Custom 2K Injection Molding Services

Formioo offers 2K injection molding services, supporting low to high-volume production with fast lead times, precise alignment, and strong material bonding in a single molding cycle.

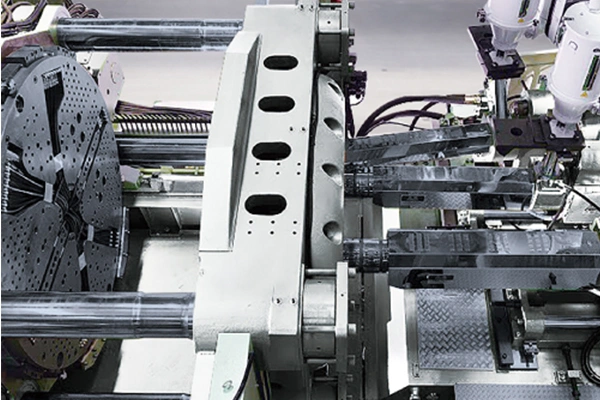

- 2K injection molding machines from 110 tons to 1,200 tons

- Strict quality control in accordance with EU and US standards

- More than 10 years of professional 2K injection molding service

- Precision 2K injection molding with tolerances as tight as ±0.01 mm

Reliable 2K Injection Molding Manufacturer from China

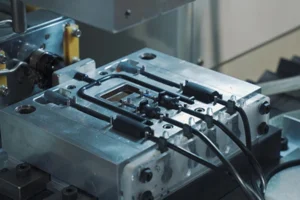

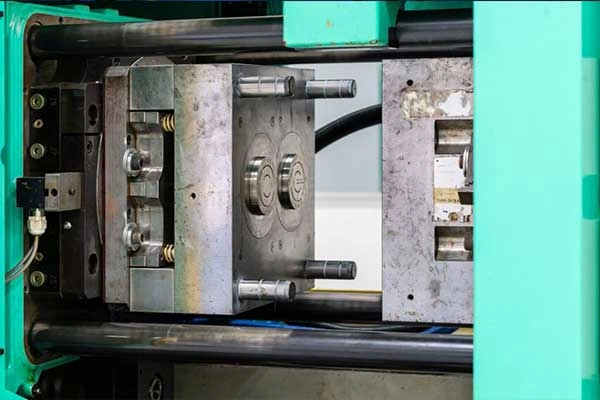

Formioo is a professional 2K injection molding manufacturer in China, offering high-quality multi-material and multi-color molding solutions for complex plastic parts. Our facility is equipped with advanced dual-shot molding machines capable of producing highly integrated components with tight tolerances, ideal for both rapid prototyping and scaled production.

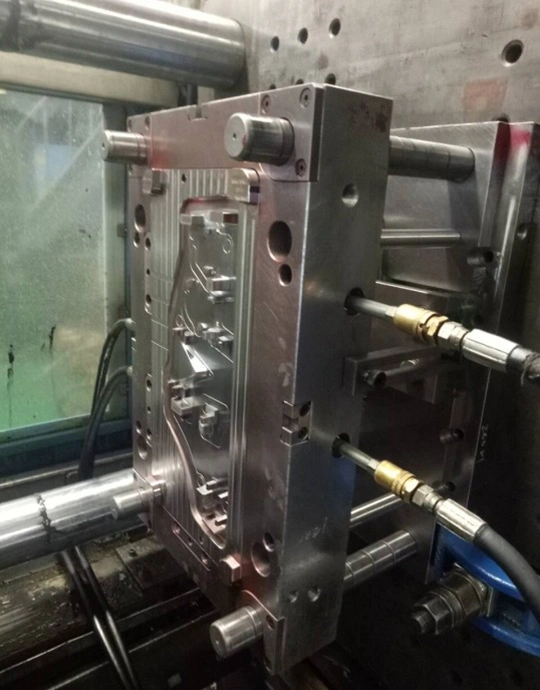

As a reliable injection molding service provider, we specialize in precise alignment between two different materials or colors within a single cycle, eliminating secondary operations and improving structural strength. Our engineering team provides expert DFM support to streamline your product development process, reduce time-to-market, and ensure optimal material compatibility for your specific application.

Since 2016, Formioo has delivered thousands of dual-shot molded parts each year to customers across the automotive, medical, consumer electronics, and industrial sectors. Our flexible production capacity allows us to handle everything from short-run prototype batches to high-volume manufacturing with consistent quality and competitive lead times.

Our 2K Injection Molding Services

Formioo’s 2K injection molding capabilities cover a full range of advanced techniques, including overmolding, insert molding, sequential two-shot molding, and co-injection molding. These processes allow us to mold two different materials or colors into a single component in one cycle, ideal for creating complex, multi-functional parts with enhanced performance and aesthetics. We work with a wide range of thermoplastics, elastomers, and engineering resins such as PC, ABS, TPU, TPE, PA, and PBT, ensuring reliable adhesion and durability across material combinations.

To enhance the functionality and finish of your dual-shot molded parts, we offer multiple post-processing options, including ultrasonic welding, heat staking, precision trimming, and surface texturing. Our molding operations achieve dimensional tolerances as tight as ±0.01 mm, depending on material and geometry. All parts are rigorously inspected using advanced measuring systems such as CMM and optical projectors to ensure consistency, precision, and full compliance with your design specifications.

Overmolding is secondary material accurate molding on a pre-existing substrate to enhance product performance and esthetics.

Insert molding integrates pre-made components into the mold cavity, then injects a secondary material for a seamless multi-material assembly.

Sequential two-shot molding injects two materials sequentially in distinct stages, offering accurate bonding and functional integration in intricate product designs.

Co-injection molding co-injects the core and skin materials together to create a multi-layered structure with optimum performance and least material consumption.

2K Injection Molding Capabilities

Material Compatibility

Capable of processing varied polymers like ABS, PP, PC, and others to fit different production needs.

Printing Accuracy

Capable of processing varied polymers like ABS, PP, PC, and others to fit different production needs.

Maximum Build Size

Capability to produce parts up to 1000mm × 600mm × 500mm, ideal for small to medium applications.

Surface Finishing Options

Various finishing methods such as painting, plating, and polishing are available.

Delivery Time

5-10 days typical lead time with option for rush services on projects needing swift attention.

Massive Network

We work with trusted injection molding suppliers.

Explore 2K Injection Molding Parts We Manufactured

From prototyping to mass production, our high-performance components consistently meet the toughest industry standards.

2K Injection Molding Tolerance

| Part Feature | Material | Tolerance |

|---|---|---|

| Wall Thickness | General Plastics | +/-0.05 mm |

| Length/Width/Height | General Plastics | +/-0.1 mm |

| Hole Diameter | General Plastics | +/-0.1 mm |

| Pin Position | General Plastics | +/-0.05 mm |

| Surface Finish | All materials | — |

| Color Registration | Multi-color Plastics | +/-0.1 mm |

| Assembly Fit | Plastics | +/-0.1 mm |

- *Formioo accommodates part lengths of up to 48", depending on the process. For larger dimensions, please reach out to us for inquiries. The tolerances listed represent minimums under ideal conditions; however, looser tolerances may be necessary based on the process, material selection, or part geometry.

2K Injection Molding Materials

PP

Polypropylene is an appropriate material for 2K injection molding due to its low density, chemical resistance, and good processability. It is also applied in automotive parts, household products, and packages. For example, the combination of PP and TPE is widely used for automotive bumpers, with rigid feel and soft touch.

- Mill Lead Time: Up to 3 days

- Color: Natural, black, or custom colors

PVC

PVC is prevalent in 2K injection molding due to its enhanced chemical resistance and impact strength. It is used widely in electrical and building parts. For instance, PVC is blended with TPE to produce hard yet flexible seals and pipe fittings that must be hard and flexible.

- Mill Lead Time: Up to 4 days

- Color: Clear, white, black, or custom colors

ABS

ABS is also a common material for 2K injection molding due to its impact resistance, mechanical properties, and good processing behavior. ABS is widely applied in automotive, electronics, and consumer goods. ABS is usually combined with soft-touch resins for automotive dashboards and electronic enclosures.

- Mill Lead Time: Up to 3 days

- Color: Black, neutral matte finish

PC

Polycarbonate is a strong plastic used in 2K injection molding ranging from applications that require impact strength and transparency to automotive, lighting, electronics, and medical uses. The most typical uses are found in the automotive industry. Polycarbonate, for example, is mixed with TPU to make tough automotive switch panels.

- Mill Lead Time: Up to 5 days

- Color: Clear, amber, or custom colors

PA

Polyamide (Nylon) is very wear-resistant, possesses high strength, and thus most appropriate for 2K injection molding. It is used extensively in such industries as automobile, electronics, and industry. For instance, nylon can be blended with soft-touch TPE for uses such as automotive connectors demanding both strength as well as sealability.

- Mill Lead Time: Up to 7 days

- Color: Natural, black, or custom colors

PET

Polyester is used in 2K injection molding due to the properties of strength, abrasion resistance, and dimensional stability. Automotive, consumer goods, and electronics are the most common uses of polyester. Polyester is also blended with elastomers to produce automotive parts that are resilient, flexible, for example, seatbelt assemblies.

- Mill Lead Time: Up to 5 days

- Color: Clear, black, or custom colors

PU

Polyurethane is a versatile material used in 2K injection molding due to its high wear resistance, flexibility, and durability. It is commonly used for automotive, industrial, and medical applications. For example, polyurethane is used in automotive suspension parts when combined with rigid materials like PA to provide shock absorption and high resilience.

- Mill Lead Time: Up to 7 days

- Color: Transparent, black, or custom colors

TPU

TPU is a wear-resistant, elastic compound ideally suited for 2K injection molding with high tear resistance and elasticity. TPU is most commonly applied in automotive, medical, and consumer product uses. For example, TPU is often blended with rigid materials like ABS or polycarbonate for mobile phone case and automotive parts applications.

- Mill Lead Time: Up to 5 days

TPV

TPV is a high-performance material that is applied in 2K injection molding, which transfers the characteristics of vulcanized rubber and thermoplastics. TPV is utilized in automotive and industrial applications for items that require durability and flexibility. For example, TPV is mixed with a hard plastic like PP or ABS to produce weather-resistant seals and gaskets for external automotive applications.

- Mill Lead Time: Up to 6 days

- Color: Black, gray, or custom colors

Finishing Options for 2K Injection Molding

| Name | Applicable Materials | Colors | Can Be Applied with | |

|---|---|---|---|---|

|

Polishing | Plastic, Rubber, Metal | — | Buffing, Tumbling |

|

Electroplating | Plastic, Metal | Chrome, Gold, Silver | Electroplating Bath |

|

Anodizing | Aluminum, Metal | Clear, Black, Gold | Media Blasting, Tumbling, Anodizing |

|

Powder Coating | Plastic, Metal | Custom Colors | Spray Application |

|

Painting | Plastic, Metal | Custom Colors | Spray, Dip, or Brush Application |

|

Laser Etching | Plastic, Metal | — | Laser Machines |

|

UV Coating | Plastic, Rubber | Glossy, Matte | UV Curing Process |

|

Silk Screening | Plastic, Rubber | Multiple | Manual or Automated Process |

|

Bead Blasting | Plastic, Metal | — | Sandblasting, Abrasive Blasting |

|

Surface Texturing | Plastic, Rubber | — | Mold Texturing, Laser Etching |

- *We offer a range of additional finishing options, including chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. If you require finishes for materials not mentioned here, please reach out to us directly.

Your 2K Injection Molding Supplier Selection Ultimate Guide

Which 2K injection molding supplier is ideal for your needs? What 3D printing material has excellent tensile strength? Try Materials. Download our lasted supplier guide.

Formioo 2K Injection Molding FAQs

We collect a lot of FAQs from our real clients, and please check out our FAQ page. For more information about Formioo Company, you can also download our company E-catalogue brochure.

How do I obtain a quotation for my project??

Simply email or send us your design specifications to upload through our website and we will quote competitively straight away.

What is your normal lead time?

Our normal lead time is 5-10 working days, but if timing is tight, this can be accelerated.

Do you produce small orders or prototypes?

Yes. We accept small runs and prototypes and can ramp up for mass production if necessary.

How do I send my design files?

You can upload your files through our website or send them to us directly for verification.

How do we process payments?

We normally take an advance deposit with the balance paid on delivery and would be happy to negotiate more flexible terms.

Do you provide after-sales support?

Yes, our customer service team is happy to help you with any queries or issues once you are in production.

2K Injection Molding Resource

Are You Looking for 2K Injection Molding Manufacturers in China?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.