Custom Automotive Prototyping & Manufacturing

At Formioo, we provide rapid prototyping, as well as CNC machining and 3D printing services to our clients in the automotive industry. Accelerate time to market with on-demand production at competitive prices.

- Production-grade products

- Services range from CNC machining to 3D printing.

- Tight tolerances & complex geometries

- Provide design and product verification and performance testing

- 24/7 engineering support

One Stop Solution Provider for Automotive Injection Molding from China

Formioo is a professional injection molding manufacturer in China, specializing in the prototyping and production of custom automotive plastic components. Equipped with advanced injection molding machines, in-house mold manufacturing, and integrated CNC post-processing, we are capable of producing complex, tight-tolerance parts that meet both structural and cosmetic requirements in automotive applications.

Our injection molding services are built to solve key challenges in automotive development, from early-stage prototype iteration to low-volume pre-production and high-volume manufacturing. We help clients reduce tooling costs, shorten lead times, and improve design performance through DFM support, mold flow simulation, and material recommendations. Whether it’s thin-wall parts, undercuts, or high-heat resistant components, we provide the expertise to bring your design to life—accurately and efficiently.

Backed by 10+ years of hands-on manufacturing experience, Formioo delivers hundreds of thousands of molded parts annually for interior systems, lighting assemblies, connectors, housings, and functional under-the-hood components. Our clients include OEMs, Tier 1 suppliers, and innovative automotive startups who rely on us for scalable, fast-turn injection molding solutions.

What kinds of automotive injection molding parts can we manufacture?

Formioo manufactures a wide range of injection molded plastic parts for the automotive industry, including interior trim panels, dashboard components, HVAC ducts, lighting housings, clips and fasteners, connectors, fluid reservoirs, and under-the-hood covers. We work with a variety of automotive-grade thermoplastics such as ABS, PP, PC/ABS, PA6/PA66, PBT, and high-performance materials like PPS and PEEK to meet requirements for heat resistance, impact strength, dimensional stability, and long-term durability.

To ensure both functional and cosmetic performance, we support secondary operations and value-added technologies such as insert molding, overmolding, ultrasonic welding, and multi-cavity tooling. We also offer a full suite of surface finishing options, including texturing, laser marking, painting, and chrome plating. Our molding processes maintain tight tolerances and high repeatability, backed by rigorous quality control procedures including CMM inspection and in-process monitoring, ensuring every part meets the exacting standards of modern automotive production.

- Bumpers

- grilles

- mirror

- Air Conditioning Systems

- Lighting System

- Night Vision Device

- Helmets

- Tank Model

- Engines

- Fastening Items such as Screws

- Electrical Parts

- Vacuum Pumps

- Sensor covers

- switch panels

- control module enclosures

Automotive Injection Molding Capabilities

Material Compatibility

We process wide ranges of engineering plastics, including PP, ABS, PC, Nylon, POM, PBT, and reinforced composites, for strength, heat resistance, and durability.

Printing Accuracy

We maintain our standard tolerances at ±0.05mm, which provides accuracy for critical automotive components.

Maximum Build Size

We offer mass molding with the maximum size of an individual part being 1500mm × 1000mm × 500mm appropriate for the automotive industry.

Surface Finishing Options

We offer texturing, painting, electroplating, chrome coating, laser engraving, and pad printing to enhance aesthetics and performance.

Delivery Time

Our standard injection molding lead time is 10-20 days, with expedited services available for urgent projects.

Massive Network

We worked with trusted injection molding suppliers.

This is Modal Title

[contact-form-7 id="852" title="Contact Us"]

Explore Our Latest Automotive Injection Molding Products

Discover our precision-engineered automotive parts and see the quality for yourself. From prototyping to mass production, our high-performance components meet the toughest industry standards.

Automotive Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Automotive Parts | +/- 0.2 mm to +/- 0.5 mm |

| Precision Automotive Parts | +/- 0.05 mm to +/- 0.2 mm |

| Complex Automotive Parts | +/- 0.3 mm to +/- 0.8 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

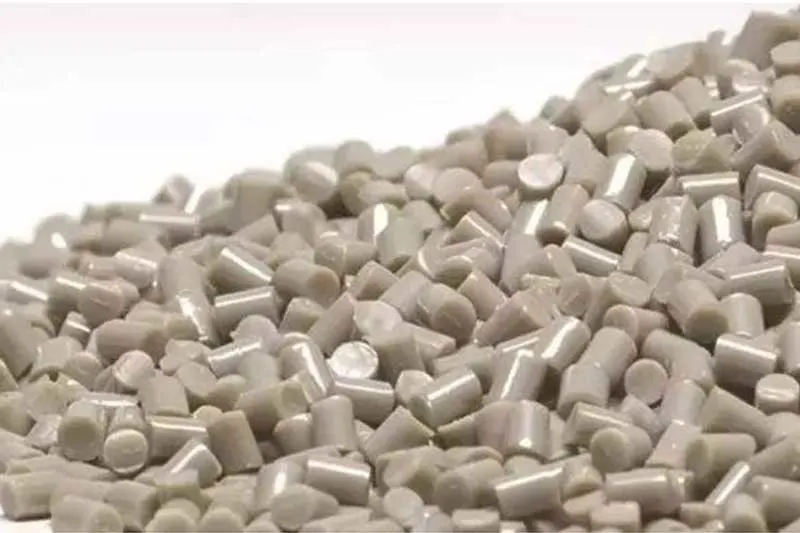

Automotive Injection Molding Materials

PP

PP is a lightweight, chemical-resistant material well suited for automotive injection molding. It gets into bumpers, interior trim, and storage compartments due to its economy and durability. PP’s flexibility and fatigue resistance make it good for repeated-stress uses such as clips, hinges, and fluid containers. Its chemical and moisture resistance ensure reliable performance in under-the-hood uses.

- Mill Lead Time: 5-7 days

- Color: Natural, black, gray, and custom colors available

PE

PE is valued in automotive injection molding for its resistance to chemicals and low cost. PE is utilized regularly in fuel tanks, fluid reservoirs, and under-hood components where oil and chemical resistance are necessary. PE’s light weight contributes to improved fuel economy, and its strength ensures long-term performance in extreme conditions. Its moldability leads it to suit large and complex parts.

- Mill Lead Time: 5-7 days

- Color: Natural, black, and custom colors available

ABS

ABS (Acrylonitrile Butadiene Styrene) is a common emulsion-made thermoplastic polymer that is widely used in automotive parts, toys, and electronic enclosures due to its good resistance to corrosive chemicals.

ABS is easy to machine and possesses a relatively lower melting point, which is easy to mold and form. It possesses high impact resistance that makes it ideal for applications exposed to extreme stress or pressure. Because of such unique characteristics, ABS has emerged as a popular material among various industries around the world.

Common applications: Enclosures

PC

PC is noted for its high impact strength and transparency and hence is used in automotive lighting components like headlight covers and instrument panels. Its strength and thermal resistance also make it suitable for exterior components exposed to harsh weather. PC’s maintenance of integrity and transparency under stress makes it safe to operate in safety-critical applications.

- Mill Lead Time: 7-10 days

- Color: Transparent, black, white, and custom colors available

PA

PA has high strength, wear resistance, and heat stability and hence is employed in under-the-hood components like engine covers, gears, and bearings. Its high-temperature resistance and mechanical stress ability ensure reliable performance under hostile automotive application. PA’s low friction coefficient gives it applicability to moving parts, while resistance to chemicals enhances life.

- Mill Lead Time: 7-10 days

- Color: Natural, black, white, and custom colors available

POM

POM finds wide use in automotive injection molding for its toughness and low friction. It is suitable for functional elements like clips, fasteners, and gears where the requirement is for strength and precision. The ability of POM to resist chemical and physical wear means that it lasts longer, even under extreme conditions. Its dimensional stability also renders it suitable for precision parts.

- Mill Lead Time: 7-10 days

- Color: Natural, black, white, and custom colors available

PBT

PBT (Polybutylene Terephthalate) is a high-performance thermoplastic material that exhibits good dimensional stability, heat resistance, and electrical insulation, making it suitable for Automotive Injection Molding. It is chemical- and moisture-resistant and suitable for under-the-hood uses, connectors, and sensor housings. Its potential for high-volume production through rapid crystallization offers effective production of long-lasting, accurate automotive parts.

- Mill Lead Time: As fast as 7 days

- Color: Black, Gray, Natural, Custom Colors Available

PEEK

PEEK is a polymer of engineering used in automotive injection molding for its excellent heat and chemical resistance. PEEK is ideal for engine components, sensor caps, and other parts that endure high temperature and corrosive environments. PEEK’s strength and toughness deliver repetitive performance in the most rigorous car applications.

- Mill Lead Time: 10-14 days

- Color: Natural, black, and custom colors available

PPS

PPS is most suitable for automotive injection moldings due to its good thermal and chemical resistance. It is also discovered to be extensively applied in engine components, sensor encapsulation, and electrical connectors where durability and reliability are the most important factors. Its resistance to the environment enables long-term performance in highly stressful applications.

- Mill Lead Time: 10-14 days

- Color: Natural, black, and custom colors available

LCP

LCP exhibits superior heat resistance and low warping and hence used in various precision automotive components like electronic connectors and sensor housing. Dimensional stability under elevated temperatures ensures functionality. Chemical and wear resistance of LCP are the key reasons why the material can function under challenging conditions.

- Mill Lead Time: 10-14 days

- Color: Natural, black, and custom colors available

Finishing Options for Automotive Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Painting | ABS, PP, PC, PA, POM | Any custom color | Primer coating, UV coating, texture finishing |

|

Texture Finishing | ABS, PP, PC, PA, POM | Depends on base material | Painting, laser engraving, polishing |

|

Polishing | ABS, PC, PP, PA | Glossy finish (clear or colored) | Painting, texture finishing |

|

Electroplating | ABS, PC/ABS | Chrome, nickel, gold, silver | Primer coating, polishing |

|

Anodizing | Aluminum-filled plastics | Clear, black, gold, custom colors | Media blasting, chemical film |

|

Laser Engraving | ABS, PC, PP, PA, POM | Black, gray, or material-dependent | Texture finishing, polishing |

|

Sandblasting | ABS, PC, PP, PA, POM | Matte finish (material color) | Painting, texture finishing |

|

UV Coating | ABS, PC, PP | Clear or custom colors | Painting, texture finishing |

|

Powder Coating | Metal-filled plastics | Any custom color | Media blasting, chemical film |

|

Hot Stamping | ABS, PP, PC, PA | Gold, silver, metallic colors | Texture finishing, polishing |

|

Vapor Depostion | ABS, PC, PP | Chrome, metallic finishes | Polishing, texture finishing |

|

Soft-Touch Coating | ABS, PP, PC | Black, gray, custom colors | Texture finishing, UV coating |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Automotive Injection Molding Supplier Selection Ultimate Guide

Which automotive injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials.Download our lasted supplier guide.

Formioo Automotive Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What kinds of car parts can you produce by injection molding?

Our partner suppliers supply a variety of parts including bumpers, dashboards, door panels, light housings, and under-hood parts like clips and brackets. They sell interior and exterior car parts.

What kinds of materials do you process for automotive injection molding?

We do have experience working with plastics like ABS, PP, PC, PA (Nylon), POM, as well as high-performance plastics like PEEK and PPS. They are all chosen by strength, durability, and requirements for application.

Do you prototype and mass-produce?

Yes, we prototype and mass-produce. Our facility offers fast prototyping for testing and scalable production for bulk quantities.

What is your typical lead time for car injection molding?

Your prototyping lead times would be 5-10 days, and for mass production, 10-15 days. We offer rush programs for short notice orders.

What tolerances are you able to hold in automotive injection molding?

Our collaborating manufacturers achieve tight tolerances of ±0.05 mm with precision for critical automotive parts.

Are your automotive parts industry standard?

Yes, our ISO certified manufacturers qualify all parts to international safety and quality standards.

Automotive Injection Molding Resource

Are You Looking forAutomotive Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.