transfer |

|

In-Mold Labeling (IML) | Plastic | Custom Colors | Label Insertion, Injection Molding |

|

Surface Printing | Plastic, Metal | Custom Colors | Silk Screening, Pad Printing, UV Printing |

|

Texturing | Plastic, Metal | — | Laser Etching, Mold Surface Texturing |

|

Laser Etching | Plastic, Metal | — | Laser Machines |

|

Polishing | Plastic, Metal | — | Buffing, Tumbling |

|

UV Coating | Plastic | Glossy, Matte | UV Curing Process |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

|

Anodizing | Aluminum, Metal | Clear, Black, Gold | Media Blasting, Tumbling, Anodizing |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your In-Mold Decoration Supplier Selection Ultimate Guide

Which in-mold decoration supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo In-Mold Decoration FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

How long is the lead time of IMD parts?

Generally 2-4 weeks for prototypes and 4-6 weeks for production, depending on design complexity and order size.

Is IMD appropriate for high-temperature applications?

Yes, we use high-temperature-resistant materials like PC and PMMA that can support maximum 120°C (248°F).

What is the minimum order (MOQ) for IMD components?

The MOQ is 1,000 pieces for stock designs, although we accept smaller orders for special orders or prototypes.

Are IMD components recyclable?

We can recycle most IMD materials like ABS, PP, and PC and hence an environmentally friendly option.

How durable is the decoration on IMD parts?

Very durable! The finish is covered with a protective topcoat that makes it wear, fade, and scratch resistant.

Do you provide design support for IMD projects?

Yes, our team offers free design consultation to ensure your parts are optimized for IMD manufacturing.

In-Mold Decoration Resource

Are You Looking for In-Mold Decoration Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.