Clean Room Injection Molding Services From China

Formioo offers ISO-certified clean room injection molding services for medical, pharmaceutical, and precision electronics applications. Ensures you receive high-quality, rigorously cleaned medical parts.

- More than 10 years of cleanroom injection molding experience

- High-precision injection molding with tolerance of as low as ±0.01 mm

- 50+ Qualified Materials & 15+ Surface Finishing Types

- 24/7 engineering support

Clean Room Injection Molding Small Batch Production

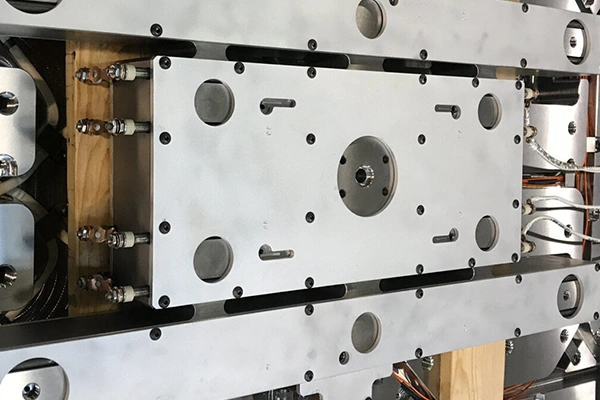

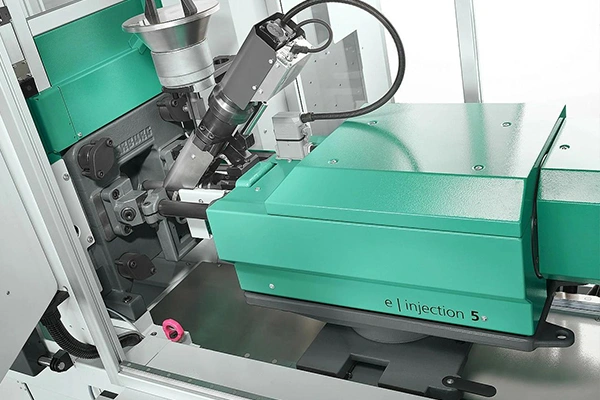

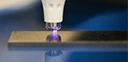

Formioo is a professional clean room injection molding manufacturer in China, specializing in the production of precision plastic parts under ISO class cleanroom environments. Equipped with advanced injection machines, precision molding capabilities, and in-house mold fabrication, we support both prototyping and low-to-mid volume production for highly regulated industries.

We strictly follow GMP and ISO quality standards throughout the entire manufacturing process. From raw material handling to mold validation and part inspection, every step is controlled to ensure contamination-free, high-accuracy production. Our engineering team also provides DFM analysis to help clients optimize their medical or precision components for better manufacturability, safety, and cost-effectiveness.

With over a decade of experience in cleanroom manufacturing, Formioo has delivered millions of plastic parts for applications in medical devices, diagnostic consumables, pharmaceutical packaging, and precision electronics. We help startups and established brands achieve stable, traceable, and certified production from prototype to end use.

Clean Room Injection Molding Services

Formioo offers a comprehensive range of clean room injection molding capabilities to meet the demanding needs of medical, pharmaceutical, and precision electronics industries. Our services include Conventional Clean Room Injection Molding, Hot Runner System Molding, Gas-Assisted Molding, and Micro Injection Molding, all conducted in ISO certified clean room environments. We work with high-purity materials such as medical-grade PP, PE, PC, PEEK, and TPE to ensure biocompatibility, dimensional accuracy, and contamination-free performance.

To enhance product functionality and appearance, we provide a selection of surface finishes, including high-polish, matte texturing, laser etching, and pad printing. With advanced molding equipment and strict in-house quality control, we consistently achieve tolerances of ±0.01 mm or better, depending on material and part geometry. Each part undergoes rigorous inspection and documentation to meet regulatory and client-specific cleanliness standards.

This method applies standard injection molding in a controlled clean environment to minimize contamination and ensure high part consistency.

Utilizing heated channels, it eliminates cold runner residue while ensuring efficient material flow and strict cleanliness during production.

By injecting gas to form hollow sections, it reduces the use of materials and generation of particulate, perfect for contamination-sensitive parts.

For extremely small, high-precision components, it guarantees highest precision and zero contamination for clean room applications.

Clean Room Injection Molding Capabilities

Material Compatibility

We are capable of molding engineering plastics (POM, ABS, Nylon, PEEK, etc.), meeting various industrial and custom production needs.

Printing Accuracy

Our standard tolerance is controlled within ±0.01mm, ensuring high precision for medical, electronic, and industrial applications.

Maximum Build Size

Maximum component size is 1000mm × 600mm × 500mm, best suited for small to mid-sized parts.

Surface Finishing Options

Polishing, sandblasting, powder coating, electroplating, laser engraving, and others are offered for additional protection and cosmetics.

Delivery Time

Typical injection molding lead time is 5-10 days, with rush service available for expedited orders.

Massive Network

We work with trusted injection molding suppliers.

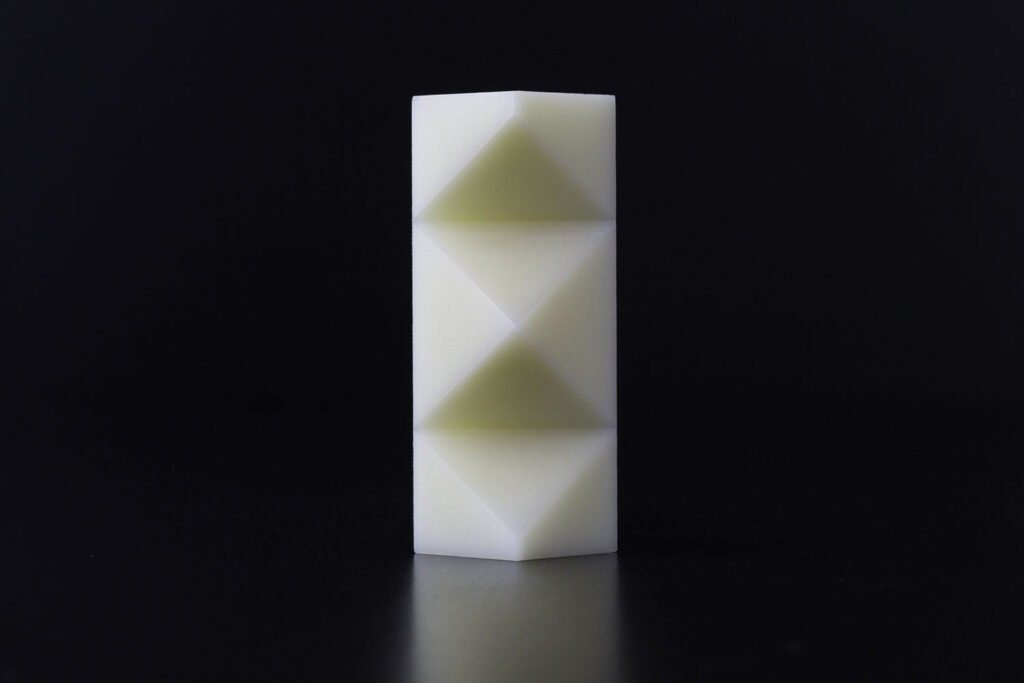

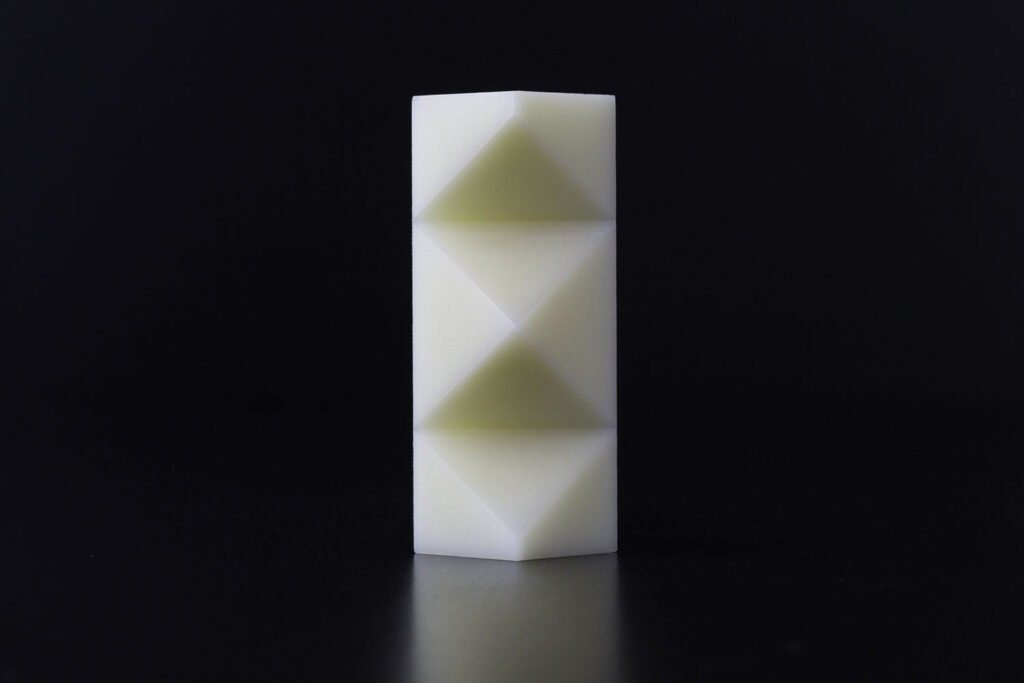

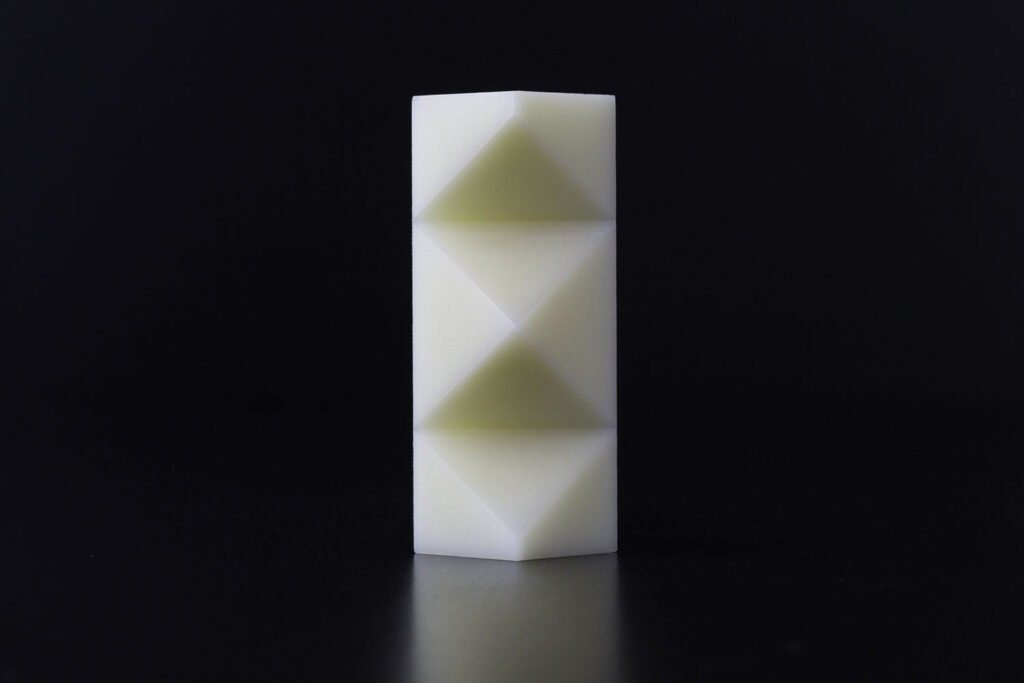

Explore Clean Room Injection Molding Parts We Manufactured

See our high-quality clean room injection molding parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Clean Room Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Clean Room Parts | +/- 0.3 mm to +/- 0.6 mm |

| High-Precision Clean Room Parts | +/- 0.1 mm to +/- 0.3 mm |

| Complex Clean Room Parts | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Clean Room Injection Molding Materials

PP

Polypropylene is used in injection molding of clean rooms because of its low outgassing, good resistance to chemicals, and ease of processing. Its low water absorption holds minimal contamination, a factor that is essential in controlled environments. PP parts are used in fluid devices, enclosures, and medical appliance casings where purity consistency is necessary. For example, laboratory equipment and pharmacy containers are typically produced of PP because of its reliability and strength in sterile environments. Its economic cost and duplicable quality make it an ideal material for clean-environment high-volume precision parts.

- Mill Lead Time: Up to 3 days

- Color: White, natural finish

PE

Polyethylene can be used in injection molding within clean rooms due to its low extractables and chemical inertness. Its smooth surface finish minimizes release of particles to ensure high cleanliness levels. In practice, PE is often used in packaging parts, barrier films, and fluid transfer components in semiconductor and medical device manufacture. For instance, PE tubing and fittings benefit from its non-porous molding behavior and resistance to contaminants, maintaining integrity in valuable clean processes. Its consistent performance in controlled environments and cost-effectiveness also enhance its application in clean room systems.

- Mill Lead Time: Up to 4 days

- Color: Natural, translucent

PS

Polystyrene is very dimensionally stable and exhibits very low water absorption, therefore also well-suited for clean room injection molding. It features a high surface finish minimizing particle formation and providing high cleanliness levels. PS is used widely in the production of precision items such as sensor housings, display units, and medical device casings. Optics and labware, for instance, rely on PS for the maintenance of a contaminant-free environment. Its cost-effectiveness and ease of moldability also enhance its use for high-volume clean room applications where clarity and stability are of great concern.

- Mill Lead Time: Up to 3 days

- Color: Clear, off-white

ABS

ABS enjoys extensive application in clean room injection molding due to its balanced strength, impact resistance, and processability. Its reproducible molding behavior creates parts with tight tolerances and finish surface that reduces particulate contamination. ABS is used in clean room applications for electronic enclosures, control panels, and instrument components. Laboratory instruments and diagnostic equipment, for example, often make use of ABS due to its high strength-to-weight ratio and precision of processing. Its integrity under challenging conditions and stable quality make ABS a highly flexible material in controlled production plants.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PC

Polycarbonate is particularly suited for clean room injection molding because of its high impact strength, high clarity, and good dimensional stability. Its inherent flame resistance and low particle emission make it suited for severe cleanliness applications. PC finds extensive use in electronic enclosures, optical lenses, and accurate instrument parts in clean environments. For example, medical diagnostic instruments and high-precision optical sensors benefit from PC’s resistance to maintaining clarity and integrity even under harsh sterilization. Its strength of performance and reliability make it the favorite choice for most controlled manufacturing processes.

- Mill Lead Time: Up to 4 days

- Color: Transparent, neutral tint

PA

Polyamide or Nylon finds best application in injection molding within the clean room due to its excellent mechanical properties, resistance to wear, and low moisture absorption when surface-treated in the correct manner. Its minimal particulate release during manufacture helps maintain the conditions clean. PA is widely utilized for gears, fittings, and support components in semiconductor and pharmaceutical equipment. High-precision moving parts and structural components in clean room automated equipment, for instance, value the durability and stability of Nylon. Its reliability and predictable operation under rigorous environmental controls render it a suitable engineering plastic for mission-critical clean room applications.

- Mill Lead Time: Up to 5 days

- Color: Natural, off-white

POM

Polyoxymethylene (POM) is highly favored in clean room injection molding because it is dimensionally stable, possesses high stiffness, and possesses low friction. Its smooth surfaces, which are low-particulate, provide contaminant-free conditions. POM is used in real-world applications in precision gears, valves, and medical device parts where tight tolerances and long-term stability are necessary. For example, POM is widely used by clean room fluid control systems and clean room automation because it has wear resistance and stable processing behavior. Its repeatability of performance in high quality demanding situations makes it ideal for mission-critical clean room parts.

- Mill Lead Time: Up to 4 days

- Color: Translucent, natural

PET

Polyester materials such as PET/PBT are used in clean room injection molding because of their superior chemical resistance, dimensional stability, and low absorption of moisture. These characteristics provide molded parts the high levels of clean room environments. They are commonly used for components of medical devices, precision housing, and electronic assembly. Sensor housing and clean fluidic connectors are good examples of the way PET/PBT maintains stability with repeated sterilization cycles. Their high performance and molding constancy make these polyesters a reliable choice for high-quality clean room applications.

- Mill Lead Time: Up to 4 days

- Color: Clear, neutral

PEEK

PEEK is the material of choice in high-performance clean room injection molding due to its superior chemical resistance, heat stability, and ultra-low particulate release. Its intrinsic strength and hardness offer reliable performance under adverse conditions. PEEK is found everywhere in aerospace, medical implants, and semiconductor manufacturing where parts need to be precise after repeated cycles of sterilization. For example, mission-critical parts such as valve assemblies, high-temperature connectors, and structural parts are improved by the wonderful attributes of PEEK. Its stability and reliability in sterile applications render it an ideal high-performance plastic for clean room processing.

- Mill Lead Time: Up to 5 days

- Color: Natural, off-white

PPSU

PPSU is unmatched in clean room injection molding with its excellent thermal stability, chemical resistance, and low extractables. It resists breakage during high-temperature sterilization and is able to have parts contaminant-free. In sanitary room applications, PPSU is typically used in medical device parts, filter housings, and high-precision instrument parts. Fluid handling system parts and diagnostic instrument parts, for instance, take advantage of the stability and transparency of PPSU to meet stringent cleanliness standards. Its proven performance under harsh conditions and consistent processing properties make PPSU a sought-after high-performance product for controlled production facilities.

- Mill Lead Time: Up to 4 days

- Color: Transparent, natural

PPS

PPS is highly appreciated in clean room injection molding due to its excellent chemical resistance, high dimensional stability, and minimal particulate release. Its excellent performance when processed under high temperature makes it ideal to be used where repeated purity and mechanical strength are needed. PPS finds application during the manufacture of electrical connectors, precision pump components, and instrument enclosures within clean environments. For example, semiconductor production lines and medical equipment often integrate PPS parts to benefit from its superior thermal and chemical resistance. Its repeatable processing and enduring performance under sterilization cycles make PPS a strong candidate for clean room applications.

- Mill Lead Time: Up to 4 days

- Color: Gray, neutral finish

PI

Polyimide is an excellent material for clean room injection molding that exhibits excellent high-temperature stability, chemical inertness, and low outgassing. Its low particulate release is ideal for ultra-sensitive uses. PI is utilized extensively in aerospace, medical devices, and high-end electronics where even minute levels of contaminant can compromise functionality. For example, high-precision optical sensors, high-performance connectors, and critical circuit housings in clean environments rely on PI to maintain their integrity under hostile environments. Its robust mechanical properties and excellent performance in sterilized environments make polyimide a top choice for high-end, precision clean room components.

- Mill Lead Time: Up to 5 days

- Color: Amber, neutral finish

Finishing Options for Clean Room Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Plasma Treatment | Plastic, Silicone | — | Plasma Surface Activation |

|

UV Coating | Plastic, Silicone | Clear, Glossy, Matte | UV Curing Process |

|

Polishing | Plastic, Metal | — | Buffing, Tumbling |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Anodizing | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Bead Blasting | Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

|

Laser Etching | Plastic, Metal | — | Laser Machines |

|

Silk Screening | Plastic, Silicone | Multiple | Manual or Automated Process |

|

Vibratory Finishing | Plastic, Metal | — | Vibratory Tumbling |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Clean Room Injection Molding Supplier Selection Ultimate Guide

Which clean room injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Clean Room Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What’s the typical lead time for production?

Our standard lead time is 3–5 working days, subject to the order’s complexity.

Do you have any rapid prototyping facilities?

Yes, we indeed offer a rapid prototyping facility to allow you to refine your design in time.

What are your minimum order levels?

We usually start with 100 units, but we are negotiable based on your needs.

How do you ensure quality in clean room environments?

We follow strict clean room protocols and quality checks to guarantee high precision.

Can you handle custom color or finish requests?

Absolutely, we offer a range of colors and finishes to meet your needs.

Are your materials certified for clean room applications?

Yes, we use certified, low-particulate materials meeting clean room standards.

Clean Room Injection Molding Resource

Are You Looking for Clean Room Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.