High Precision Injection Molding Small Batch Production

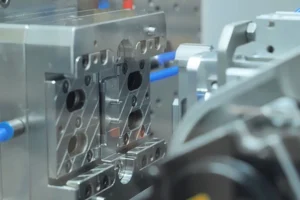

Formioo provides high-precision injection molding services for complex and tight-tolerance plastic parts, ensuring consistent quality, low-volume flexibility, and fast turnaround for demanding applications.

- Diversified precision mold design and development

- Low-burr, no-rework, no-waste parts

- More than 10 years of professional experience in high-precision injection molding

- Over 50 certified materials and 15+ finishing options available

High Precision Injection Molding Services Provider from China

Formioo is a trusted manufacturer in China specializing in high-precision injection molding for both prototype and production-grade plastic parts. With advanced molding equipment and strict process control, we deliver components that meet the most demanding dimensional and cosmetic requirements.

Our expert engineering team provides DFM support to help customers optimize their designs before tooling, minimizing the risk of costly revisions and production delays. Whether it’s tight-tolerance housings, optical components, or intricate functional parts, our molding solutions ensure consistent quality, repeatability, and performance.

Since our establishment in 2016, Formioo has supported a wide range of industries, including medical, automotive, electronics, and industrial equipment, by delivering thousands of precision-molded parts annually. We help clients accelerate product development with reliable quality and fast lead times.

Our High Precision Injection Molding Services

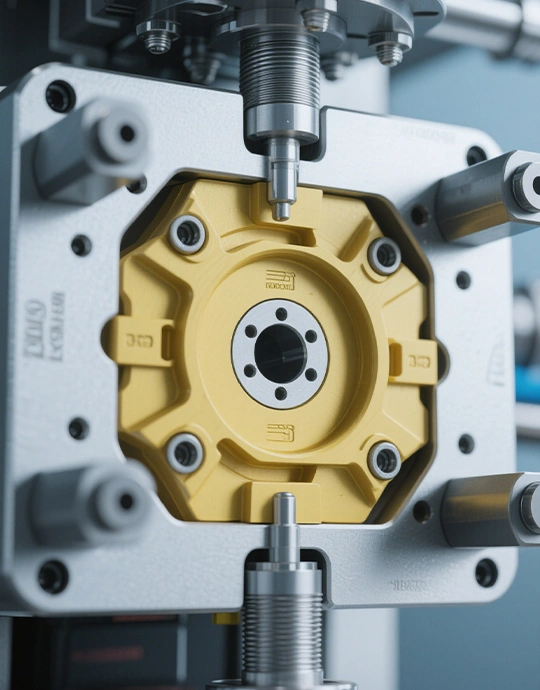

At Formioo, our high precision injection molding services include Micro Injection Molding, Insert Molding, Overmolding, and Two-Shot Injection Molding. These processes are ideal for creating miniature components, multi-material assemblies, and products requiring enhanced strength, aesthetics, or functionality. We work with a wide range of engineering-grade plastics and high-performance thermoplastics, including PEEK, PPS, PC, ABS, PA, and medical-grade materials, to meet the specific requirements of various industries.

To complement our molding capabilities, we offer multiple surface treatment options such as texturing, laser etching, pad printing, ultrasonic welding, and secondary machining. Our precision molding operations can achieve tolerances down to ±0.01 mm, supported by rigorous in-process quality control and dimensional inspections using advanced CMM and vision systems. This ensures every part meets critical performance and cosmetic standards for medical, automotive, aerospace, and electronics applications.

Produces extremely small, high-precision parts for medical and electronics.

Embeds metal or plastic inserts into molded parts for enhanced functionality.

Bonds together two or more materials within one component for improved durability and aesthetics.

Creates multi-material or multi-colored components in a single molding operation.

High Precision Injection Molding Capabilities

Material Compatibility

We support a wide range of materials like PP, ABS, POM, and Nylon that help meet the diverse requirements of companies like medical devices, packaging, automobiles, and electronics.

Printing Accuracy

Our accuracy is guaranteed with a ±0.01 mm tolerance, providing utmost quality for components utilized in delicate applications such as medical equipment and performance products.

Maximum Build Size

Our injection molding capability is capable of handling a wide range of part sizes up to 500mm × 500mm, ideal for small and medium-sized parts.

Surface Finishing Options

Finishing options such as polishing, sandblasting, and anodizing are available to provide your parts with a better finish and durability.

Delivery Time

We are able to deliver quick turnaround times for manufacturing runs or prototypes, with capability to meet deadline pressures.

Massive Network

We work with trusted injection molding suppliers.

Explore our High Precision Injection Molding Parts

Discover our precision-manufactured injection molded components. From prototyping to mass production, see the quality and consistency of our work across industries. Visit our product showcase to learn more about our high-precision capabilities.

High Precision Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard High-Precision Parts | +/- 0.05 mm to +/- 0.1 mm |

| Very High-Precision Parts | +/- 0.02 mm to +/- 0.05 mm |

| Complex High-Precision Parts | +/- 0.1 mm to +/- 0.3 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

High Precision Injection Molding Materials

PP

Polypropylene is ideally suited to be used in High Precision Injection Molding because it enjoys the benefit of chemical resistance, light weight, and fatigue life.. Its durability enables high-quality, detailed, lightweight components with assured quality to be made. PP can be utilized in the production of container caps, automotive trim components, and packaging parts. For instance, precision molded battery cases, valve components, and food packaging components widely utilize PP because it is strong and has a smooth surface finish.

- Mill Lead Time: Up to 3 days

- Color: White with a glossy finish

PE

Polyethylene is also chemical-resistant, tough, and flexible, qualities all needed to High Precision Injection Molding applications. It is effective in producing resilient parts with moderate complexity. PE is highly utilized in fabricating storage boxes, piping fittings, and protective covers. For instance, precision-molded home accessories, tubing fittings, and guard shields benefit from PE’s precise performance and exact dimensional accuracy.

- Mill Lead Time: Up to 3 days

- Color: Translucent natural

PS

Polystyrene is of higher clarity, rigidity, and processability, hence a commodity plastic with extensive versatility to High Precision Injection Molding. Its detail retention is optimum when appearance and dimensional tolerances are critical. PS is commonly used in precision packaging, display components, and electronic enclosures. For example, complex retail display components, accurate prototype models, and electronic end components often use PS to achieve a smooth, clean finish.

- Mill Lead Time: Up to 4 days

- Color: Clear, with a subtle shine

PVC

PVC is most desirable due to its strength, fire resistance, and ease of moulding in injection moulds. PVC finds extensive application in fittings, accessories for cars, and construction materials. For example, the majority of window profiles and interior trim parts are manufactured using PVC due to its superior strength and color modification ability.

- Mill Lead Time: Up to 2 days

- Color: White or grey, with a smooth finish

ABS

ABS possesses the desired properties for High Precision Injection Molding due to its balanced moldability, impact strength, and toughness. Its excellent dimensional stability makes it easy to mold complex geometries and fine details. ABS is a key material employed in automotive dashboards, electronic enclosures, and parts for domestic appliances. For example, fine interior panel trim pieces, control panel covers, and fine casings are manufactured with ABS in order to achieve a smooth look and tight tolerances.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PC

Polycarbonate (PC) is an excellent engineering plastic suitable for High Precision Injection Molding because of high impact strength, optical clarity, and excellent thermal resistance. It is capable of producing complex and hard parts, which are ideal for vital applications. PC is used in electronic enclosures, safety devices, and optical components. For example, precision molded display case covers, clear sheets, and display cases make use of PC because it is hard and has a transparent appearance.

- Mill Lead Time: Up to 2 days

- Color: Clear with UV-resistant coating

PA

Polyamide (Nylon) is enhanced for High Precision Injection Molding by higher mechanical strength, wear resistance, and thermal stability. The satisfactory flow and low friction of Nylon make it applicable in the production of precise, durable products. Automobile gears, bearings, and intricately designed consumer products are typical examples of Nylon usage. As an illustration, gear assemblies with precise tolerances, long-lasting connector housings, and robust mechanical components value Nylon’s retention of tight tolerances.

- Mill Lead Time: Up to 3 days

- Color: Off-white with a matte finish

POM

Polyoxymethylene or POM possesses high dimensional stability, low friction, and stiffness, making it suitable for High Precision Injection Molding. Its fine detailing capability is crucial in parts with fine surfaces and close tolerances. POM typically applies to gears, bushings, and intricate mechanical components. Automotive transmission parts, high-tolerance fasteners, and precision valve components, for instance, use POM commonly due to its reliability.

- Mill Lead Time: Up to 4 days

- Color: Natural, slightly translucent

PEEK

PEEK is an upscale material for High Precision Injection Molding, renowned for its extremely high mechanical strength, chemical resistance and high temperature stability. It is used in extremely demanding applications in engineering where performance is of the highest significance. PEEK is utilized in far-reaching fields of aerospace, medical and automobile industries. High tolerance formed medical components, high stress engine components, and very critical aerospace fittings adopt PEEK’s ability to hold extremely good tolerances under stresses.

- Mill Lead Time: Up to 5 days

- Color: Natural amber with a polished finish

PEI

Polyetherimide (PEI) is highly valued for its high thermal stability, flame retardance, and good precision when formed, which are specifically well-suited to High Precision Injection Molding. Its strong nature provides dependability in intricate, high-end applications. PEI is applied in advanced electronics, aerospace interior components, and automotive parts. For example, precision molded cockpit panels, electrical enclosures, and high-quality connector housings make heavy use of PEI due to its homogeneity and smooth surface.

- Mill Lead Time: Up to 4 days

- Color: Translucent cream with a matte finish

PPSU

Polyphenylsulfone (PPSU) is highly resistant, heat-resistant, and dimensionally stable, a fact that makes it ideal for High Precision Injection Molding for critical applications.

PPSU is excellent when subjected to long-term high temperature and chemical exposure. PPSU is widely utilized in medical devices, plumbing fixtures, and precision automotive parts. Extremely small medical connectors, heavy-duty water fittings, and extremely detailed automotive components utilize the excellent detail retention of PPSU.

- Mill Lead Time: Up to 5 days

- Color: Deep brown with a smooth texture

Finishing Options for High Precision Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Metal, Plastic | — | Buffing, Tumbling, Vibratory Polishing |

|

Anodizing | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Electroplating | Steel, Copper, Zinc | Chrome, Gold, Silver | Electroplating Bath |

|

Powder Coating | Aluminum, Plastic, Steel | Custom Colors | Spray Application |

|

Laser Etching | Metal, Plastic | — | Laser Machines |

|

Chem Film | Aluminum, Stainless Steel | Clear, Gold | Media Blasting, Tumbling, Anodizing |

|

Bead Blasting | Metal, Plastic | — | Sandblasting, Abrasive Blasting |

|

Silk Screening | Plastic | Multiple | Manual or Automated Process |

|

Vibratory Finishing | Aluminum, Stainless Steel | — | Vibratory Tumbling |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your High Precision Injection Molding Supplier Selection Ultimate Guide

Which high precision injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo High Precision Injection Molding

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What is your minimum order quantity?

Our MOQ can be negotiated, but in the case of a typical injection molding job, we start at 100 pieces.

How soon can you ship?

We send out standard orders 5-10 business days, with overnight shipping as an option.

Can I order a sample order before bulk purchasing?

Yes, we offer sample production to demonstrate our quality meets your expectations.

Do you take custom designs?

Yes, we work with you from initial conception right up to final manufacture in order to enable your unique design needs.

What are you certified to?

Our suppliers are ISO certified, of high standards and consistently high quality.

What are your payment terms?

We offer competitive payment terms, usually a deposit with the balance upon shipment.

High Precision Injection Molding Resource

Are You Looking for High Precision Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.