Manufacturing on Demand for the Aerospace Industry

Formioo delivers high-quality, on-demand manufacturing services for your custom aerospace prototypes and production parts. The fastest mold guarantee in 10 days.

- Instant quot & free DFM

- Aerospace-grade materials like high-end thermoplastics PEEK, Ultem, and PPS

- More than ten years of experience in manufacturing aerospace parts

- Wide range of services, from CNC to 3D printing

- 24/7 engineering support

One Stop Solution Provider for Aerospace Manufacturing and Prototyping from China

Formioo is a professional injection molding manufacturer in China, offering high-precision prototyping services for aerospace components made from plastic and metal. Our factory is equipped with advanced injection molding machines, in-house CNC machining centers, and rapid tooling systems, enabling us to produce complex, tight-tolerance parts for both visual and functional validation at speed.

Our aerospace prototyping service is designed to support fast iteration, risk reduction, and design verification under strict aerospace requirements. We assist customers in solving early-stage challenges such as material selection, wall thickness optimization, and moldability issues. Whether you need lightweight structural parts, flame-retardant housings, or aerodynamic surface models, we help streamline your development process and reduce time-to-certification.

Since 2016, Formioo has delivered thousands of prototypes for aerospace applications, including cabin interiors, ventilation ducts, brackets, and housings. We serve OEMs, Tier 1 suppliers, and R&D teams with low-volume, high-precision part production, backed by consistent quality, responsive support, and on-time delivery.

What kind of aerospace & defense parts can we make?

Formioo specializes in producing precision injection molded components for aerospace and defense applications, including lightweight housings, cable connectors, ducting elements, bracket covers, grommets, and interior fittings. We work with a wide range of aerospace-grade thermoplastics and engineering materials such as PEEK, PEI (Ultem), PPS, PA6/PA66, PC, and flame-retardant ABS or PC/ABS blends to meet stringent performance, safety, and environmental standards.

To enhance durability and functionality, we offer advanced processing and finishing options such as insert molding, overmolding, ultrasonic welding, EMI shielding coatings, and surface texturing. For parts requiring enhanced aesthetics or environmental resistance, we also provide post-molding services like painting, laser marking, and precision CNC finishing. Our injection molding processes support tight tolerances and consistent results, ideal for mission-critical components in aerospace interiors, electronics, and defense systems.

- Aircraft Interior Paneling

- Ventilation Ducts

- Cable Management Channels

- Aerodynamic Fairings

- Radomes

- Access Panels

- Seat Components

- Avionics Housings

- Door Locking Systems

- Wire Harness Clips

- Thermal Insulation Panels

- Window Shades

- Overhead Bin Components

- Armrests

- Cockpit Control Knobs

- Switch Housings

- Lighting Fixtures

- Oxygen Mask Components

- Fastening Clips and Brackets

- EMI/RFI Shielded Enclosures

- Engine Component Covers

- Fuel System Housings

- Door Latches and Handles

- Airflow Control Valves

Aerospace Injection Molding Capabilities

Material Compatibility

We offer aerospace-grade plastics such as PEEK, Ultem, PPS, PC, and Nylon, with excellent performance in extreme environments.

Printing Accuracy

Tolerances are normally maintained within ±0.05mm, meeting the precision requirement for aerospace components.

Maximum Build Size

Can produce injection-molded parts up to 1000mm × 800mm × 500mm in overall size, well-suited for small- to mid-size aerospace parts.

Surface Finishing Options

Optional surface finishing like texturing, painting, plating, laser marking, and specialty coatings to enhance even further durability and appearance.

Delivery Time

Standard production lead time is 10-15 days, with expedited services available for urgent aerospace projects.

Massive Network

Our network includes certified manufacturing partners.

Explore Aerospace Injection Mold Parts We Manufactured

See our high-quality aerospace injection molding parts in action across diverse industries! Discover how Formioo delivers precision, strength, and consistency in real-world manufacturing projects.

Aerospace Injection Molding Tolerance

| Name | Tolerance Range |

|---|---|

| Standard Aerospace Injection Molding | +/- 0.2 mm to +/- 0.5 mm |

| Precision Aerospace Injection Molding | +/- 0.05 mm to +/- 0.2 mm |

| Complex Aerospace Parts | +/- 0.2 mm to +/- 0.5 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

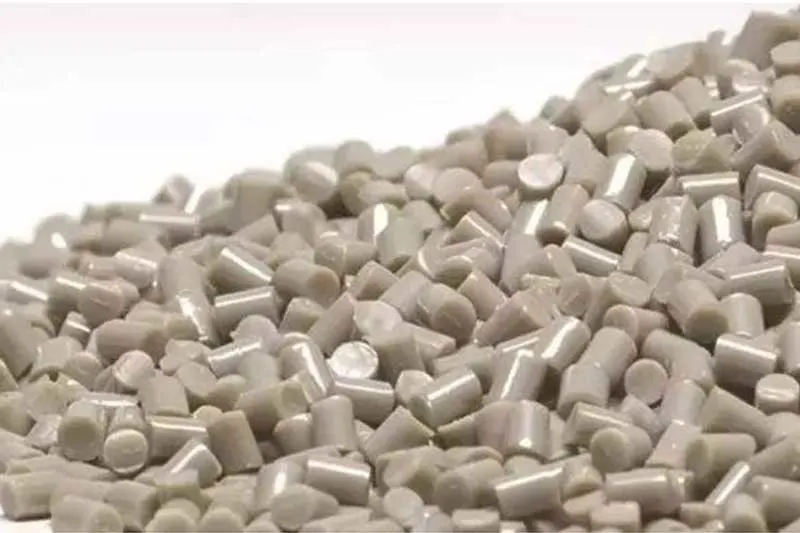

Aerospace Injection Molding Materials

ABS

ABS is an ideal choice for aerospace injection molding due to its excellent mechanical properties, impact resistance, and low processing temperature. It is easy to mold and suitable for manufacturing complex shapes. ABS finds widespread aerospace use in interior panels, housings, and prototyping. Interior trim on aircraft, for example, and electronic enclosures use ABS because of its strength-to-cost ratio.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte, or custom finishes

PC

PC is a suitable material for aerospace injection molding due to its excellent impact strength, transparency, and heat resistance. It can be easily injection-molded into complex geometries and may be employed in high-performance applications. PC is used extensively in the aerospace sector in materials like cockpit windows, light lenses, and transparent shields. Instrument panels and aircraft canopy windows, for example, routinely use PC due to their clarity and toughness.

- Mill Lead Time: Up to 4 days

- Color: Transparent, black, or custom finishes

PA

PA is the best choice one for aerospace injection molding because it exhibits higher moldability, wear resistance, and mechanical performance. It is suitable for making complex and tough parts. PA is used widely in aerospace in gears, bearings, and structural parts. For example, aircraft landing gear components and connectors often make use of PA for durability and strength.

- Mill Lead Time: Up to 3 days

- Color: Natural, black, or custom finishes

POM

POM is an ideal choice for aerospace injection molding as it possesses high rigidity, low friction, and high dimensional stability. It can be molded into precision parts easily and is well-suited for mechanical components. POM has wide-ranging applications in aerospace in gears, sliders, and fasteners.For example, POM is used in aircraft control system parts’ wear resistance and accuracy.

- Mill Lead Time: Up to 4 days

- Color: Natural, black, or custom finishes

PEEK

PEEK is the perfect material for aerospace injection moulding due to its high strength, heat resistance (up to 250°C), and chemical stability. It is a comparatively easy material to mould and very well-suited for the manufacturing of complex high-performance components. PEEK is being widely used in aerospace applications in engine components, bearings, seals, and structural components. Aircraft fuel system seals and engine housings, for example, often use PEEK for strength and precision.

- Mill Lead Time: Up to 5 days

- Color: Natural, black, or custom finishes

PPS

PPS is a great PPS aerospace injection molding material with its high chemical resistance, thermal stability, and dimensional stability. It can be molded into precise components and severe environment-friendly. PPS has widespread usage in aerospace in fuel system components, electrical connectors, and pump components. For example, aircraft fuel system valves and electrical housings contain PPS because of its reliability.

- Mill Lead Time: Up to 5 days

- Color: Natural, black, or custom finishes

PEI

PEI is an ideal material for aerospace injection molding as it possesses high strength, flame retardance, and high-temperature property retention. It is easily moldable into complex shapes and is suitable for critical applications. PEI is used to a great extent in aerospace applications for interior components, electrical connectors, and insulating components. Insides of aircraft cabins and electrical housings, for example, often make use of PEI for strength and flame retardancy.

- Mill Lead Time: Up to 4 days

- Color: Amber, black, or custom finishes

PSU

PSU is ideal for aerospace injection molding as it has high thermal stability, transparency, and resistance to hydrolysis. It is easy to mold into precision parts and suitable for demanding environments. PSU is widely used in aerospace for fluid handling components, electrical insulators, and transparent covers. For example, aircraft fluid system parts and cockpit displays often use PSU for its reliability.

- Mill Lead Time: Up to 5 days

- Color: Transparent, amber, or custom finishes

PI

PI is an ideal candidate for aerospace injection molding since it has better thermal stability, mechanical strength, and wear resistance. It has high compatibility with high-temperature applications and complex geometries. PI is used extensively throughout aerospace applications in a wide range of bearings, seals, and insulation components. Jet engine bearings and thermal insulation components, for example, often take advantage of PI for toughness.

- Mill Lead Time: Up to 6 days

- Color: Natural, brown, or custom finishes

Finishing Options for Aerospace Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Chem Film | Aluminum, Titanium, Stainless Steel | Clear, gold | Media Blasting, Tumbling, Type II Anodizing, Type III Anodizing with PTFE |

|

Powder Coating | Aluminum, Steel, Titanium | Wide range (depends on powder) | Electrostatic Spray, Curing Oven |

|

Anodizing | Aluminum, Titanium | Clear, Black, Custom | Electrolytic Process |

|

Polishing | Titanium, Aluminum, Stainless Steel | Bright, Mirror-like finish | Polishing Wheels, Buffing Compounds |

|

Electroplating | Aluminum, Steel, Titanium | Silver, Chrome, Gold, etc. | Electrolytic Process |

|

Laser Etching/Marking | Aluminum, Titanium, Stainless Steel | Natural, Black | Laser Machines |

|

Vibratory Finishing | Aluminum, Steel, Titanium | Matte, Metallic | Vibratory Tumblers |

|

Brushing | Stainless Steel, Aluminum | Natural metallic finish | Abrasive Brushes, Mechanical Buffing |

|

Surface Sealing | Aluminum, Titanium, Stainless Steel | Clear, Glossy | Surface Sealing Coating |

|

Chromate Conversion Coating | Aluminum, Steel | Clear, Yellow, Olive Drab | Chemical Bath |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your Aerospace Parts Supplier Selection Ultimate Guide

Which aerospace parts supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our latest supplier guide.

Formioo Aerospace Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

What type of aerospace components do you manufacture?

We connect you with manufacturers that produce structural, exterior, interior, and functional aerospace components, including louvers, fenders, sensor housings, etc.

What materials are commonly used in aerospace injection molding?

Our supply chain utilizes high-performance plastics like PEEK, Ultem, PPS, and PC to create thin, heat-resistant, and tough components.

Do you provide certification of aerospace-grade components?

Yes, suppliers are AS9100 and ISO 9001:2015 certified, and material certifications can be made available on request.

Do you do prototyping and high-volume production?

Yes, suppliers are AS9100 and ISO 9001:2015 certified, and material certifications can be made available on request.

How do I get a quote for my aerospace injection molding project?

Simply send over your 3D files and specifications, and we’ll send over a competitive quote from our qualified supplier network.

Do you ship aerospace components overseas?

Yes, the suppliers do ship overseas, and we can help you with logistics so that you have your delivery planned.

Aerospace Injection Molding Resource

Are You Looking for aerospace injection molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.