Custom Aluminium Die Casting Services

Formioo provides high-precision aluminum die casting services for complex metal parts, enabling the production of one-off prototypes or over 1,000 production parts in aluminum.

- More than 10 years experience of aluminium die casting

- Precise die casting with consistent quality and tight tolerances

- Wide range of aluminum alloys to cater to many industrial uses

- Experienced and knowledgeable engineers

Reliable Aluminium Die Casting Manufacturer from China

Formioo is a custom aluminium die casting services provider for precision metal parts with complex geometries. Equipped with dedicated mold design teams and high-efficiency die casting lines, we enable quick design validation and reliable part production with reduced lead times.

Our aluminium die casting process ensures high dimensional accuracy, excellent surface finish, and repeatable results across both simple and intricate parts. We provide DFM (Design for Manufacturability) support to address potential issues like shrinkage, porosity, and draft angle optimization—reducing production risks and improving tooling efficiency. Whether you’re developing thin-walled enclosures, structural housings, or detailed heat-dissipating parts, our team delivers solutions that balance performance, weight, and cost.

Since 2016, Formioo has delivered thousands of custom aluminium die-cast components to clients across the automotive, aerospace, consumer electronics, lighting, and industrial machinery sectors. Our flexible production setup supports both low-volume trial runs and medium-scale batch manufacturing, making us a dependable partner for companies seeking high-quality, precision-cast parts with stable lead times and competitive pricing.

Our Aluminium Die Casting Services

Formioo offers a full range of aluminium die casting technologies to meet diverse production needs, including high-pressure die casting, low-pressure die casting, gravity die casting, and squeeze casting. We support multiple aluminium alloys such as A380, ADC12, 6061, and 7075 to accommodate various strength, thermal conductivity, and machinability requirements.

To enhance both functionality and appearance, we offer a wide selection of surface treatments for aluminium castings, including shot blasting, anodizing, powder coating, chromate conversion, polishing, and CNC post-machining. Depending on the casting method and part geometry, we typically achieve dimensional tolerances of ±0.10 mm to ±0.20 mm. All castings are inspected for dimensional accuracy, surface finish, and structural integrity to ensure reliable performance from prototype to production.

High-speed process for complex, thin-walled aluminum parts.

Ideal for producing dense, high-integrity aluminum components.

Low-cost, simple process for medium-volume aluminum parts.

Combines casting and forging for superior strength and precision.

Aluminium Die Casting Capabilities

Material Compatibility

We manufacture a wide range of aluminum alloys, including ADC12, A380, A360, and more, to cater to diverse industrial and special production needs.

Printing Accuracy

We deliver high-precision die casting with tight tolerances, ensuring consistent quality for demanding applications.

Maximum Build Size

We support die casting for parts up to 1000mm × 600mm × 500mm, accommodating projects of various sizes and complexities.

Surface Finishing Options

We offer polishing, powder coating, anodizing, and other coatings to enhance strength and appearance.

Delivery Time

We maintain a normal lead time of 7-14 days, with express options to accommodate urgent works.

Massive Network

We work with trusted aluminium die casting suppliers.

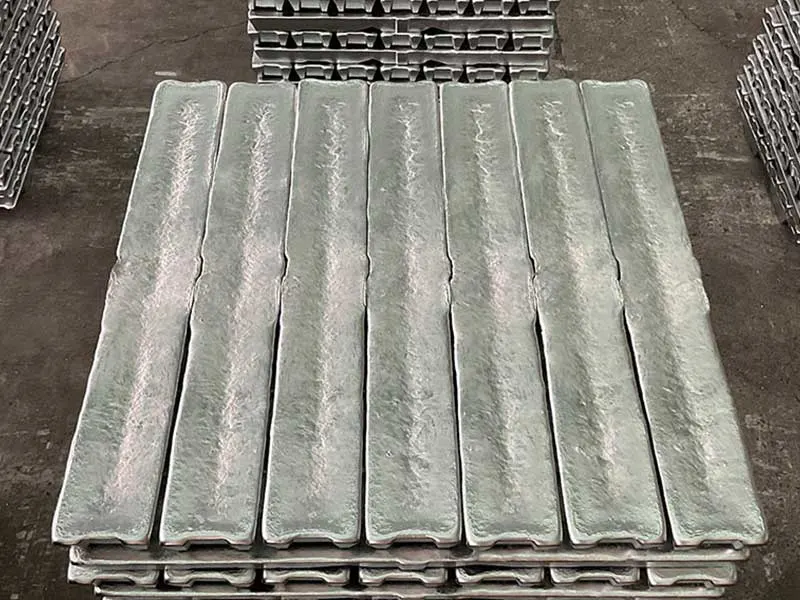

Explore Aluminium Die Casting Parts We Manufactured

See our high-quality aluminium die casting parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Aluminium Die Casting Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Aluminum Die Casting Parts | +/- 0.5 mm to +/- 1.0 mm |

| Precision Aluminum Die Casting Parts | +/- 0.2 mm to +/- 0.5 mm |

| Complex Aluminum Die Casting Parts | +/- 0.3 mm to +/- 0.6 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

Aluminium Die Casting Materials

ADC12

ADC12 is an excellent aluminium die casting alloy with high fluidity, low porosity, and superior dimensional stability. It offers superior corrosion resistance and is ideally suited to producing intricate, detailed components. In actual application, ADC12 is widely used in auto parts such as engine compartments, transmission cases, dashboards, and radiator supports. It is also found in home appliances, electronic boxes, and consumer goods where precision and reliability are crucial. Its ease of mass production gives it a favored position among manufacturers.

- Mill Lead Time: Typically 5-7 days

- Finishes: Raw, painted, anodized, polished

A380

A380 is a tough and versatile aluminium alloy best suited for die casting because of its moderate strength, excellent fluidity, and castability. It offers a good surface finish and also has stability for the casting of complex components. A380 is extensively utilized in automotive engine blocks, gearbox cases, pump cases, and trim components. It can be mass-produced with no loss of quality because of its heat resistance and excellent machining characteristics. A380 is used by manufacturers because of its efficiency and reliable performance in a broad variety of challenging applications.

- Mill Lead Time: Around 4-6 days

- Finishes: Machined, polished, painted, anodized

A356

A356 possesses a high strength-to-weight ratio with very good casting properties, so the alloy is an ideal material to be used in precision castings of aluminium die casting. Its good thermal conductivity and castability make it an ideal metal while producing car suspension components, cylinder heads, and other structural parts. The alloy retains stable performance under temperature variations, and this is very crucial in high-performance engine components and also aerospace applications. Its strength and accuracy verified, A356 has established a secure position in applications where performance consistency and quality are of prime importance.

- Mill Lead Time: Approximately 7-10 days

- Finishes: Heat-treated, machined, anodized, powder-coated

A413

A413 is highly valued for enhanced mechanical properties and enhanced cast behavior. It possesses better dimensional stability and fluidity and a simplicity to mold intricate shapes. General uses include motor vehicle lighting housings, gearbox components, and general electrical connectors. The alloy’s balanced performance enables inexpensive manufacturing at high quality. Its dependability and ease of use have been broadly applied across various industries and speak well to its position within trusted, high-precision manufacturing methods.

- Mill Lead Time: Estimated 6-8 days

- Finishes: Raw, machined, painted, polished

A360

A360 meets satisfactory fluidity, satisfactory mechanical properties, and satisfactory corrosion resistance, and hence it is a very appropriate material to be used in die casting of aluminium. It is applied widely in the electrical and automobile sectors, where the need for complex forms and high accuracy dimensions is of paramount consideration. For example, A360 is used to manufacture transmission cases, instrument panels, and industrial fittings. Its machinability and good performance make it possible for producers to reach good quality and productivity. Good heat dissipation and weight loss give the alloy high desirability overall.

- Mill Lead Time: Typically 5-7 days

- Finishes: Raw, anodized, painted, polished

Finishing Options for Aluminium Die Casting

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Anodizing (Type II & III) | Aluminum | Clear, Black, Gold | Media Blasting, Tumbling, Coating |

|

Powder Coating | Aluminum | Custom Colors | Spray Application |

|

Polishing | Aluminum | — | Buffing, Tumbling |

|

Electroplating | Aluminum, Steel | Chrome, Gold, Silver | Electroplating Bath |

|

Painting | Aluminum | Custom Colors | Spray, Dip, or Brush Application |

|

Bead Blasting | Aluminum | — | Sandblasting, Abrasive Blasting |

|

Laser Etching | Aluminum | — | Laser Machines |

|

UV Coating | Aluminum | Glossy, Matte | UV Curing Process |

|

Chem Film | Aluminum | Clear, Gold | Media Blasting, Tumbling, Anodizing |

|

Surface Texturing | Aluminum | — | Mold Texturing, Laser Etching |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Aluminium Die Casting Supplier Selection Ultimate Guide

Which aluminium die casting supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials .Download our lasted supplier guide.

Formioo Aluminium Die Casting FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

Which aluminum alloys you use in die casting?

We use commonly used alloys like A380, A383, and ADC12, hence giving you the right strength-to-performance ratio.

Can you handle high-volume production?

Absolutely! We specialize in high-volume die casting, therefore you can meet bulk orders with ease.

What is your minimum order quantity (MOQ)?

Our MOQ is negotiable, and we accept small as well as large orders to fit your needs.

Do you offer surface finishing options?

Yes, we provide powder coating, anodizing, polishing, and others so that your components appear and perform just right.

How do you maintain quality in die casting?

We possess advanced quality control systems and undertake rigorous testing, so you receive consistent good-quality parts.

What is your die casting project lead time?

Our standard lead time is 6-8 weeks, but for rush orders, we can finish sooner so that you are not held up.

Aluminium Die Casting Resource

Are You Looking for Aluminium Die Casting Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.