Custom Die Casting Services

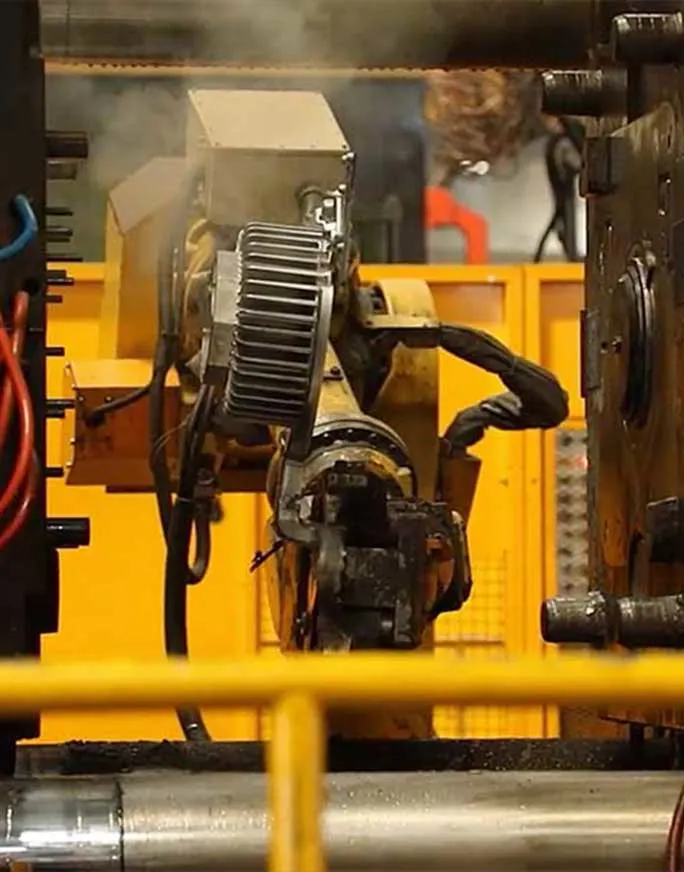

Formioo uses the latest die casting machines and technologies to provide high-quality on-demand parts with tight tolerances, excellent surface quality, and fast lead times to various industries.

- Precision Die Casting with tolerances as tight as ±0.01mm

- Large range of materials such as Aluminum, Zinc, and Magnesium alloys

- Variety of surface finishing such as anodizing, powder coating, and shot blasting

- Technical support on design and manufacturing

- Samples as fast as10-15 days

One-stop Die Casting Solution Provider from China

Formioo is a professional die casting manufacturer in China, offering end-to-end solutions for aluminum, zinc, and magnesium alloy components. Our facility is equipped with advanced hot and cold chamber die casting machines, in-house tooling, CNC post-machining, and finishing lines, allowing us to handle both prototype development and large-scale production with consistent quality and precision.

Our die casting services are designed to help customers overcome challenges such as thin-walled parts, complex geometries, high-strength requirements, and tight tolerance demands. We provide full engineering support, including DFM (Design for Manufacturability), mold flow analysis, and custom alloy recommendations—ensuring your parts meet both performance and cost targets. We also offer integrated secondary services like trimming, drilling, tapping, surface finishing, and assembly, simplifying your supply chain.

With over 10 years of experience in precision metal casting, Formioo delivers hundreds of thousands of die-cast parts annually to clients in automotive, electronics, medical devices, lighting systems, and industrial machinery. Whether you’re launching a new product or scaling up volume production, we offer responsive service, short lead times, and stable quality at every stage of your die casting project.

Explore Our Die Casting Capabilities

Formioo offers comprehensive die casting capabilities, including High-Pressure Die Casting (HPDC), Low-Pressure Die Casting (LPDC), Gravity Die Casting, and Vacuum Die Casting. These processes enable us to produce high-precision, complex metal parts with excellent strength, dimensional stability, and repeatability. We work with a wide range of non-ferrous metals, primarily aluminum alloys (e.g. A380, ADC12, AlSi10Mg), zinc alloys (e.g. Zamak 3, Zamak 5), and magnesium alloys, to meet specific performance and weight requirements across industries.

To enhance both appearance and functionality, we provide multiple surface finishing options such as shot blasting, powder coating, anodizing, e-coating, chromate conversion, and CNC post-machining. Depending on the casting process and material, we achieve tolerances as tight as ±0.01 mm for critical features. All parts undergo dimensional inspections using tools like CMMs and X-ray testing to ensure internal and external quality compliance for end-use applications.

Forces molten metal into a mold under high pressure, ideal for mass production.

Using low pressure to push molten metal into the mold, for thin-walled parts.

Relies on gravity to fill the mold with molten metal, used for medium to small batch production.

Casts metal under a vacuum to reduce air pockets, improving part density and quality.

Die Casting Capabilities

Material Compatibility

We machine various materials including aluminum, zinc, magnesium alloys, and copper to suit the diverse requirements of industries.

Printing Accuracy

Our die casting precision is maintained at ±0.01mm to create high-quality, reliable parts for automotive, electronic, and industrial applications.

Maximum Build Size

We can handle casting sizes up to 500mm × 500mm × 300mm, suitable for both small and medium-scale parts.

Layer Thickness Range

Thickening of layers, typically 0.1mm - 0.3mm, variable printing speed vs. detail accuracy.

Delivery Time

We offer a range of finishes like anodizing, powder coating, polishing, and shot blasting to improve durability and appearance.

Massive Network

We work with trusted die casting suppliers.

Explore Die Casting Parts We Manufactured

See our high-quality die casting parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Die Casting Tolerance

| Name | Tolerance Range |

|---|---|

| Tolerance Range | +/- 0.5 mm to +/- 1.0 mm |

| Precision Die Castings | +/- 0.2 mm to +/- 0.5 mm |

| Complex Die Castings | +/- 1.0 mm to +/- 2.0 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Die Casting Materials

Aluminum alloys

Aluminum alloys are particularly well-adapted for Die Casting due to their great strength, low weight, and better corrosion resistance. They are extensively utilized in the auto, aerospace, and electronics markets. Aluminum die-cast items like engine blocks, transmission cases, and automobile wheels, for example, utilize their light weight and strength, reducing vehicle weight and providing strength. Aluminum alloys are utilized in heat sinks and electrical enclosures where high thermal conductivity is required. Their high performance and versatility are reasons they are among the top demanded Die Casting materials.

- Mill Lead Time: As fast as 7-10 days

- Finishes: Raw, anodized, powder coated, bead blasted, polished

Zinc alloys

Zinc alloys have very wide usage in Die Casting due to their superior castability, good strength, and dimensional stability. These alloys are suitably applied in producing small-sized components with finer details. Zinc die-casting items have extensive application in the electronic sector, automobile components, and household consumer appliances such as connectors, switches, and enclosures. Zinc alloys are typically characterized by the method of creating smooth surface areas and excellent wear resistance, coupled with corrosion resistance. They are most commonly used where tight tolerances and high precision finishes are required, and are thus essential in items such as gears, locks, and handles.

- Mill Lead Time: As fast as 5-7 days

- Finishes: Raw, electroplated, powder coated, polished

Magnesium Alloys

Magnesium alloys are normally used on Die Casting on the basis of strength-to-weight ratio. Magnesium alloys are utilized in those applications where saving weight is highest, i.e., automobile and aerospace. Trim interior of motor engine blocks and lightness are possible due to magnesium die-casting parts because they weigh less but are strong. Magnesium alloys find their usage in power tools, sport equipment, and electronics where there is a need for lightness as well as strength. While magnesium alloys are highly resistant to corrosion, caution should be exercised while handling them while casting to avoid oxidation and for quality output.

- Mill Lead Time: As fast as 10-12 days

- Finishes: Raw, anodized, shot blasted, polished

Copper Alloys

Copper alloys, having high electrical and thermal conductivity, are best utilized in Die Casting where high heat dissipation and electrical conductance are needed. Copper alloys have large-scale applications in electronics, power transmission, and vehicle use. For example, copper die-casting components are utilized in connectors, electric terminals, and heat exchangers. Copper alloys also have high wear resistance, appropriate for high-stress components like gears and bearings. They are beneficial where thermal management comes into play due to their strength at high temperatures.

- Mill Lead Time: As fast as 7-10 days

- Finishes: Raw, electroplated, polished, brushed

Lead alloys

Lead alloys are used most frequently in Die Casting due to their high density and castability. Although use of lead has fallen owing to environmental issues, it is still required in some special purposes like shielding against radiation and batteries. Lead die-cast parts, for example, are still used in lead-acid automobile batteries as well as in medical imaging shielding. Lead alloys have high castability and are highly corrosion-resistant under specific conditions, but otherwise are used only for specialist applications where their particular properties are necessary.

- Mill Lead Time: As fast as 7-10 days

- Finishes: Raw, electroplated, polished

Finishing Options for Die Casting

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum, Zinc, Magnesium | Clear, gold | Media Blasting, Tumbling, Type II Anodizing, Type III Anodizing with PTFE |

|

Powder Coating | Aluminum, Zinc, Magnesium, Steel | Wide range (depends on powder) | Electrostatic Spray, Curing Oven |

|

Anodizing | Aluminum | Clear, Black, Custom | Electrolytic Process |

|

Polishing | Aluminum, Zinc, Magnesium | Bright, Mirror-like finish | Polishing Wheels, Buffing Compounds |

|

Electroplating | Aluminum, Zinc, Steel | Silver, Chrome, Gold, etc. | Electrolytic Process |

|

Vibratory Finishing | Aluminum, Zinc, Magnesium, Steel | Matte, Metallic | Vibratory Tumblers |

|

Chromate Conversion Coating | Aluminum, Zinc | Clear, Yellow, Olive Drab | Chemical Bath |

|

Laser Etching/Marking | Aluminum, Zinc, Steel | Natural, Black | Laser Machines |

|

Galvanizing | Steel | Silver, Metallic | Hot-Dip Galvanizing, Electroplating |

|

Brushing | Aluminum, Stainless Steel | Natural metallic finish | Abrasive Brushes, Mechanical Buffing |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Die Casting Supplier Selection Ultimate Guide

Which die casting supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Die Casting Manufacturing FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What can you use to produce Die Castings?

We produce Die Castings in a vast array of materials, from aluminum, zinc and magnesium, to copper and beyond, depending on your needs for application.

What is the Die Casting minimum order quantity (MOQ)?

Our minimum order quantity is 100 pieces, but we will accept small and large orders according to your requirement.

How fast can I get my Die Casting parts?

Our typical lead time is 7-10 days for prototypes and 15-20 days for mass production, depending on the complexity.ial through our custom RFQ process.

Can you provide surface finishes for Die Cast parts?

Yes, we do have various finishes like anodizing, electroplating, powder coating, and bead blasting, depending on the need of your part.

Which markets do you serve?

We serve automotive, electronics, aerospace, medical device, and consumer goods markets, providing high-quality Die Cast parts for all uses.

How do you ensure the quality of Die Cast components?

We employ cutting-edge inspection tools and techniques such as measurement of size, material testing, and surface quality test to ensure that every component meets your standards.

Die Casting Resource

Are You Looking for Die Casting Supplier in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.