Manufacturing on Demand for the Electrical Industry

Formioo delivers high-quality, on-demand electrical injection molding manufacturing services. The fastest mold guarantee in 5 days.

- 10+ years of experience in electrical injection molding services

- Precision Electrical Injection Molding with tolerances as tight as ±0.01 mm

- 50+ Certified Materials & 15+ Surface Finishing Options

- 24/7 engineering support

One-Stop Electrical Injection Molding Solutions Provider from China

Formioo is a professional electrical injection molding manufacturer in China, providing rapid prototyping and mass production of precision plastic components for the electrical industry. With in-house mold design, high-speed injection machines, and high-quality material sourcing, we ensure fast turnaround and consistent part quality for both low and high-volume orders.

Our experienced engineering team offers complete DFM analysis, mold flow simulation, and material recommendations to help clients design parts that meet insulation, flame retardancy, and dimensional stability requirements. We specialize in insert molding and overmolding for complex electrical components such as switch housings, terminal blocks, sensor covers, and insulating sleeves, ensuring safety, performance, and regulatory compliance.

With over 10 years of manufacturing experience, Formioo delivers tens of thousands of electrical-grade parts each year to clients across power systems, automation equipment, energy storage, and electrical control industries. Whether you are developing a new product or scaling up for mass production, we offer flexible, cost-effective solutions to meet your technical and timeline needs.

What kind of electrical injection molding parts can we make?

Formioo manufactures a wide range of injection-molded plastic parts for electrical applications, including switch housings, terminal blocks, fuse holders, cable glands, insulating bushings, circuit protection components, and sensor enclosures. We work with flame-retardant and high-dielectric strength materials such as PA66 (with glass fiber), PBT, PC, PPS, and certified engineering plastics to ensure electrical insulation, heat resistance, and mechanical stability.

To meet the demanding requirements of the electrical industry, we employ advanced injection molding techniques, including insert molding, overmolding, and multi-cavity tooling. We also offer post-molding services such as ultrasonic welding, laser marking, and precision assembly. Our production supports tight tolerances down to ±0.01 mm, and all parts are subject to strict quality control using automated CMM and visual inspection systems. We also provide surface finishes such as matte textures, custom color matching, and EMI shielding where needed, ensuring each part performs reliably in both low-voltage and high-voltage environments.

- Electronic Housings

- Sensor Enclosures

- Control Panel Casings

- Connector Components

- Switch and Button Casings

- LED Light Housings

- Battery Casings

- Cable Management Solutions

- Heat Sink Enclosures

- Fuse and Relay Housings

Electrical Injection Molding Capabilities

Material Compatibility

We injection mold high-performance engineering plastics such as ABS, PP, PC, and Nylon to meet diverse industrial needs.

Printing Accuracy

Having close tolerances of ±0.01 mm to ensure uniform quality.

Maximum Build Size

Capable of producing components suitable for small to medium-sized parts.

Surface Finishing Options

Supplying painting, plating, polishing, and texturing for additional esthetics and durability.

Delivery Time

5-10 day standard lead times, with rush production for rush orders.

Massive Network

We work with trusted injection molding suppliers.

Our Latest Electrical Injection Molding Creations

Explore our expertly crafted injection molded components and witness superior quality firsthand. From initial prototypes to high-volume production, our partner network delivers precision and excellence you can trust.

Electrical Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Electrical Parts | +/- 0.2 mm to +/- 0.5 mm |

| Precision Electrical Parts | +/- 0.05 mm to +/- 0.2 mm |

| Complex Electrical Parts | +/- 0.3 mm to +/- 0.8 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

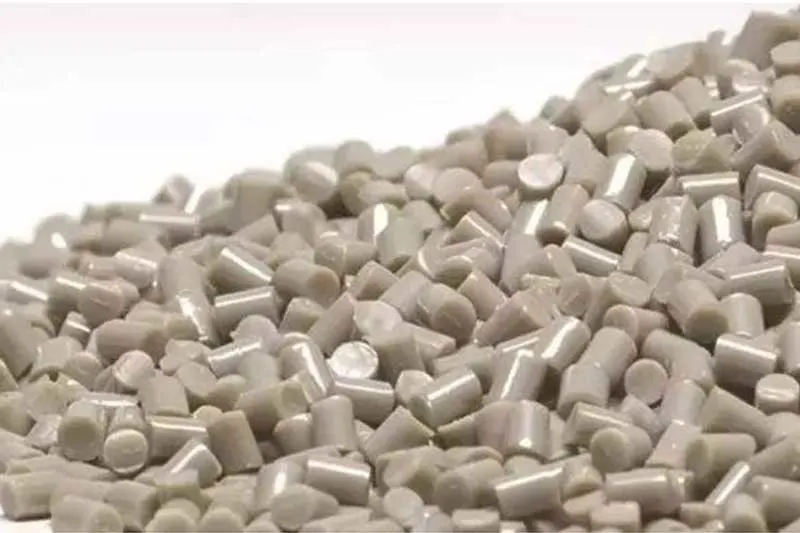

Electrical Injection Molding Materials

pp

PP is particularly suited for Electrical Injection Molding due to its chemical resistance, low weight, and cost. Its high flow properties enable the production of light and tough components. PP has extensive applications in switch bases and sensor enclosures and hence is used extensively in electric mass-produced components.

• Mill Lead Time: Up to 3 days

• Color: Natural white, customizable

ABS

ABS is ideal for Electrical Injection Molding because of its excellent mechanical properties, impact resistance, and smooth flow. It allows for precise molding of complex shapes and is widely used for electronic housings and control panel components. For example, many consumer electronics enclosures are produced using ABS for its strength and detail retention.

• Mill Lead Time: Up to 3 days

• Color: Black, neutral matte finish

PC

Polycarbonate is the choice for Electrical Injection Molding because of its higher impact strength, clarity, and thermal resistance. It is best for the manufacture of transparent LED enclosures, protective screens, and instrument panels where function and looks are a requirement. Its heat resistance makes it a reliable option in harsh applications.

• Mill Lead Time: Up to 3 days

• Color: Transparent, custom options

PA

Nylon offers great wear resistance, low friction, and chemical stability and therefore is a resilient choice for Electrical Injection Molding. It is used extensively for production of connectors, gear housing, and cable management components where toughness and steady performance under stress are required.

• Mill Lead Time: Up to 3 days

• Color: Natural, customizable

PEEK

PEEK is a high-temperature performance polymer that exhibits excellent thermal stability, chemical resistance, and strength. In Electrical Injection Molding, PEEK is used in mission-critical aerospace and medical device parts needing high reliability and accuracy in extreme environments.

• Mill Lead Time: Up to 5 days

• Color: Natural, off-white, or custom

PEI

PEI is also widely renowned for its superior flame retardancy, dielectric insulation, and heat resistance. Its toughness makes it an excellent selection for high-voltage connectors, circuit breaker enclosures, and other heavy-duty electrical devices in which performance and reliability are prime considerations.

• Mill Lead Time: Up to 5 days

• Color: Natural amber, customizable

Finishing Options for Electrical Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum, Stainless Steel, Copper | Clear, gold | Media Blasting, Tumbling, Type II Anodizing, Type III Anodizing with PTFE |

|

Powder Coating | Aluminum, Steel, Plastic | Wide range (depending on powder) | Electrostatic Spray, Curing Oven |

|

Anodizing | Aluminum, Titanium | Clear, Black, Custom | Electrolytic Process |

|

Polishing | Aluminum, Stainless Steel, Copper | Glossy, Smooth | Polishing Wheels, Buffing Compounds |

|

Electroplating | Aluminum, Steel, Copper | Silver, Chrome, Gold, etc. | Electrolytic Process |

|

Laser Etching/Marking | Aluminum, Steel, Plastic | Natural, Black | Laser Machines |

|

Vibratory Finishing | Aluminum, Steel, Stainless Steel | Matte, Metallic | Vibratory Tumblers |

|

Brushing | Stainless Steel, Aluminum | Natural metallic finish | Abrasive Brushes, Mechanical Buffing |

|

Surface Sealing | Aluminum, Plastic, Copper | Clear, Glossy | Surface Sealing Coating |

|

UV Coating | Plastic, Metal | Clear, Glossy | UV Curing Lamps, Coating Equipment |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Electrical Injection Molding Supplier Selection Ultimate Guide

Which electrical injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Electrical Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What kinds of product are electric injection molding able to produce?

They’re ideally suited to high-accuracy, thin-walled, or small-sized parts, such as medical equipment, electronic components, and optical lenses. If your item demands close tolerances, electric machines would be most suitable.

Are electric injection molding suitable for mass production?

Yes, they are! Electric machines are extremely stable and designed for continuous use and are thus suited to high-volume, high-grade production.

What level of after-sales service do you offer for electric injection molding?

We provide from installation to training, maintenance, and rapid-response repair, so that your production is never interrupted.

How is the lead time?

Our normal lead time is 3 to 5 days, with expedited service for urgent projects.

Do you offer design support?

Yes, we do provide design support to help you design your components for the best manufacturing result.

How do I get a quote?

Just complete our online form or phone us, and we’ll give you a prompt, no-obligation quote.

Electrical Injection Molding Resource

Are You Looking for Electrical Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.