Gas-Assisted Injection Molding Services

Formioo offers gas-assisted injection molding services for complex, hollow, and thick-walled plastic parts. We ensure reduced part weight, shorter cycle times, and excellent surface quality with fast delivery.

- 10+ years of experience in gas-assisted molding

- 50+ Certified Materials & 15+ Surface Finishing Options

- The standard tolerance is controlled within ±0.1 mm

- Full Engineering Support

Reliable Gas-Assisted Injection Molding Manufacturer from China

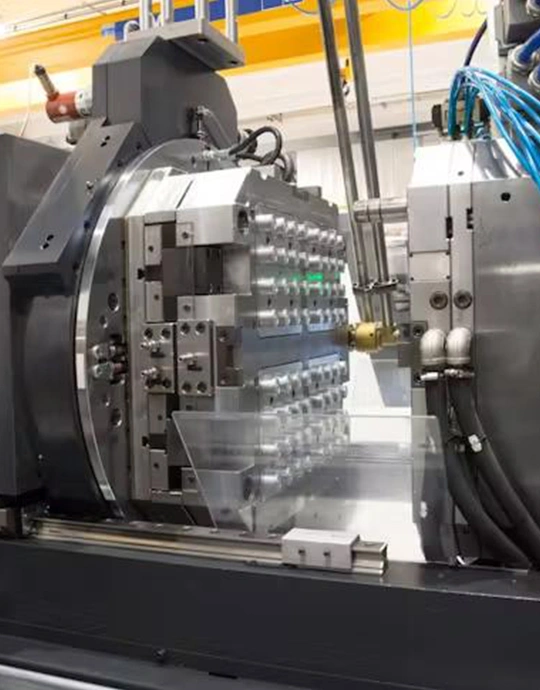

Formioo is a professional gas-assisted injection molding service provider based in China, focused on producing complex, hollow, and thick-walled plastic components with enhanced structural performance and cosmetic quality. We utilize state-of-the-art gas injection equipment to support both functional prototyping and low-to-mid volume production.

Our gas-assisted molding process enables reduced material usage, minimized warpage, and the elimination of sink marks, making it ideal for parts that require high rigidity with lower weight. With in-house DFM support and strict quality control, we help clients shorten development cycles and avoid costly design revisions.

Since 2016, Formioo has been delivering precision gas-assisted molded parts to global clients in the automotive, home appliance, consumer electronics, and industrial sectors. Backed by years of production expertise, we offer flexible batch sizes and responsive turnaround for even the most challenging geometries.

Our Gas-Assisted Injection Molding Services

Formioo offers comprehensive gas-assisted injection molding capabilities, including Direct GAIM, Indirect GAIM, Sequential GAIM, and Co-injection GAIM. These techniques allow us to create complex parts with hollow sections, thicker ribs, and large surfaces while minimizing warpage, sink marks, and internal stress. We support a wide selection of thermoplastics, such as ABS, PC, PC/ABS, HDPE, PA, and reinforced engineering plastics, tailored to meet your functional and structural requirements.

To enhance performance and aesthetics, we offer a range of surface treatment options, including texturing, painting, chrome plating, and silk screening. Our production facilities can achieve tight dimensional tolerances of ±0.01 mm for gas-assisted molded components. Every part undergoes rigorous quality checks using precision measurement tools like CMMs and optical scanners to ensure consistency and accuracy from prototype to production.

In Direct GAIM, high-pressure inert gas is injected directly into molten plastic, forming hollow channels to reduce weight.

Indirect GAIM introduces gas via dedicated channels beside the melt, ensuring controlled cavity formation and smooth surfaces.

Sequential GAIM uses multiple gas injections to optimize internal structure and balance wall thickness for strength.

Co-injection GAIM simultaneously injects plastic and gas, integrating hollow sections for uniform material distribution and weight reduction.

Gas-Assisted Injection Molding Capabilities

Material Compatibility

Our capable of molding engineering plastics (ABS, PP, PC, POM, Nylon, etc.), meeting various industrial and custom production needs.

Printing Accuracy

Our standard tolerance controlled within ±0.1mm, ensuring high precision for complex geometries and hollow structures.

Maximum Build Size

Our maximum part size up to 500mm × 500mm × 300mm, suitable for small to medium-sized components.

Surface Finishing Options

We support polishing, painting, texture finishing, and more for enhanced durability and aesthetics.

Delivery Time

Our standard molding lead time is 7-14 days, with expedited service available for urgent projects.

Massive Network

We work with trusted injection molding suppliers.

Explore Gas-Assisted Injection Molding Parts We Manufactured

Explore our precision-engineered Gas-Assisted Injection Molding parts and see the quality for yourself. From prototyping to mass production, our high-performance components meet the toughest industry standards.

Gas-Assisted Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Gas-Assisted Parts | +/- 0.3 mm to +/- 0.5 mm |

| Precision Gas-Assisted Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Gas-Assisted Parts | +/- 0.3 mm to +/- 0.6 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Gas-Assisted Injection Molding Materials

PP

Polypropylene is well suited for Gas-Assisted Injection Molding as it has good melt flow, chemical resistance, and lightness. It contains built-in flexibility that is ideally appropriate for gas penetration with effectiveness, providing wall thickness and product lightness. Polypropylene is used in the manufacture of complex parts such as motor structural components, home appliance casings, packaging containers, and light furniture. Gas-assisted molding with PP produces intricate hollow sections most ideally used for door panels, trays, and other high-volume production parts where precision and consistency are the essential factors.

- Mill Lead Time: Up to 3 days

- Color: Natural white, customizable

HDPE

HDPE finds special suitability in Gas-Assisted Injection Molding with its excellent strength, rigidity, and chemical resistance. It provides good flow characteristics for the creation of structures with low sink marks and low material consumption. HDPE is also commonly utilized in molding heavy-duty storage tanks, piping systems, industrial coverings, and protective coverings. In gas-assisted, it also molds light-weighted parts such as large containers and complex architectural components wherein dimensional stability is vital.

- Mill Lead Time: Up to 4 days

- Color: Natural, various pigments available

PS

Polystyrene has been extensively applied in Gas-Assisted Injection Molding due to the fact that it is transparent, easy to process, and cost-effective. Its low viscosity allows easy production of hollow products and saves material. PS finds widespread applications in the manufacturing of consumer electronics cases, disposable cutlery, packaging items, decorative panels, and lighting fixtures. The PS gas-assisted processes also produce teaching aids and high-quality design components with uniform wall thickness and good surface finishes at high-volume production.

- Mill Lead Time: Up to 3 days

- Color: Clear, translucent options

PVC

The rigidity, chemical resistance, and flexible formulation of PVC make it well-suited for Gas-Assisted Injection Molding. Its enhanced flow ensures it is possible to manufacture complex, hollow products with even wall thickness and reduced weight. PVC is utilized extensively in molding of pipes, window profiles, electrical conduits, trim components of the automobile, ornamental fittings, and household fixtures. Gas-assisted molding using PVC produces complex geometries and fine details required for functional and appearance factors in modern construction and consumer products.

- Mill Lead Time: Up to 4 days

- Color: White, grey, customizable

ABS

ABS is especially well-fitted for Gas-Assisted Injection Molding since it has such fantastic impact strength, toughness, and moldability. Its flowability is so great that it can make thin, hollow parts with low weight but no loss of strength. ABS is applied extensively in the automotive dashboard, electronic enclosures, consumer product cases, instrument panels, and office machine casings. Gas-assisted processing enables ABS to make intricate designs and close tolerances in products where the strength and looks are important considerations.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PC

Polycarbonate has more optical clarity, impact resistance, and thermal stability, and therefore is the best material to utilize in Gas-Assisted Injection Molding. It has a greater melt flow to produce thin-walled, complex structures with exceptional strength. PC is extensively used in light protective covers, electronic display units, complex auto components, and transparent enclosures. In gas-assisted technologies, PC offers parts with greater dimensional stability and reduced weight, as is ideal for high-end instrument panels and consumer electronics.

- Mill Lead Time: Up to 5 days

- Color: Clear, tinted variants available

PA

Nylon is highly sought after in Gas-Assisted Injection Molding due to its excellent mechanical properties, wear life, and self-lubricity. Its favorable melt flow permits the production of complex, hollow parts with constant wall thickness and enhanced strength. Nylon is used in large quantities in gears, bearing housing, under-hood auto components, precision molded connectors, and fasteners. Gas-assisted processing optimizes its dimensional stability and minimizes production cycles, hence it is an excellent choice for use in performance- and durability-critical applications.

- Mill Lead Time: Up to 5 days

- Color: Natural, black, and custom options

POM

POM is inherently well adapted to Gas-Assisted Injection Molding due to its sufficient stiffness, low friction behavior, and favorable dimensional stability. Its satisfactory flow properties ensure it can be easily molded into hollow components with little warpage. POM is used in precision gears, automotive fuel system components, electrical connectors, and intricate valve housings. The gas-assisted process enables it to perform well in complex geometries with uniform strength and quality, and it is ideal for mechanical components and pump components with high performance.

- Mill Lead Time: Up to 4 days

- Color: Natural, pigmented options available

PEEK

PEEK is one of the most suitable materials for Gas-Assisted Injection Molding as it possesses superior high-temperature resistance, chemical inertness, and mechanical strength. Its difficult melt flow enables the formation of complex, hollow geometries with minimal defect and is most apt for aerospace, automotive, and medical applications. PEEK finds application in structural components, fluid transfer systems, low-mass heat exchangers, pump housings, and precision fittings. Gas-assisted molding performs at its best under harsh conditions, possessing high reliability and life in critical, high-stress applications.

- Mill Lead Time: Up to 7 days

- Color: Natural, customizable

PPS

PPS is renowned for having excellent dimensional stability, resistance to chemicals, and thermal stability and is therefore highly suitable for Gas-Assisted Injection Molding. Its stable flow behavior makes it possible to produce complex, hollow structures with improved surface finish and retention of strength at high temperatures. PPS is commonly applied in electronic parts, automotive under-hood parts, industrial enclosures, and sensor casing. Gas-assisted molding allows for the production of circuit breaker housings, performance fittings, and complex devices that require precision and strength.

- Mill Lead Time: Up to 6 days

- Color: Grey, standard variants

LCP

LCP is also very well suited to Gas-Assisted Injection Molding because of its unique molecular orientation, which gives it excellent dimensional stability and mechanical properties. It can be used to form intricate hollow structures with good thermal resistance because it has a high flow rate and quick crystallization. LCP has widespread uses in high-frequency electronic components, precision connectors, automotive sensor housing, microfluidic devices, and complex circuit boards. Gas-assisted technologies make LCP achieve high precision and uniformity in small-scale systems.

- Mill Lead Time: Up to 6 days

- Color: Natural, various shades

PEI

PEI is the only one with high heat resistances, mechanical strengths, and inherent flame retardancy in Gas-Assisted Injection Molding. Its flow characteristics help in the development of intricate, empty components with improved accuracy and reduced weight. PEI is widely applied in electrical connectors, aircraft parts, medical devices, instrument panels, and communication enclosures. Gas-assisted processing further has the ability to form thin-walled complex structures with the best stability, thus being most ideal for high-end, high-performance applications.

- Mill Lead Time: 4–5 days

- Color: Natural, White, or Customizable

Finishing Options for Gas-Assisted Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Plastic, Metal | — | Buffing, Tumbling |

|

Anodizing | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Powder Coating | Aluminum, Plastic | Custom Colors | Spray Application |

|

Electroplating | Steel, Copper, Zinc | Chrome, Gold, Silver | Electroplating Bath |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

|

Laser Etching | Plastic, Metal | — | Laser Machines |

|

Bead Blasting | Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

UV Coating | Plastic | Glossy, Matte | UV Curing Process |

|

Silk Screening | Plastic | Multiple | Manual or Automated Process |

|

Vibratory Finishing | Plastic, Metal | — | Vibratory Tumbling |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Gas-Assisted Injection Molding Supplier Selection Ultimate Guide

Which gas-assisted injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Gas-Assisted Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What Gas-Assisted Injection Molding is able to process?

Any thermoplastics like ABS, polycarbonate (PC), polypropylene (PP), and polyamide (PA), etc., can be processed by Gas-Assisted Injection Molding.

Do you provide assistance in part design and optimization for Gas-Assisted Injection Molding?

Yes, Formioo offers complete engineering and design support. Our experts can help in part design optimization to take advantage of the Gas-Assisted Injection Molding process with efficiency and cost-effectiveness.

In which industries can Gas-Assisted Injection Molding be beneficial?

Automotive, consumer electronics, medical devices, packaging, and aerospace applications will be optimally served by the cost-saving and efficient production features of Gas-Assisted Injection Molding.

What is typical lead time for manufacturing of Gas-Assisted Injection Molding?

Lead times will vary depending on the type of project, but typically prototypes can be made in 2-4 weeks and production quantities in 4-6 weeks. Rapid prototyping is also offered for urgent product creation.

How does Formioo ensure the quality and accuracy of its molded parts?

We also have high quality ISO standards here at Formioo. We use the most current simulation and molding technology to deliver the highest accuracy, so each part is exactly to specification and tolerance.

What is the minimum order quantity (MOQ) for Gas-Assisted Injection Molding?

Minimum order quantity will depend on the complexity of the part and mold design. However, we have accommodative arrangements to facilitate small batch production as well as large scale manufacturing needs.

Gas-Assisted Injection Molding Resource

Are You Looking for Gas-Assisted Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.