Custom Blow Molding Services

Formioo offers flexible blow molding services with low minimum order quantities, fast lead times, and scalable production options.

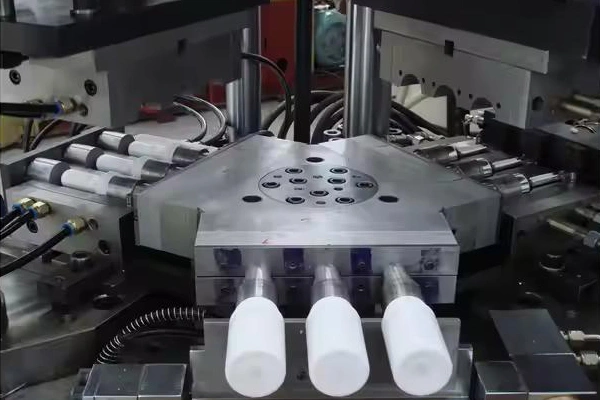

- Multiple shuttle blow molding machines with continuous extrusion capabilities

- Multiple blow molding process support

- Precision Blow Molding with tolerances as tight as ±0.3-0.05 mm

- 50+ Certified Materials & 15+ Surface Finishing Solutions

Blow Molding Small Batch Production Manufacturer from China

Formioo is a custom blow molding services provider for the production of high-quality hollow plastic components. With in-house mold design, rapid tooling capabilities, and fully equipped extrusion, injection, and stretch blow molding lines, we support fast prototyping and agile low-to-medium volume manufacturing to meet tight development timelines.

Our blow molding processes are designed to handle complex geometries, multi-layer structures, and varying wall thicknesses with high consistency. We provide DFM (Design for Manufacturability) feedback and tooling optimization support to help clients avoid common issues like material thinning, flash, and uneven shrinkage. Whether you’re producing bottles, tanks, ducts, or containers, we help ensure structural integrity, clean surfaces, and cost-effective part design.

Since 2016, Formioo has delivered thousands of custom blow molded parts to clients across diverse industries, including automotive, packaging, consumer goods, healthcare, and industrial storage. Our flexible production capacity, low minimum order quantities, and stable lead times allow us to support both startups and established brands in bringing high-quality hollow plastic products to market quickly and cost-effectively.

Our Blow Molding Services

Formioo offers a full range of blow molding services, including extrusion blow molding, injection blow molding, stretch bow molding, and compression blow molding. We support a wide variety of thermoplastics such as HDPE, LDPE, PP, PET, PVC, and PC, allowing us to manufacture hollow parts with different mechanical and chemical performance requirements.

To meet functional and aesthetic needs, we offer surface finishing options such as deflashing, trimming, pad printing, and CNC post-processing. Our blow molding operations typically achieve dimensional tolerances of ±0.3 mm to ±0.5 mm, depending on part geometry and material type. All parts are inspected for wall thickness consistency, sealing quality, and overall dimensional accuracy.

A hot parison is extruded and inflated inside a mold to form uniform, hollow parts.

A preform is injection molded then blown to achieve precise and consistent hollow shapes.

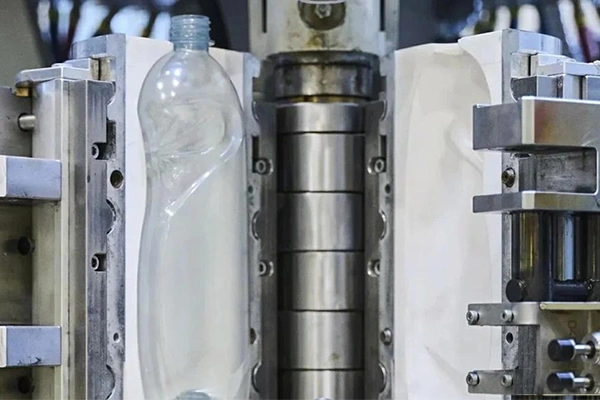

A preheated preform is mechanically stretched before blowing, enhancing clarity and material strength.

Heated plastic is compressed in a mold and then blown to create complex, durable hollow products.

Blow Molding Capabilities

Material Compatibility

We process a wide range of engineering plastics like PET, HDPE, PP, and PVC for a wide range of production needs.

Printing Accuracy

Achieving consistent quality with precision control and minimal variation.

Maximum Build Size

Capable of producing parts up to 1000mm × 600mm × 500mm for small- and medium-sized pieces.

Surface Finishing Options

Offering polishing, painting, and laser engraving capabilities for enhanced aesthetic appearance.

Delivery Time

Average 5-10 day lead time with express options being available.

Massive Network

We work with trusted blow molding suppliers.

Explore Blow Molding Parts We Manufactured

See our high-quality blow molding parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Blow Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Blow Molding Parts | +/- 0.5 mm to +/- 1.0 mm |

| Precision Blow Molding Parts | +/- 0.2 mm to +/- 0.5 mm |

| Complex Blow Molding Parts | +/- 0.3 mm to +/- 0.6 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Blow Molding Materials

HDPE

HDPE is a prime candidate for blow molding due to its high strength-to-density ratio, chemical resistance, and processability. HDPE is lightweight, durable, and recyclable and is well suited for large volume usage. HDPE is used extensively for milk, detergent, and household chemical bottles, industrial drums and pails, and containers. Its impact strength and environmental stress cracking resistance deliver long-term performance in hostile applications.

- Mill Lead Time: Up to 3 days

- Color: White, translucent

PET

PET is most favored in blow molding for its unmatched clarity, light weight, and excellent gas barrier properties. It has extensive use in beverage bottles, packaging of food, and containers due to its freshness retention property and immunity to contamination. PET clarity and stiffness enable it to be used in products like soft drink bottles, water bottles, and salad packs. It is also fully recyclable, making production greener.

- Mill Lead Time: Up to 4 days

- Color: Clear, blue

PP

PP is an intensive blow molding material, described as being resistant to chemicals, elastic, and cost-effective. PP is used in automotive parts, medical bottles, and household products due to its sterility and strength. PP thermal stability enables its use in products like syringes, storage boxes, and food packages. The light weight and lack of fatigue make it applicable in numerous industries.

- Mill Lead Time: Up to 3 days

- Color: White, translucent

PVC

PVC is the most common blow molding process due to its low cost, flexibility, and resistance to chemicals. PVC is employed in its greatest uses in pipes, bottles, and medical tubing, where plasticity and transparency are required. PVC can be customized to possess particular properties, such as plasticity or hardness, and is particularly suited to such products as plumbing fixtures, intravenous bags, and water bottles. Its low processing difficulty and strength ensure consistent performance in different environments.

- Mill Lead Time: Up to 4 days

- Color: Clear, white

PS

PS is an inexpensive but hard plastic with high clarity and can also be blow molded inexpensively. It has widespread use in disposable cups, packages, and containers where its moldability and clarity are advantages. Easy coloration of PS and resistance to moisture are why it finds suitability in uses like yogurt cups, takeaway containers, and packaging trays. Low cost and ease of processing have made it a packaging staple.

- Mill Lead Time: Up to 3 days

- Color: Clear, white

ABS

ABS is a highly impact-resistant blow molding resin possessing mechanical strength and high processability. ABS finds many uses in automotive parts, electrical enclosures, and household appliances due to its stress resistance and dimensional stability. Its paintability or coating with ease and good surface finish have earned ABS the favor of being a favorite material in dashboards, electrical enclosures, and appliance components. Its durability and hardness enable it to provide consistent performance in harsh applications.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PC

PC is a high-impact blow molding grade material that possesses outstanding impact strength, transparency, and heat resistance. PC finds its application in water bottles, baby bottles, and auto components where toughness and clarity are of the utmost importance. PC’s thermal and radiation resistance qualifies it for use in reusable water bottles, as well as medical devices. Its lightness and moldability render it further applicable in other sectors.

- Mill Lead Time: Up to 5 days

- Color: Clear, translucent

EVOH

EVOH is a premium grade blow molding resin that boasts of excellent gas barrier property as well as processability and compatibility with other polymers. It is used widely in multilayered bottles and packaging of food and beverages, where the ability to lock freshness in and prevent contamination is paramount. The excellent transparency and chemical resistance of EVOH are used in applications such as ketchup bottles, condiment bottles, and medical packs. Its co-extrudability with other materials ensures optimum performance for high-demand applications.

- Mill Lead Time: Up to 5 days

- Color: Clear, white

Finishing Options for Blow Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Plastic, PET, PVC | — | Buffing, Tumbling |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

|

UV Coating | Plastic | Glossy, Matte | UV Curing Process |

|

Laser Etching | Plastic, Metal | — | Laser Machines |

|

Powder Coating | Plastic, Metal | Custom Colors | Spray Application |

|

Bead Blasting | Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

Silk Screening | Plastic | Multiple | Manual or Automated Process |

|

Surface Texturing | Plastic, Metal | — | Mold Texturing, Laser Etching |

|

Vibratory Finishing | Plastic, Metal | — | Vibratory Tumbling |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Blow Molding Supplier Selection Ultimate Guide

Which blow molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Blow Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Which plastics do you supply for blow molding?

We handle lots of various plastics like PET, HDPE, PP, and PVC—just inform us what you require, and we’ll obtain the best answer.

What is average lead time?

The majority of projects are completed in 5-10 days, with expedited orders possible if you have a time limit to accommodate.

Can you handle custom designs?

Absolutely. We work with experts who can adapt to your custom needs and bring your concept into existence.

How do you ensure product quality?

We work with suppliers who are ISO-certified and have strict quality checks to ensure that your parts remain reliable.

Do you have a minimum order quantity?

MOQ is project-based, but we always attempt to offer flexible solutions for both large and small volumes.

Are your prices competitive?

We offer competitive pricing that meets the needs of your project. Fill in your information, and we will provide you with a customized quote.

Blow Molding Resource

Are You Looking for Blow Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.