Custom Compression Molding Services

Formioo offers flexible compression molding services with low minimum order quantities, fast lead times, and scalable production.

- Rapid prototype as far as 2 days

- Suitable for high- and low-volume production

- 50+ Material Certifications & 15+ Surface Finishing

- Low-cost prototyping & mass production capabilities

- 24/7 engineering support

Reliable Compression Molding Manufacturer from China

Formioo is a custom compression molding services provider for thermoset and composite parts. With in-house mold making, temperature-controlled press systems, and rapid tooling capabilities, we support fast prototyping and low-to-medium volume production of high-strength molded components.

Our compression molding process is ideal for large, structurally complex, or heat-resistant parts with excellent repeatability and low material waste. We provide DFM (Design for Manufacturability) support to help clients solve common challenges such as inconsistent fiber orientation, incomplete curing, surface defects, or underfill issues—ensuring part integrity and optimal mold performance from the first run.

Since 2016, Formioo has delivered compression molded parts to customers across the automotive, aerospace, medical, consumer electronics, and industrial equipment sectors. Our flexible order quantities, short lead times, and ability to work with BMC, SMC, phenolics, and advanced composites make us a dependable partner for both prototype development and production-grade supply.

Our Compression Molding Services

Formioo offers a full range of compression molding solutions, including Traditional Compression Molding, Transfer Molding, Prepreg Compression Molding, and Resin Transfer Molding (RTM). These processes allow us to produce high-strength, heat-resistant, and complex-shaped parts with excellent dimensional stability and minimal material waste. We support a wide selection of thermoset and composite materials such as SMC, BMC, phenolic resins, epoxy resins, fiberglass prepregs, and carbon fiber-reinforced compounds—tailored to meet structural, thermal, and dielectric performance requirements.

To meet surface and dimensional expectations, we provide a variety of finishing options, including CNC trimming, post-curing, surface texturing, painting, and coating. Depending on the material and part geometry, our compression molding processes typically achieve tolerances within ±0.01 mm to ±0.1 mm. All parts are thoroughly inspected for voids, fiber orientation, and dimensional consistency to ensure high mechanical integrity and performance in demanding applications.

Heritage compression molding uses heat and pressure to cure a calibrated charge within a closed mold to create high-quality components.

Transfer molding heats a preform and transfers it into a closed mold cavity for creating intricate part geometries.

Prepreg compression molding utilizes pre-impregnated resin and fiber sheets and heats cures under pressure to create composite parts.

Resin transfer molding is a process that injects resin into a dry fiber pre-packed mold, and controlled pressure cures it to yield high-strength parts.

Compression Molding Capabilities

Material Compatibility

Our can mold a number of thermosetting plastics, composites, and elastomers (i.e., phenolic, epoxy, silicone), meeting diversified industry demands.

Printing Accuracy

Our compression molding process is maintained to tolerances as close as ±0.01 mm, offering high dimensional accuracy and consistency.

Maximum Build Size

Our maximum molding size reaches up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Surface Finishing Options

We offer various finishing options, including painting, plating, and texturing for enhanced aesthetics and durability.

Delivery Time

Our standard lead time is 5–10 days, with expedited services available for urgent orders.

Massive Network

We work with trusted compression molding suppliers.

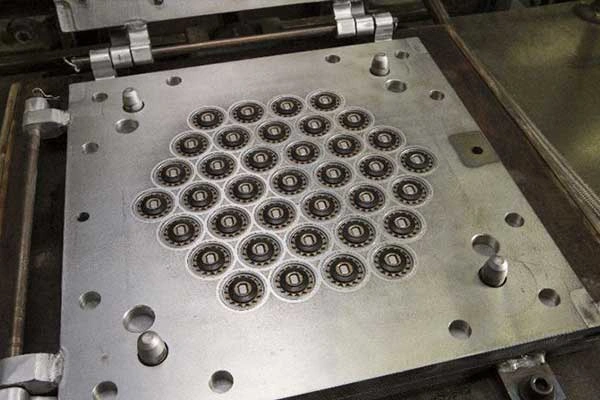

Explore Compression Molding Parts We Manufactured

Explore our precision-engineered compression molded parts and see the quality for yourself. From prototyping to mass production, our advanced compression molding solutions deliver durability and exceptional performance.

Compression Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Compression Molding Parts | +/- 0.5 mm to +/- 1.0 mm |

| High-Precision Compression Molding Parts | +/- 0.2 mm to +/- 0.5 mm |

| Complex Compression Molding Parts | +/- 0.3 mm to +/- 0.6 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Compression Molding Materials

Polyester

Polyester resin is an inexpensive compression molding alternative with ease of processing and good mechanical properties. It is used on automotive body panels, marine components, and other outdoor gear. Its relatively low curing temperature makes it suitable for large-volume, heavy-duty part manufacturing.

- Mill Lead Time: Up to 7 days

- Color: White, black, or custom colors available

ABS

ABS is a versatile commodity plastic with good compression molding properties due to its impact strength, processability, and high strength. It is commonly used in automotive parts, electronic boxes, and consumer goods. ABS is ideal for manufacturing complex parts like dashboards and electronic equipment enclosures.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

Phenolic Resin

Phenolic resin offers superior heat resistance, electric insulation properties, and mechanical strength. It is applied widely in automotive components like brake linings, electrical products like laminates in circuit board, and industrial gears with satisfactory performance under adverse conditions.

- Mill Lead Time: Up to 7 days

- Color: Black, brown, or custom colors available

Epoxy

Epoxy resin is applied due to it having superior strength, chemical resistance, compression molding properties and adhesion. Common applications are utilized for structural components within automobile, aerospace, and electrical applications, such as composite parts and electrical enclosures, for intricate, high-strength applications.

- Mill Lead Time: Up to 10 days

- Color: Transparent, black, or custom colors available

Silicone Rubber

The high-temperature stability, flexibility, and sealability of the rubber render silicone rubber a preferred material for compression molding. It is used in consumer, medical, and automotive applications as gaskets, seals, and O-rings with excellent high-temperature performance.

- Mill Lead Time: Up to 5 days

- Color: Transparent, red, black, or custom colors available

Rubber

Neoprene and nitrile rubber are all-purpose elastomers, weather-resistant, flexible, and chemical-resistant. They are used in vibration dampeners, seals, and gaskets, mainly in heavy-duty industrial and automotive uses where performance and hardness are the main concerns.

- Mill Lead Time: Up to 5 days

- Color: Black, gray, or custom colors available

Fiberglass Reinforced Polyester

Fiberglass-reinforced polyester supplies lightweight, high strength, and impact. It is used in electrical boxes, structural parts, and automobile panels. Fiberglass with polyester resin gives maximum strength with a light-weight design for high-performance application.

- Mill Lead Time: Up to 7 days

- Color: White, black, or custom colors available

Finishing Options for Compression Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Rubber, Plastic, Composite | — | Buffing, Tumbling |

|

Painting | Rubber, Plastic, Composite | Custom Colors | Spray, Dip, or Brush Application |

|

UV Coating | Rubber, Plastic | Glossy, Matte | UV Curing Process |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Anodizing | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Anodizing |

|

Silk Screening | Rubber, Plastic | Multiple | Manual or Automated Process |

|

Laser Etching | Rubber, Plastic | — | Laser Machines |

|

Bead Blasting | Rubber, Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

Surface Texturing | Rubber, Plastic, Metal | — | Mold Texturing, Laser Etching |

|

Vibratory Finishing | Rubber, Plastic, Metal | — | Vibratory Tumbling |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Compression Molding Supplier Selection Ultimate Guide

Which compression molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Compression Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Which are the markets that use Compression Molding?

Compression molding is used in a number of industries like the automobile market, electronics, aerospace, medical devices, and consumer household items for components that need to be high in strength, accuracy, and durability.

What can Compression Molding shape?

We shape a variety of materials, including phenolic, epoxy, silicone rubber, ABS, polyester, and fiberglass-reinforced composites.

How long is the process of Compression Molding?

Lead times are typically 3 to 10 days depending on material, complexity, and quantity. We can offer expediting for rush programs.

Can you handle small runs as well as large volume production?

Yes! We can create small orders of prototypes and high volumes production with high quality at any order.

Is Compression Molding suitable for complex part geometries?

Absolutely! Compression molding is most suitable for producing complex geometries with high accuracy, especially for parts like car parts, seals, and gaskets.

What is Compression Molding's minimum order quantity?

There isn’t strictly a minimum, but there are higher per-unit prices for low-order quantities. We can discuss the best approach based on what you need.

Compression Molding Resource

Are You Looking for Compression Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.