Custom Aluminum Extrusion Molding Services

Formioo offers custom aluminium extrusion services for profiles, housings and structural components with an accuracy of ±0.1 mm. Delivery within 7 days.

- More than ten years of professional experience in aluminum extrusion molding

- Wide variety of aluminum alloys to address various industry needs

- Affordable solutions both for low-volume manufacturing and bulk manufacturing

- Customized to your specific shape, specifications and application needs

Reliable Aluminum Extrusion Molding Manufacturer from China

Formioo is a custom aluminum extrusion molding services provider for structural and precision aluminum parts. With in-house die design, rapid tooling, and precision extrusion lines, we support fast prototyping and short production lead times, helping clients accelerate development cycles without compromising accuracy or quality.

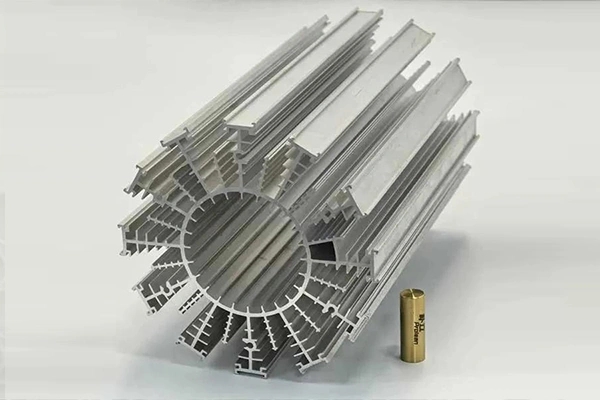

Our extrusion services are optimized for complex aluminum profiles with tight cross-sectional tolerances. We provide DFM (Design for Manufacturability) feedback to minimize die complexity, improve material flow, and enhance part consistency. Whether you’re dealing with lightweight structural components, enclosures, or high-precision channels, our team helps resolve challenges like wall thickness variation, distortion, and alignment issues during post-processing or assembly.

With over 10 years of manufacturing experience, Formioo delivers thousands of aluminum-extruded parts every month to clients in automotive, construction, lighting, electronics, and industrial machinery sectors. Our ability to support both low-volume and mid-scale production runs makes us a flexible and reliable partner for manufacturers seeking high-quality aluminum profiles at competitive lead times.

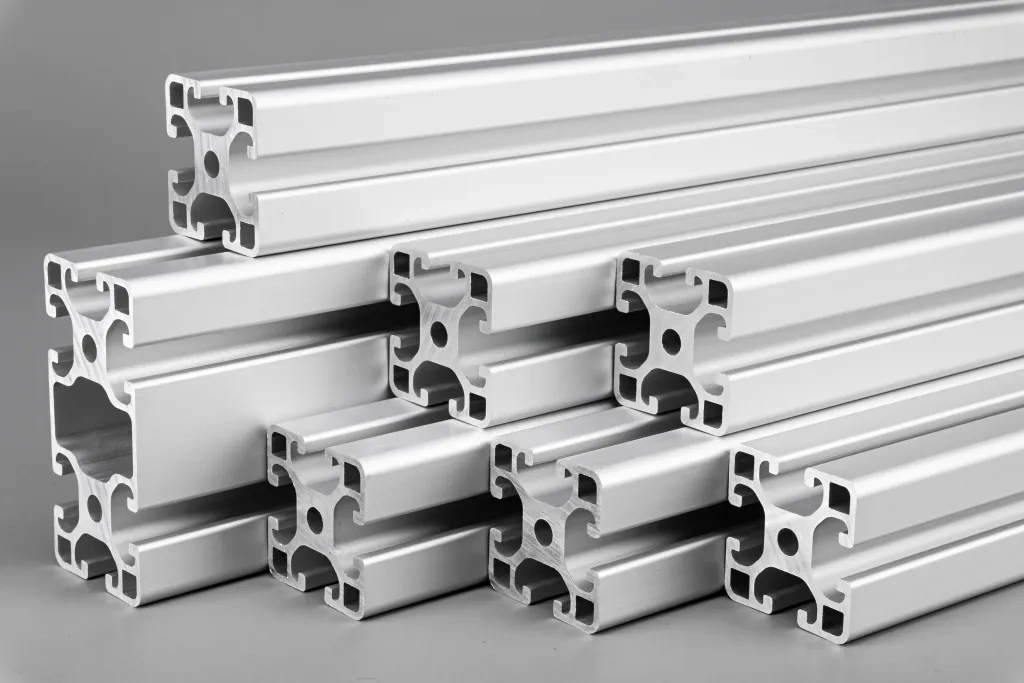

Our Aluminum Extrusion Molding Services

Formioo offers a complete range of aluminum extrusion molding services, including Standard Extrusion for simple solid shapes, Hollow Extrusion for lightweight structural profiles, Seamless Tube Extrusion for high-pressure or aesthetic applications, and Complex Profile Extrusion for intricate cross-sectional geometries. We work with a wide selection of aluminum alloys, such as 6061, 6063, 6082, and 7075, to meet different requirements for strength, corrosion resistance, and surface finish across various industries.

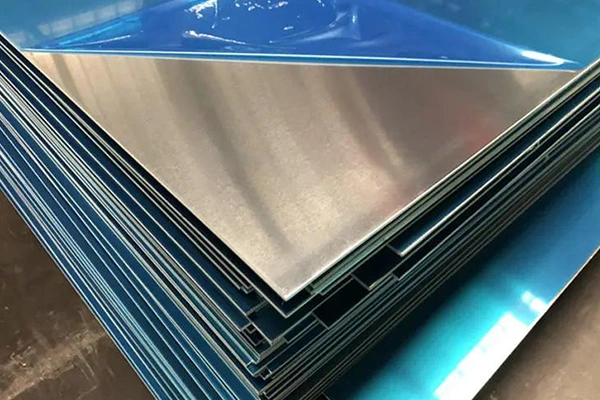

We offer a range of surface finishing options for aluminum extruded parts, including anodizing, powder coating, sandblasting, brushing, and polishing. Our extrusion process maintains consistent profile quality and achieves standard tolerances of ±0.15 mm, with precision profiles reaching up to ±0.1 mm depending on geometry and material specifications. All parts undergo dimensional checks to ensure stability and repeatability across production runs.

Produces solid aluminum profiles for versatile industrial and construction applications.

Creates lightweight, durable tubular shapes for structural and mechanical uses.

Manufactures precision seamless aluminum tubes for high-performance industries.

Delivers intricate, multi-dimensional profiles for specialized and advanced applications.

Aluminum Extrusion Molding Capabilities

Material Compatibility

We extrude from a range of aluminum alloys, including 6061, 6063, 5052, and more, designed to meet different industrial and custom production needs.

Printing Accuracy

We offer high-precision extrusion with tight tolerances to meet consistent quality demands for critical uses.

Maximum Build Size

We have the ability to accommodate lengths of extrusion up to 2000mm to cater to projects of varying sizes and complexity.

Surface Finishing Options

We offer anodizing, polishing, powder coating, and other surface finishes to enhance strength and appearance.

Delivery Time

Our standard turnaround is 7-14 days, and our express services are offered for those urgent projects.

Massive Network

We work with trusted aluminum extrusion molding suppliers.

Explore Aluminum Extrusion Molding Parts We Manufactured

See our high-quality aluminum extrusion molding parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Aluminum Extrusion Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Aluminum Extrusion Parts | +/- 0.5 mm to +/- 1.0 mm |

| Precision Aluminum Extrusion Parts | +/- 0.2 mm to +/- 0.5 mm |

| Complex Aluminum Extrusion Parts | +/- 0.3 mm to +/- 0.8 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

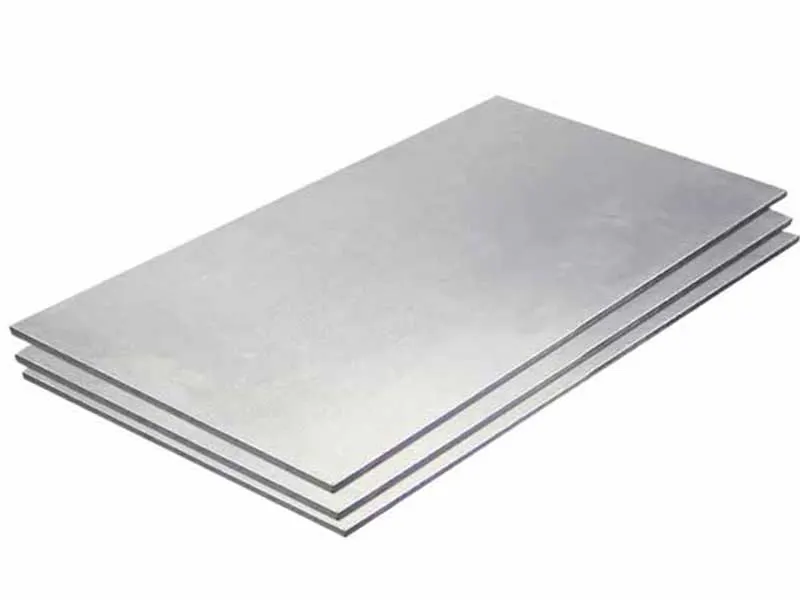

Aluminum Extrusion Molding Materials

Aluminum Alloy 6063

6063 Aluminum Alloy is very suited to Aluminum Extrusion Molding due to its improved extrudability and fine surface finish. It has wide usage in building structures, such as window profiles, door profiles, and ornamental railings. For example, the anodizing ease and visual appeal of 6063 extrusions are often used in new building façades, curtain walls, and light structural elements. Its balanced strength and formability enable the development of intricate profiles and decorative motifs. The consistent quality of the material allows for dependability in domestic houses and business buildings.

- Mill Lead Time: Approximately 5 days

- Finishes: Anodized, powder coated, raw, bead blasted

Aluminum Alloy 6061

Aluminum Alloy 6061 is one of the finest ones to use for Aluminum Extrusion Molding as it has very high versatility, good welding properties, and corrosion resistance.Parts of automobiles, aerospace components, and marine hardware are just some of its applications. Bicycle frames, aircraft structural components, and boat railings, for example, utilize the strength of the alloy in bringing dynamic loads while ensuring ease of machining. Its heat-treatability property also enhances mechanical performance and makes it appropriate for various complex designs and accuracy-relation applications in consumer as well as industrial goods.

- Mill Lead Time: Approximately 7 days

- Finishes: T6 temper, anodized, brushed, raw

Aluminum Alloy 6005

Aluminum Alloy 6005 is produced for high extrudability and is significantly applied in Aluminum Extrusion Molding. Its high grain structure and proportional strength allow it to form complex profiles with high dimensional precision. It has extremely common application in architectural trims, window frames, and even sports equipment. For example, 6005 extrusions are used in the parts of bicycles, ladder rails, and industrial framing systems based on their stable performance and reliable surface finish. Its excellent machining properties also provide customizability in various fabrication procedures.

- Mill Lead Time: Approximately 6 days

- Finishes: Brushed, anodized, raw, painted

Aluminum Alloy 6082

Aluminum Alloy 6082 is highly appropriate for Aluminum Extrusion Molding because it has higher strength and good weldability using flux as well as excellent corrosion resistance. The alloy is primarily used for load-bearing structures possessing excellent durability and load-carrying ability. It is widely applied in the construction, transport, and machinery industries. It finds application in powder-coatable heavy-duty window frames, structural beam components, and car chassis components, for instance, due to its impact resistance and its accuracy in extrusion. Its compatibility with downstream processing technologies like powder coating and anodizing also enhances its application in high-performance engineering.

- Mill Lead Time: Approximately 8 days

- Finishes: Anodized, powder coated, raw, brushed

Aluminum Alloy 6060

Aluminum Alloy 6060 possesses very good consistency and has a bright finish, thereby making it extremely suitable for Aluminum Extrusion Molding. Its enhanced formability allows complex profiles to be manufactured, while its strength is appropriate both for structure as well as for ornamentation. The alloy is extensively employed for the manufacture of door frames, window sills, and other architectural elements. For example, interior design components of today and business storefronts utilize 6060 because of its attractive look in addition to its consistent performance. Its cross-processing and finishing versatility also evoke its value in diversified industries.

- Mill Lead Time: Approximately 5 days

- Finishes: Brushed, anodized, raw, bead blasted

Aluminum Alloy 6101

Aluminum Alloy 6101 is specially intended for superior electrical conductivity and superior mechanical strength, hence a preferred one for specialty Aluminum Extrusion Molding. Its consistent quality and longer life make it a reliable product for the production of bus bars, electric components, and power distribution components. Electrical infrastructure cabinets and manufacturing equipment components, for example, frequently use 6101 extrusions to deliver consistent performance when loaded with high electrical pressures. Its compatibility with many treatments such as anodizing and powder coating enables it to be employed in appearance or functional applications in energy and infrastructure sectors.

- Mill Lead Time: Approximately 7 days

- Finishes: Anodized, powder coated, raw, polished

Finishing Options for Aluminum Extrusion Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Anodizing | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Powder Coating | Aluminum | Custom Colors | Spray Application |

|

Surface Texturing | Aluminum | — | Mold Texturing, Laser Etching |

|

Polishing | Aluminum | — | Buffing, Tumbling |

|

Electroplating | Aluminum, Steel | Chrome, Gold, Silver | Electroplating Bath |

|

Painting | Aluminum | Custom Colors | Spray, Dip, or Brush Application |

|

Bead Blasting | Aluminum | — | Sandblasting, Abrasive Blasting |

|

Laser Etching | Aluminum | — | Laser Machines |

|

UV Coating | Aluminum | Glossy, Matte | UV Curing Process |

|

Chem Film | Aluminum | Clear, Gold | Media Blasting, Tumbling, Anodizing |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Aluminum Extrusion Molding Supplier Selection Ultimate Guide

Which aluminum extrusion molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo Aluminum Extrusion Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Can you handle custom extrusion profiles?

Yes, we do custom profiles and complex shapes, so you receive the perfect design for your application.

How do you assure quality in aluminum extrusion?

We possess the best quality control machinery and test our products extensively, so you receive uniform, high-quality material each time.

What's your extrusion project lead time?

Our standard lead time is 4-6 weeks, but we can expedite jobs to accommodate same-day orders to get you on your tight deadline.

Do you provide design assistance?

Yes, our engineering team can make your design manufacturable to save you money and time.

Do you have any hollow or multi-cavity profile extrusion?

Yes, free swatches and stock samples are free, but the shipping needs to be paid at customers side.

What is your minimum order quantity (MOQ)?

We have a fluctuating MOQ that both enables us to accommodate small runs as well as huge runs to meet your needs.

Aluminum Extrusion Molding Resource

Are You Looking for Aluminum Extrusion Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.