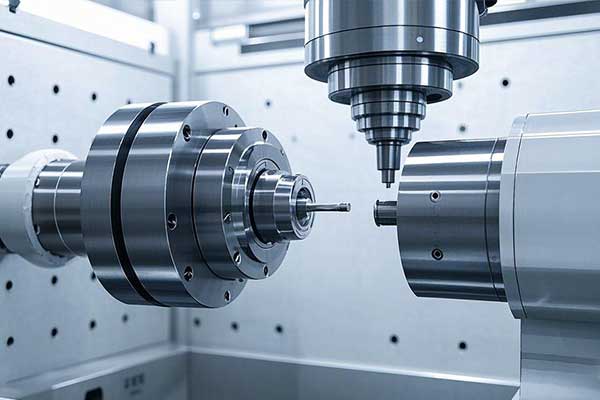

On-demand Custom CNC Machining Services

Formioo offers CNC machining services for rapid prototyping and production parts in metal or plastic. Prototype machining and production parts can be completed in as fast as 5 days.

- One-off CNC Prototypes

- Precision CNC Machining with tolerances as tight as ±0.01 mm

- 100+ plastic and metal materials available

- 10K+ CNC parts made monthly

- Delivery in as quick as 5-7 days

Reliable CNC Machining Manufacturer From China

Formioo is a professional CNC machining manufacturer in China, specializing in high-precision CNC machining of custom metal and plastic parts. Our factory is equipped with advanced 3-, 4-, and 5-axis CNC machines, equipped with both turning and milling capabilities, enabling us to easily handle both prototyping and mass production. All machined parts undergo rigorous dimensional inspection to ensure flawless results.

As a reliable CNC machining service provider, our engineering team provides DFM (Design for Manufacturability) feedback, helping customers avoid costly design flaws early in the process. Whether you need a functional end-use part, a precision assembly, or a prototype where aesthetics are paramount, our CNC solutions deliver accuracy, repeatability, and speed.

With over 10 years of industry manufacturing experience, Formioo provides high-precision CNC machining services for plastic and metal parts across a wide range of industries, producing over 100,000 CNC parts annually and providing a stable supply to customers worldwide. We work with hundreds of companies across sectors, including automotive, electronics, medical, aerospace, and industrial equipment.

Our CNC Machining Capabilities

Formioo provides a wide range of CNC machining services, including CNC milling, CNC turning, EDM and wire-cut machining, CNC grinding, Swiss machining, and CNC routing. We work with a broad selection of materials such as aluminum, stainless steel, brass, titanium, and engineering plastics to meet the needs of various industries and applications.

We offer a variety of surface treatment options for these processes, such as anodizing, powder coating, sandblasting, polishing, and electroplating. Our machining operations can achieve tolerances as tight as ±0.01 mm, and all parts undergo strict quality inspections using advanced equipment like automated coordinate measuring machines (CMMs) to ensure dimensional accuracy and consistency.

Capabilities for 3, 4, and 5-axis machining to handle both simple and complex geometries.

Equipped with standard and live tooling capabilities for manufacturing cylindrical parts like pins, shafts, and spacers.

Wire and Sinker EDM are non-contact machining techniques designed for precision cutting of deep features.

High-volume CNC machining is the perfect solution for producing large quantities of high-precision parts for mass production applications.

CNC Machining Capabilities

Supported Materials

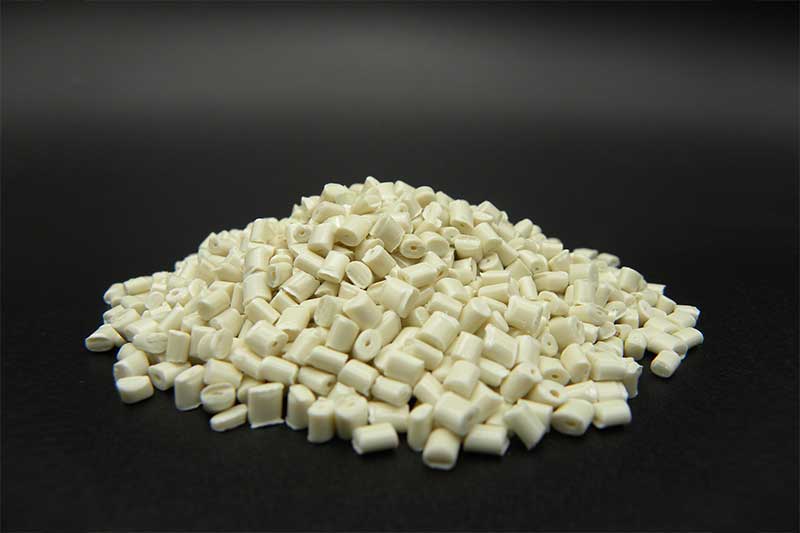

Capable of machining aluminum, stainless steel, brass, copper, carbon steel, and engineering plastics (POM, ABS, Nylon, PEEK, etc.), meeting various industrial and custom production needs.

Machining Accuracy

Standard tolerance controlled within ±0.01mm, ensuring high precision for mechanical components, electronic parts, and industrial applications.

Maximum Machining Size

Maximum machining size up to 1000mm × 600mm × 500mm, suitable for small to medium-sized parts.

Surface Finishing Options

Supports anodizing, polishing, sandblasting, powder coating, electroplating, laser engraving, and more for enhanced durability and aesthetics.

Delivery Time

Standard CNC machining lead time is 5-7 days, with expedited service available for urgent projects.

Massive Network

We work with trusted CNC machining suppliers.

Explore CNC Machining Parts We Manufactured

See our high-quality CNC machining parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Precision Machining Tolerance

| Name | Metals, PEEK, And ULTEM with Drawing | Other Plastics with Drawing | No Drawing |

|---|---|---|---|

| Linear Dimension | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Hole Diameters (Not Reamed) | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

| Shaft Diameters | +/- 0.0025 mm +/- 0.0001 inch | +/- 0.05 mm +/- 0.002 inch | ISO 2768 Medium |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

CNC Machining Materials

Aluminum

Aluminum is a lightweight, high-strength metal widely used in CNC machining for its excellent machinability, corrosion resistance, and thermal conductivity. Its common sizes are 6061, 7075, 5052, and 2024. It is ideal for aerospace, automotive, and electronics applications due to its durability and low density. Aluminum can also be anodized for enhanced surface hardness and aesthetics. Its versatility and cost-effectiveness make it a top choice for precision-engineered components.

• Mill Lead Time: As fast as 3 days

• Finishes: Raw, anodized, bead blasted, polished

Stainless Steel

Stainless steel is a high-strength, corrosion-resistant metal commonly used in CNC machining for its durability and excellent mechanical properties. Its common grades include 304, 316, and 410, each offering varying levels of strength, heat resistance, and anti-corrosion performance. Ideal for medical, aerospace, and industrial applications, stainless steel provides superior wear resistance and can withstand extreme environments. It is also compatible with various surface finishes, including polishing and passivation, to enhance its performance and aesthetics.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, polished, passivated, bead blasted

Carbon Steel & Alloy Steel

Carbon Steel & Alloy Steel are strong, durable metals widely used in CNC machining for their high toughness, wear resistance, and cost-effectiveness. Common grades include 1018, 1045 (carbon steel), and 4140, 4340 (alloy steel), offering varying hardness and machinability. Ideal for automotive, industrial, and structural applications, these steels provide excellent mechanical properties and can be heat-treated for enhanced strength and durability. Various surface treatments, such as black oxide and zinc plating, improve corrosion resistance and appearance.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, black oxide, zinc-plated, powder-coated

Brass & Copper

Brass & Copper are highly machinable metals widely used in CNC machining for their excellent conductivity, corrosion resistance, and aesthetic appeal. Brass (C360, C464) is known for its low friction and antimicrobial properties, making it ideal for fittings, valves, and decorative parts. Copper (C110) offers exceptional electrical and thermal conductivity, making it a top choice for electrical components and heat exchangers. Both materials provide superior durability and can be polished or plated for enhanced performance and appearance.

• Mill Lead Time: As fast as 5 days

• Finishes: Raw, polished, nickel-plated, gold-plated

Titanium

Titanium is a high-strength, lightweight, and corrosion-resistant metal widely used in CNC machining for its exceptional durability and biocompatibility. Common grades include Grade 2 and Grade 5 (Ti-6Al-4V), offering a balance of strength and machinability. Titanium is ideal for aerospace, medical implants, and high-performance automotive parts, where weight reduction and extreme durability are critical. It also withstands high temperatures and harsh environments, making it suitable for demanding applications.

• Mill Lead Time: As fast as 7 days

• Finishes: Raw, bead blasted, polished, anodized

ABS

ABS (Acrylonitrile Butadiene Styrene) is a versatile and cost-effective thermoplastic widely used in CNC machining for its impact resistance, durability, and heat tolerance. Known for its excellent machinability and strength, ABS is a top choice for automotive, consumer electronics, and prototyping applications. It can be easily modified with additives to enhance flame retardancy, UV resistance, or surface hardness, making it adaptable to various industrial needs.

• Mill Lead Time: As fast as 3 days

• Color: Black, neutral matte finish

PC

PC (Polycarbonate) is a high-strength, impact-resistant thermoplastic widely used in CNC machining for its exceptional durability, heat resistance, and optical clarity. Known for its excellent mechanical properties, PC is ideal for automotive, aerospace, and electronic applications, including protective covers and lenses. It offers superior toughness and transparency, making it a great alternative to glass. Additionally, PC can be enhanced with additives for improved UV resistance and flame retardancy, expanding its industrial applications.

• Mill Lead Time: As fast as 3 days

• Colors: Transparent, black, neutral matte finish

POM

POM (Polyoxymethylene, Delrin®) is a high-strength, low-friction thermoplastic widely used in CNC machining for its excellent wear resistance, stiffness, and dimensional stability. Known for its low moisture absorption and high machinability, POM is ideal for gears, bearings, bushings, and mechanical components in automotive, industrial, and consumer applications. It offers good chemical resistance and retains its mechanical properties even in demanding environments, making it a reliable choice for precision parts.

• Mill Lead Time: As fast as 3 days

• Colors: Black, white, neutral matte finish

PMMA

PMMA (Polymethyl Methacrylate, Acrylic) is a transparent, lightweight thermoplastic widely used in CNC machining for its optical clarity, UV resistance, and weather durability. Known for its high impact strength and excellent machinability, PMMA is an ideal choice for display panels, lighting components, lenses, and protective covers. It offers superior scratch resistance compared to polycarbonate and can be polished to achieve a glass-like finish, making it a popular alternative to glass in various applications.

• Mill Lead Time: As fast as 3 days

• Colors: Transparent, black, neutral matte finish

PEEK

PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic widely used in CNC machining for its exceptional strength, heat resistance (up to 260°C), and chemical resistance. Known for its superior mechanical properties, PEEK is ideal for aerospace, medical, and automotive applications, including structural components and high-wear parts. It offers excellent dimensional stability and biocompatibility, making it a top choice for demanding environments where durability and performance are critical.

• Mill Lead Time: As fast as 5 days

• Colors: Natural (beige), black

PTFE

PTFE (Polytetrafluoroethylene, Teflon®) is a high-performance thermoplastic widely used in CNC machining for its exceptional chemical resistance, low friction, and high-temperature tolerance (up to 260°C). Known for its non-stick properties and electrical insulation, PTFE is ideal for seals, gaskets, insulators, and medical components. It maintains stability in extreme environments, making it a preferred material for aerospace, chemical processing, and food-grade applications.

• Mill Lead Time: As fast as 5 days

• Colors: White, black

PEI

PEI (Polyetherimide, Ultem®) is a high-performance thermoplastic widely used in CNC machining for its exceptional heat resistance (up to 217°C), flame retardancy, and mechanical strength. Known for its dimensional stability and excellent electrical insulation, PEI is ideal for aerospace, medical, and electronic applications requiring high-performance materials. It also offers good chemical resistance and maintains strength under extreme conditions, making it a reliable choice for demanding environments.

• Mill Lead Time: As fast as 5 days

• Colors: Amber, black

Nylon

Nylon (Polyamide, PA) is a strong, durable thermoplastic widely used in CNC machining for its high wear resistance, toughness, and chemical stability. Known for its low friction and excellent mechanical properties, Nylon is ideal for gears, bearings, bushings, and structural components in automotive, industrial, and consumer applications. It can absorb moisture, which affects its dimensional stability, but additives can improve its performance for specific uses.

• Mill Lead Time: As fast as 3 days

• Colors: Natural (off-white), black

Finishing Options for CNC Machining

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing with PTFE* |

|

Anodizing | Aluminum | Clear, black, grey, red, blue, gold | Media Blasting, Tumbling, Chem film* |

|

Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

|

Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

|

Electropolishing | Steel, Stainless Steel | — | — |

|

Hand Polishing | Acrylic | — | Enhanced Cosmetic Appearance |

|

Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes, except Electropolish and Powder Coat |

|

Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

|

Passivation | Steel, Stainless Steel | — | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

|

Powder Coating Services | Aluminum, Steel, Stainless Steel | Full Pantone or RAL color catalog | — |

|

Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes, except Electropolish and Powder Coat |

|

Vapor Polishing | CNC Polycarbonate (Clear, Black) | — | Enhanced Cosmetic Appearance, Near Optically Clear Applications |

|

Zinc Plating | Steel, Stainless Steel | Clear (light blue coating). Black (glossy black coating). | Media Blasting, Tumbling, Passivation |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your CNC Machining Supplier Selection Ultimate Guide

Which cnc machining supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo CNC Machining FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What is your standard lead time for CNC machining orders?

Standard lead time is 3-7 days, depending on part complexity and order volume. Expedited options are available.

What types of materials work with your CNC machines?

We provide aluminum, stainless steel, carbon steel, copper, brass, titanium, and plastics like ABS, POM, PC, and Nylon, 45+ certified materials. You can always request a custom material through our custom RFQ process.

Do you offer free samples?

Yes, free swatches and stock samples are free, but the shipping needs to be paid at customers side.

What file format do we use?

All is acceptable, including Ai, tif, jpg, psd, pdf.

What industries do you serve?

We work with aerospace, automotive, medical, electronics, and industrial sectors, delivering high-quality machined parts.

Do you offer DFM (Design for Manufacturability) analysis?

Yes, we provide DFM analysis to help optimize your design, reduce costs, and improve manufacturability.

Can you machine complex parts?

Yes, we specialize in 3-axis, 4-axis, and 5-axis CNC machining, handling intricate designs with high precision.

What tolerances can your CNC machines achieve?

Our standard tolerance is ±0.01 mm, but we can meet tighter tolerances upon request.

How do you safeguard the confidentiality and security of our designs and intellectual property?

At Formioo, we understand the importance of protecting your valuable design IP. That’s why our platform is built with top-tier security and confidentiality at its core. From login to file upload and through to part fulfillment, our secure Digital Manufacturing Ecosystem ensures your intellectual property remains safe and protected at every step of the process.

Is there a minimum order quantity (MOQ) for CNC machining?

We recognize the varying needs of our customers, from single prototypes to large-scale production runs, which is why we do not impose a strict minimum order quantity (MOQ). Whether you need a single machined part or thousands, we are fully equipped to deliver customized solutions tailored to your requirements. Our flexible approach ensures that every client, regardless of order size, receives exceptional service and top-quality results.

How long does it take to receive a part once an order is placed?

The lead time for receiving a CNC machined part from Formioo depends on various factors, such as the complexity of the design, the chosen material, and our current production schedule. CNC machining is renowned for its efficiency, especially for simpler parts, enabling quick turnarounds. In many cases, parts can be delivered as quickly as one week after the machining setup is finalized. For the most accurate estimate tailored to your project, we encourage you to reach out to us for a detailed quote. This ensures we can provide a precise timeframe based on your specific requirements.

CNC Manchining Resource

Are You Looking for CNC Machining Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.